Double-film PC (Polycarbonate) lens for optical display and preparation method thereof

An optical display and lens technology, applied in chemical instruments and methods, optics, optical components, etc., can solve the problem of late start of thin film materials, and achieve the effect of reducing secondary reflection and enhancing visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

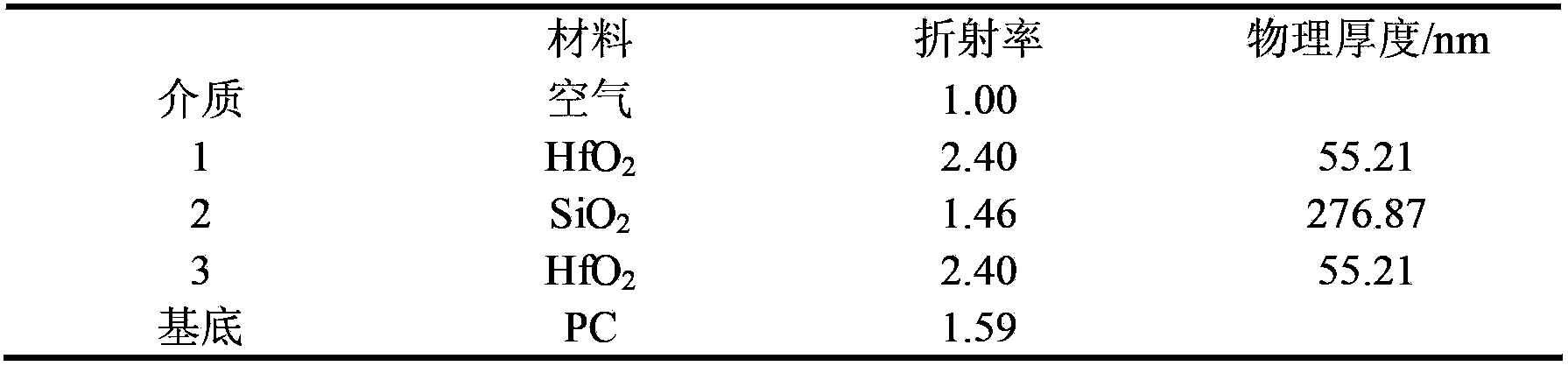

[0016] Based on PC, the reflective film adopts a film structure of (HL)^1H with a total of 3 layers. (Wherein, (HL)^1H means: the first layer of each cycle is a high refractive index material HfO with a thickness of 1 optical thickness 2 , the second layer is a low refractive material SiO with a thickness of 3 optical thicknesses 2 , a total of one period, and finally with H high refractive index material HfO 2 End; coating temperature is 50°C, coating pressure is 0.001MPa;

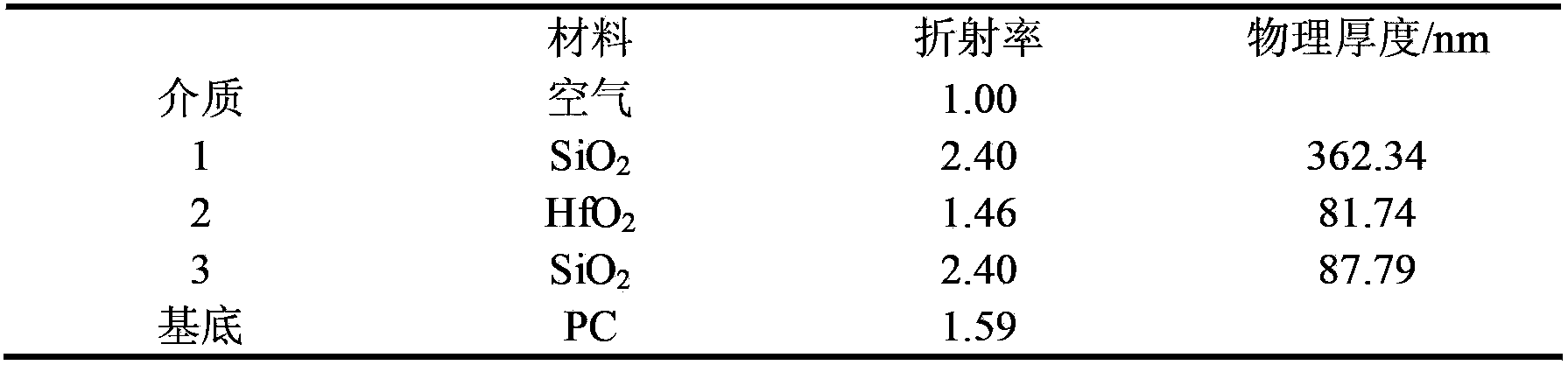

[0017] The anti-reflection coating adopts a film structure Sub|LHL| with a total of 3 layers. (Among them, Sub|LHL|A means: the first layer of each period is SiO with low refractive index 2 , the second layer is high refractive material HfO 2 , and finally with L low refractive index material SiO 2 End; coating temperature is 50°C, coating pressure is 0.002MPa;

[0018] Table 1 The refractive index and thickness of each layer of the three-layer reflective film

[0019]

[0020] Only the reflecti...

