Fastener load-deformation curve numerical simulation method

A numerical simulation and load deformation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that are not suitable for general engineering personnel, time-consuming and labor-intensive, and needs, and achieve the goal of improving competitiveness in the international market, simulation Simple analysis method and high computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

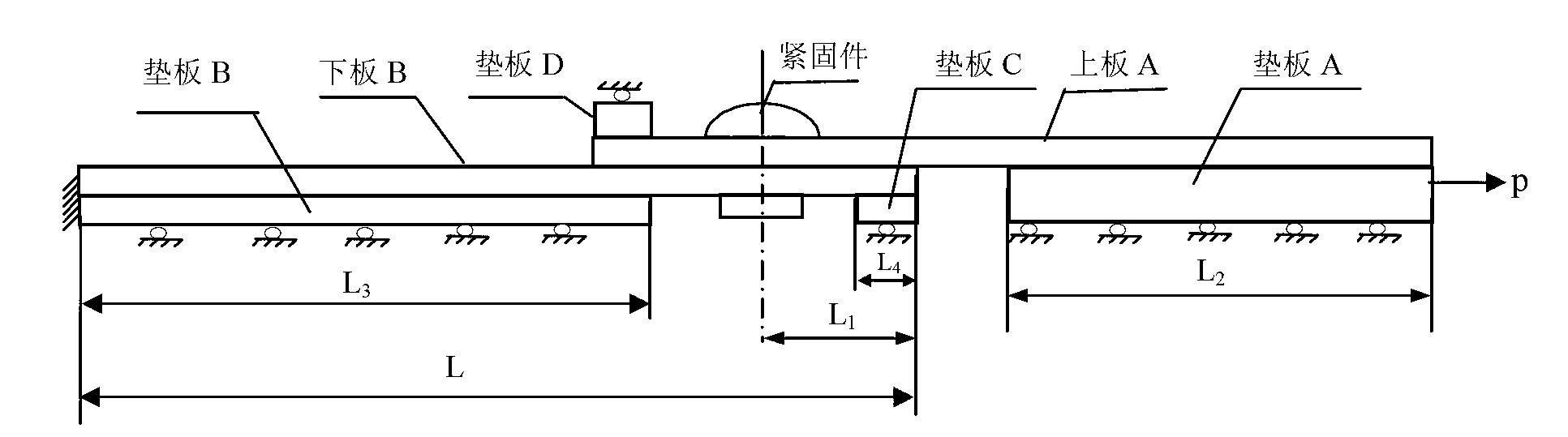

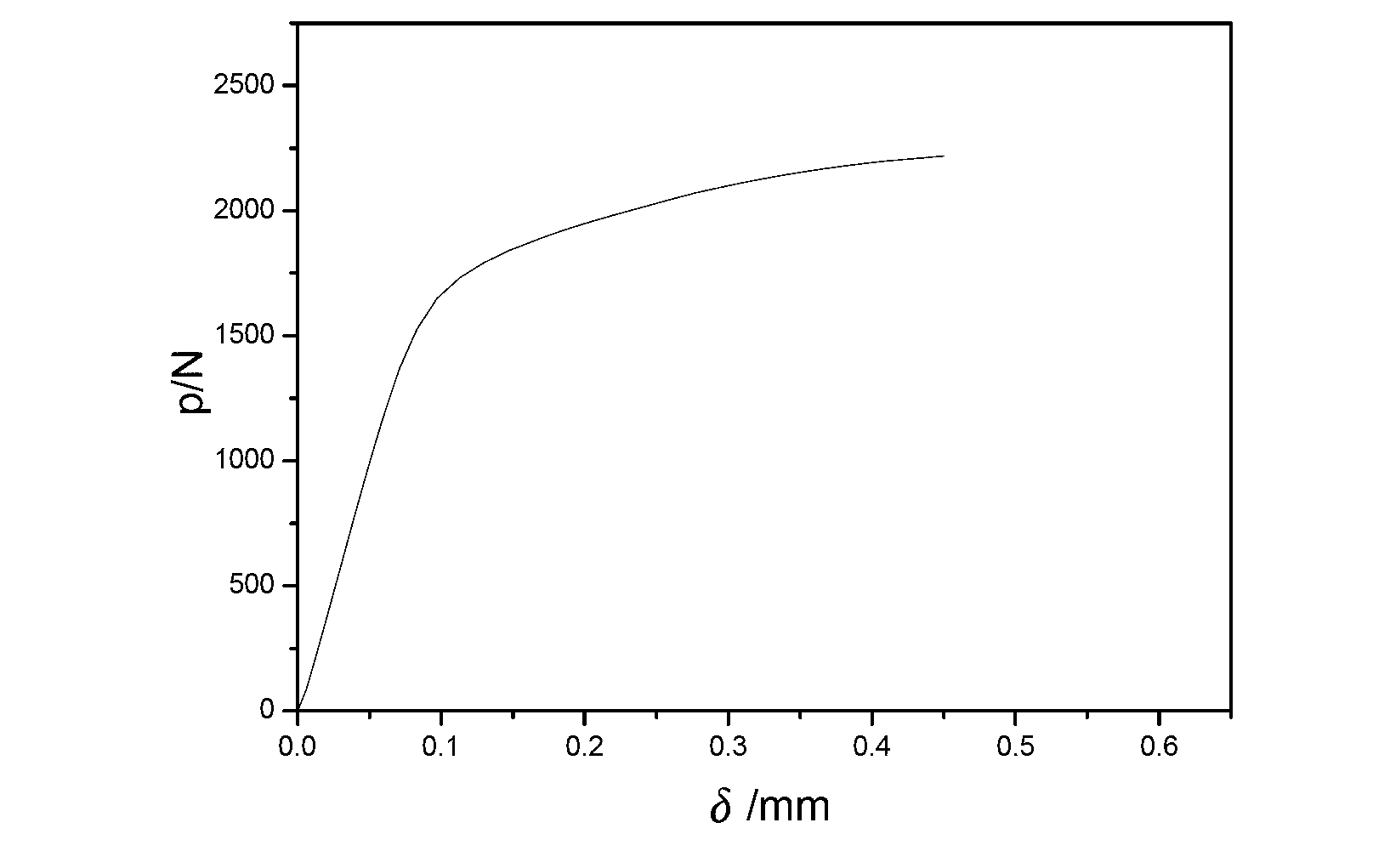

[0025] The length L of the upper plate A and the lower plate B is 37.5mm, and the distance L between their ends and the fasteners 1 =12.5mm, the lengths of backing plate A and backing plate B are L respectively 2 =10.0mm, L 3 =17.5mm; the length of backing plate C and