Modeling method of etching yield in plasma etching process

A plasma and process technology, applied in the field of solving the etching yield model, can solve the problems of high measurement cost and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

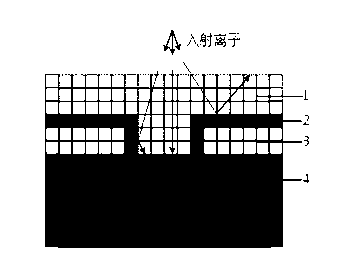

[0029] A modeling method of etching yield in a plasma etching process proposed by the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

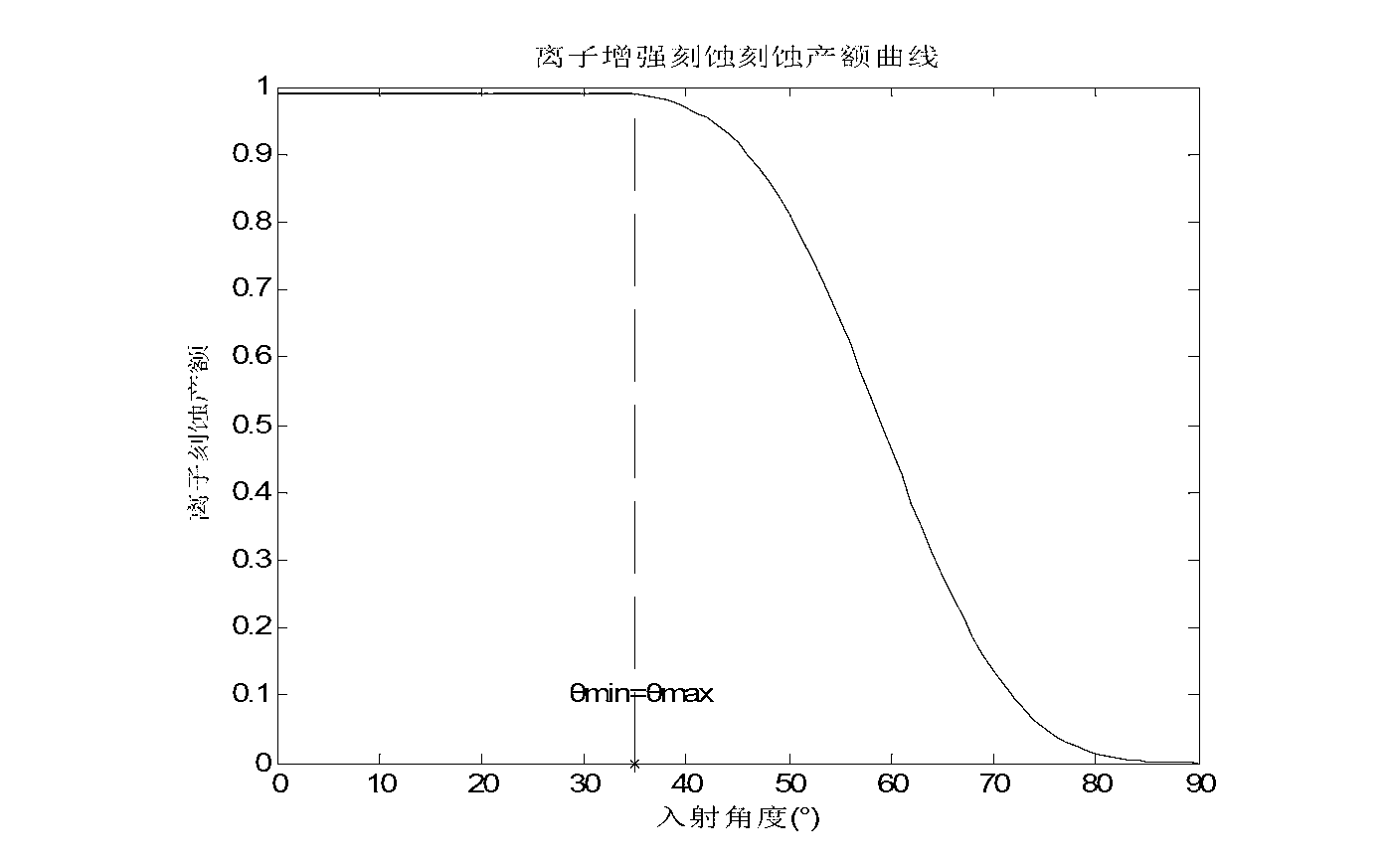

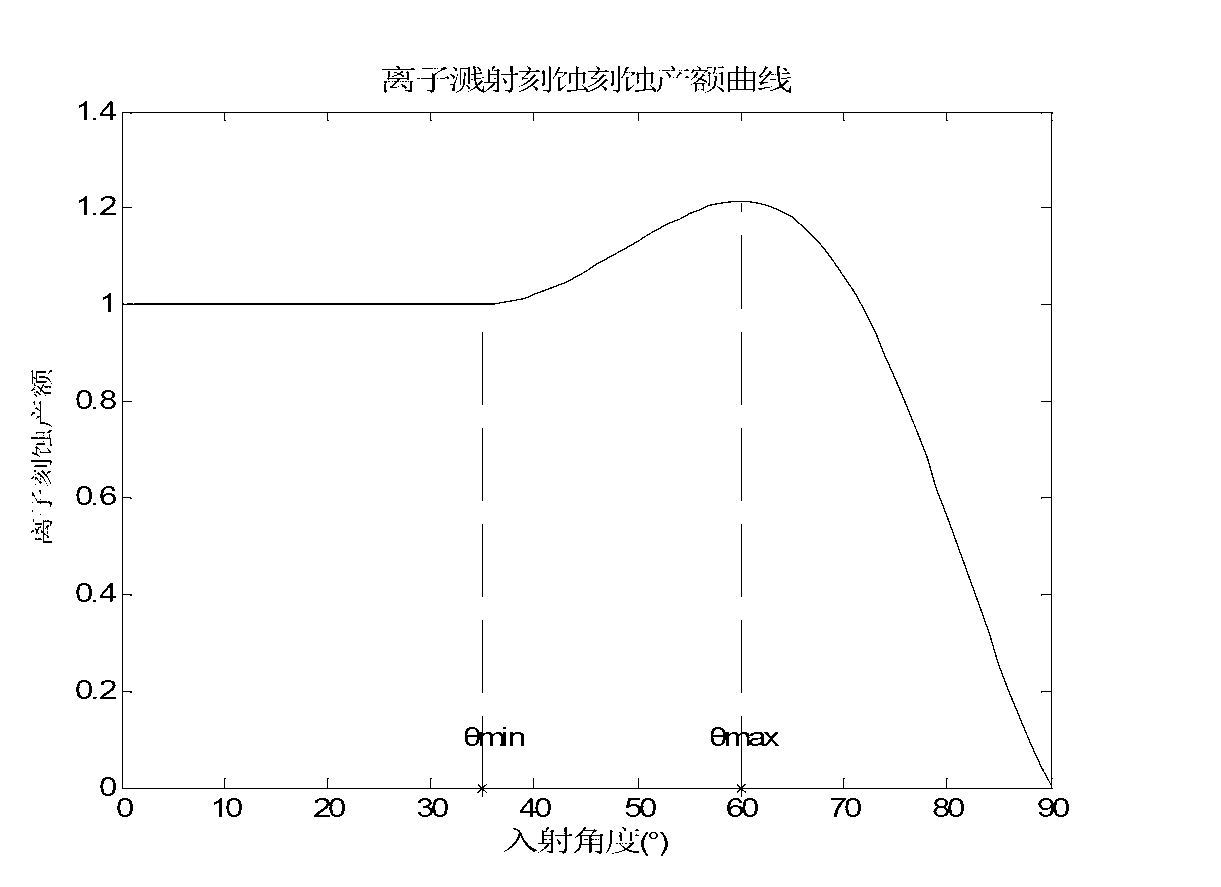

[0030] The overall process of the method embodiment of the present invention is as follows Figure 4 As shown, this embodiment proposes an etching yield model Y total The parameter means:

[0031]

[0032] The intermediate variables a and b in formula (1) are expressed as:

[0033] a = θ min tan ( θ max ) - θ max ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com