Embodiment 2

[0026] Based on PC, the reflective film adopts a film structure of (HL)^2H with a total of 5 layers. The coating temperature is 80°C, and the coating pressure is 0.003MPa;

[0027] The AR coating adopts a film structure Sub|LHLHLHL|A with a total of 7 layers; the coating temperature is 50°C, and the coating pressure is 0.003MPa;

[0028] Table 3 Refractive index and thickness of each film layer of five-layer film

[0029]

[0030] Only the reflection spectrum of the PC lens concave surface coated with reflective film was tested, and the highest reflectance of the reflection curve of the PC coated reflective film reached about 72%.

[0031] Table 4 Refractive index and thickness of each layer of seven-layer AR coating

[0032]

[0033] Only the reflection spectrum of the anti-reflection coating on the convex surface of the PC lens was tested. The highest reflectance of the reflection curve of the anti-reflection coating before and after PC coating does not exceed 1%, an...

Embodiment 3

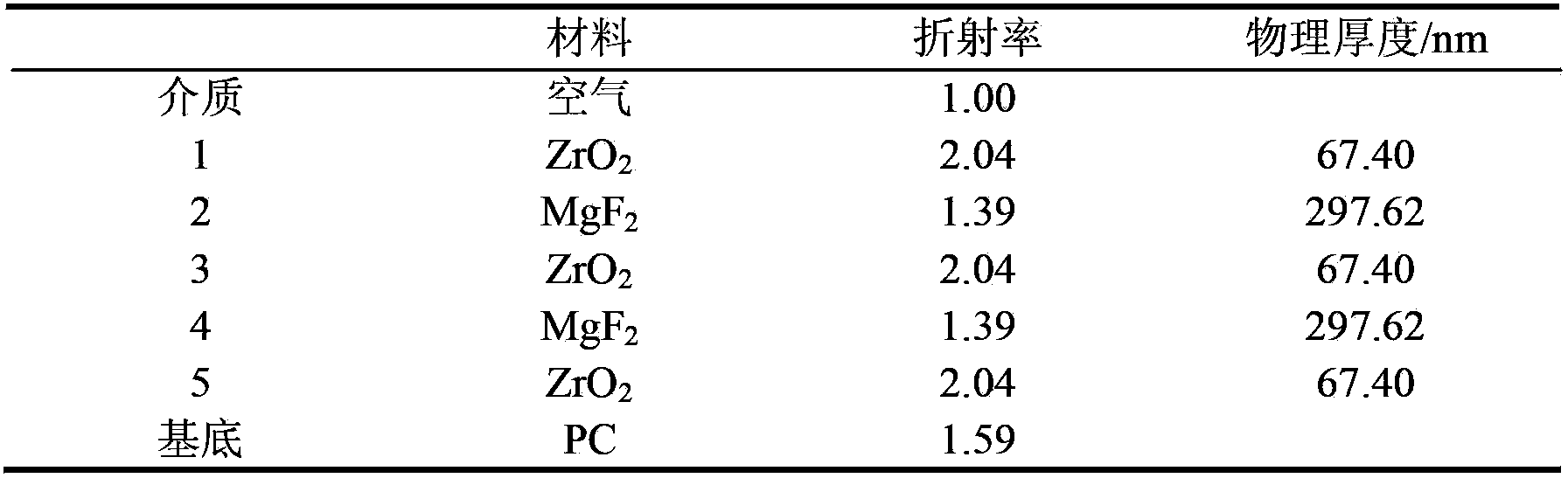

[0036] With PC as the substrate, the reflective film adopts a film structure of (HL)^5H with a total of 11 layers; the coating temperature is 80°C, and the coating pressure is 0.001MPa;

[0037] The anti-reflection coating adopts a film structure Sub|LHL|A with a total of 3 layers; the coating temperature is 80°C, and the coating pressure is 0.001MPa;

[0038] Table 5 Refractive index and thickness of each film layer of seven-layer film

[0039]

[0040] Only the reflection spectrum of the anti-reflection coating on the convex surface of the PC lens was tested, and the highest reflectance of the reflection curve of the reflection film after PC coating reached about 85%.

[0041] Table 6 The refractive index and thickness of each layer of the three-layer AR coating

[0042]

[0043] Only the reflection spectrum of the anti-reflection coating on the convex surface of the PC lens was tested. The highest reflectance of the reflection curve of the anti-reflection coating befor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com