backing plate D are both L 4 = 5.0 mm, width w = 20 mm for all panels. The grade of the fastener is GB867-67, and the diameter is φ=3mm.

[0026] Upper plate A thickness t 1 =1.8mm, the thickness of lower board B is t 2 =1.0mm, the thickness of backing plate A is 2.0mm, and the thickness of backing plates B, C, and D is 1.0mm.

[0027] The material of the upper and lower plates and fasteners is Ly12-CZ aluminum alloy, and the yield strength of the material is σ cy =427.8MPa, material elastic modulus E=77160MPa, material strengthening modulus E tan =11.2MPa, ultimate strength σ tu =539.6MPa, Poisson's ratio μ=0.305,

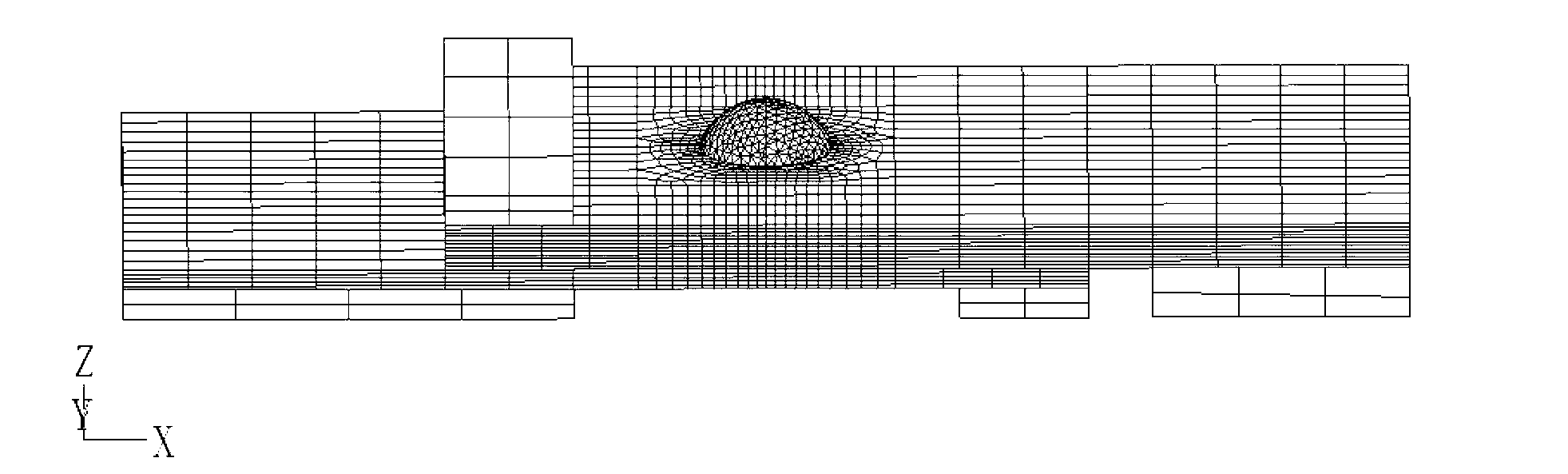

[0028] The finite element simulation model is realized according to step 2.

[0029] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com