Correction method for instrument voltage transformer

A technology of voltage transformer and correction method, which is applied to instruments, measuring electrical variables, measuring devices, etc., can solve the problems of inability to calibrate the voltage transformer for instruments, manual operation of differential compensation, and high requirements for transformation accuracy, so as to save labor Operating time, elimination of magnetic measurement errors and capacitive coupling errors, effect of high conversion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

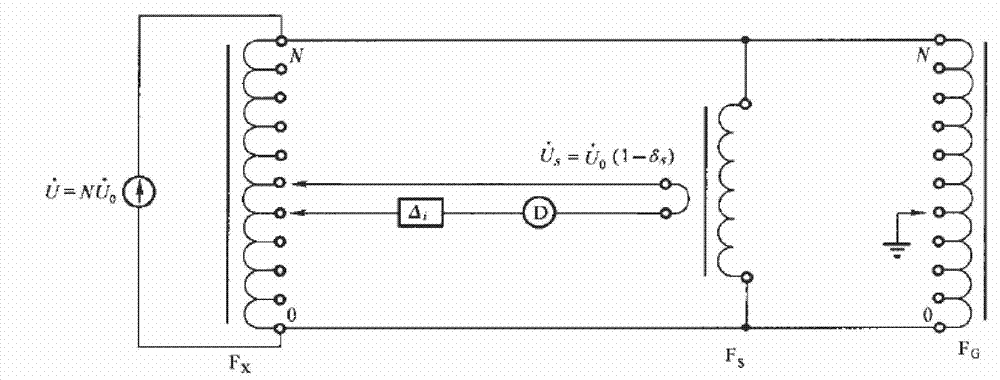

[0065] A calibration method for an instrument voltage transformer, comprising:

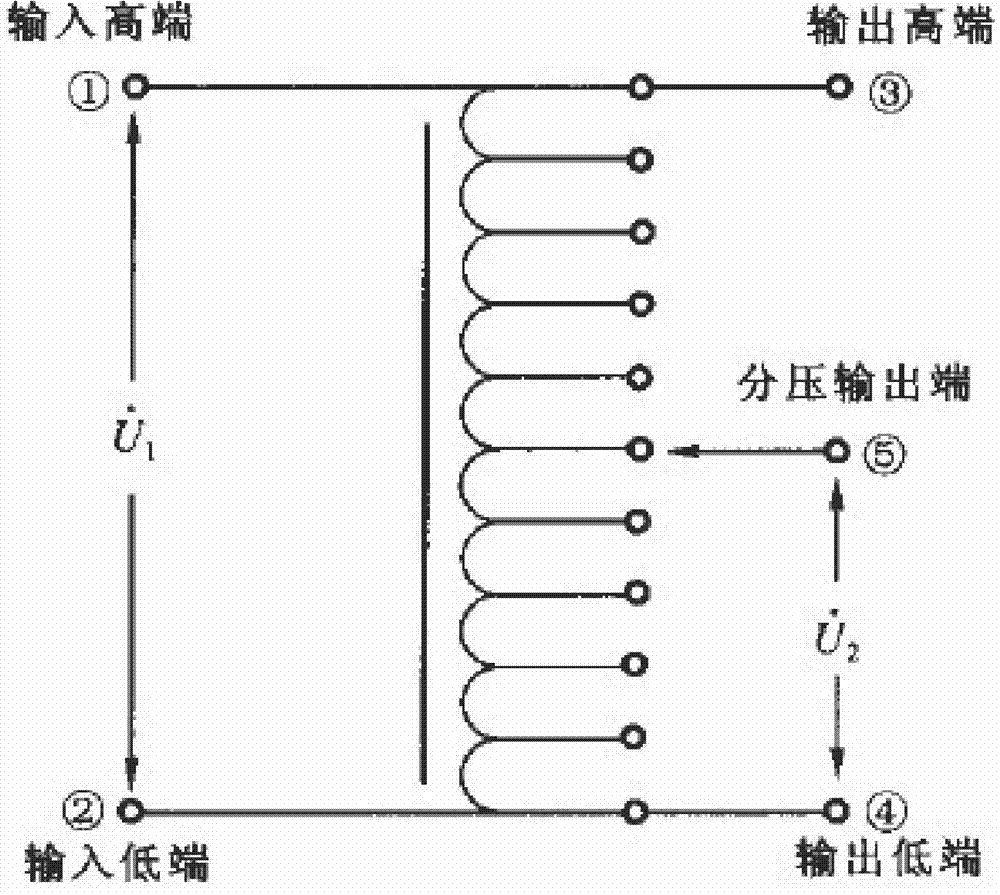

[0066] (1) First, according to the requirement of the transformation ratio of the instrument voltage transformer, combine the two induction voltage dividers through the main and auxiliary cascade connection, configure the transformation ratio gears of the main and auxiliary induction voltage dividers, and make the main and auxiliary cascade The combined transformation ratio is the same as that of a certain gear of the instrument voltage transformer.

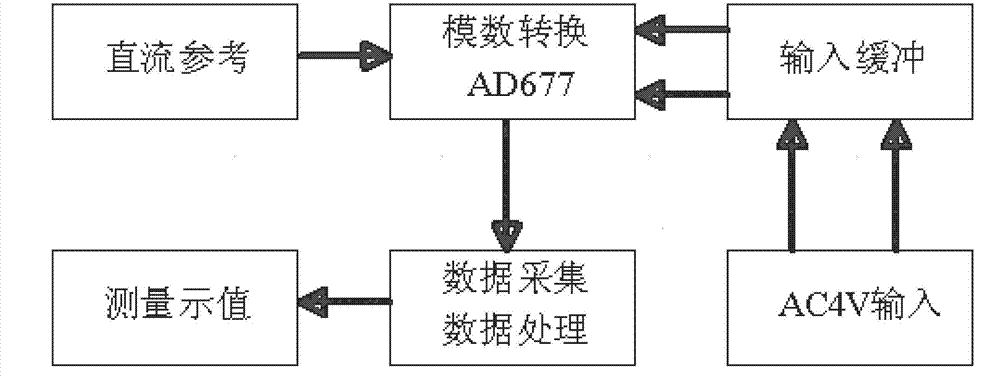

[0067] Wherein: the first corrected range of the instrument voltage transformer in this embodiment is the 100V / 4V range.

[0068] The voltage transformer (referred to as the sense divider) used in this embodiment is a segmented equipotential shielding induction voltage divider, which is specially designed for the working frequency from power frequency to 1000Hz. Theoretical analysis shows that: the transfer ratio error of the induction voltage divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com