Data conduction and positioning device for turnover light-emitting diode (LED) studio screen

A technology of conducting device and positioning device, which is applied to identification devices, instruments, etc., can solve the problems of data cable or wire damage, rigid display form, falling off of terminals, etc., and achieves long service life, convenient positioning and connection structure, and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

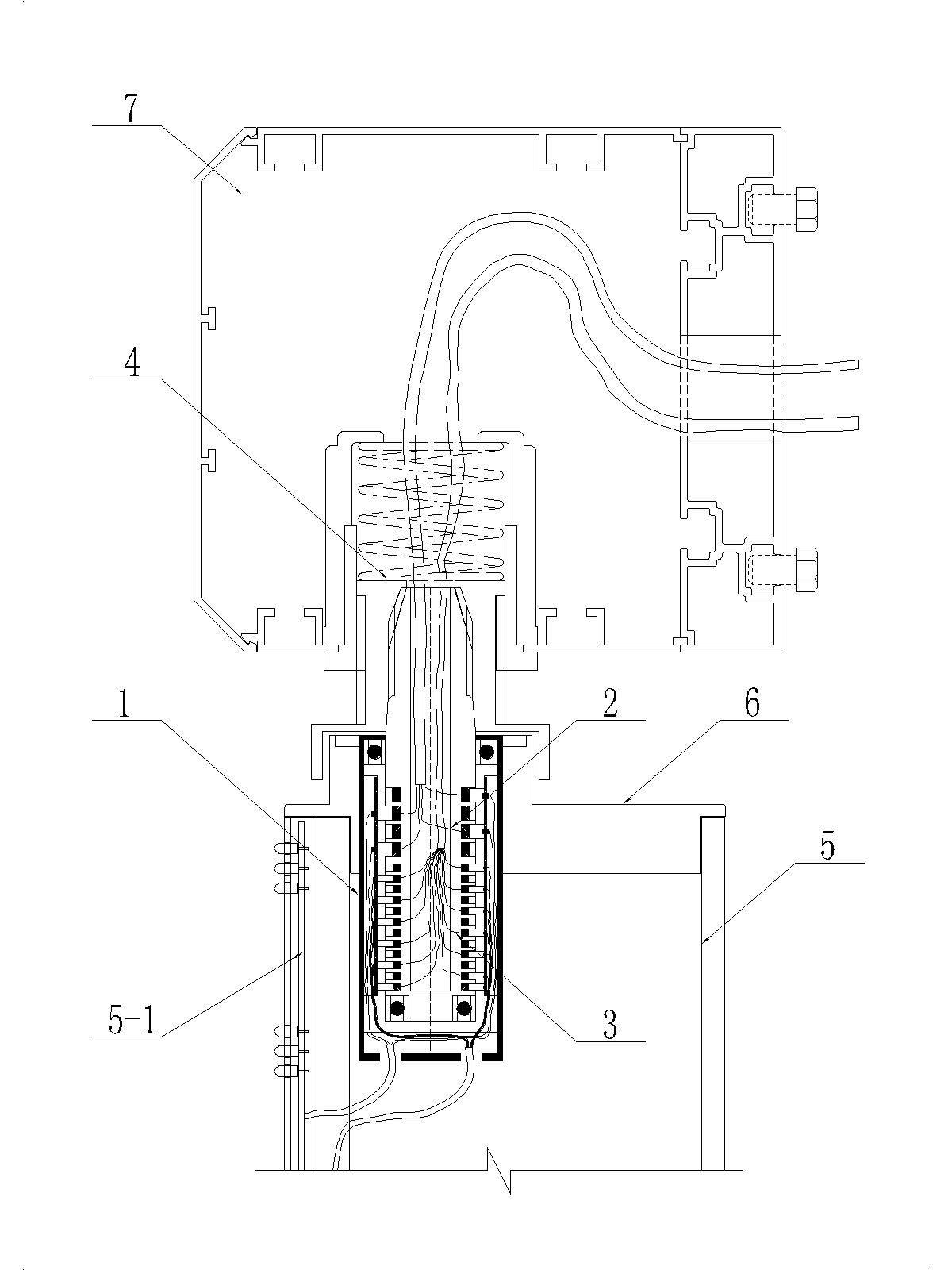

[0033] Data connection device (1) is implemented, such as figure 1 , The data conducting device (1) is installed on the upper port of the LED triangle module (5) through the triangular connecting plate (6) and connected with the positioning device (4) installed on the lower side plate (7) of the decorative frame, the LED The triangle module (5) rotates with the positioning device (4) as a rotation axis.

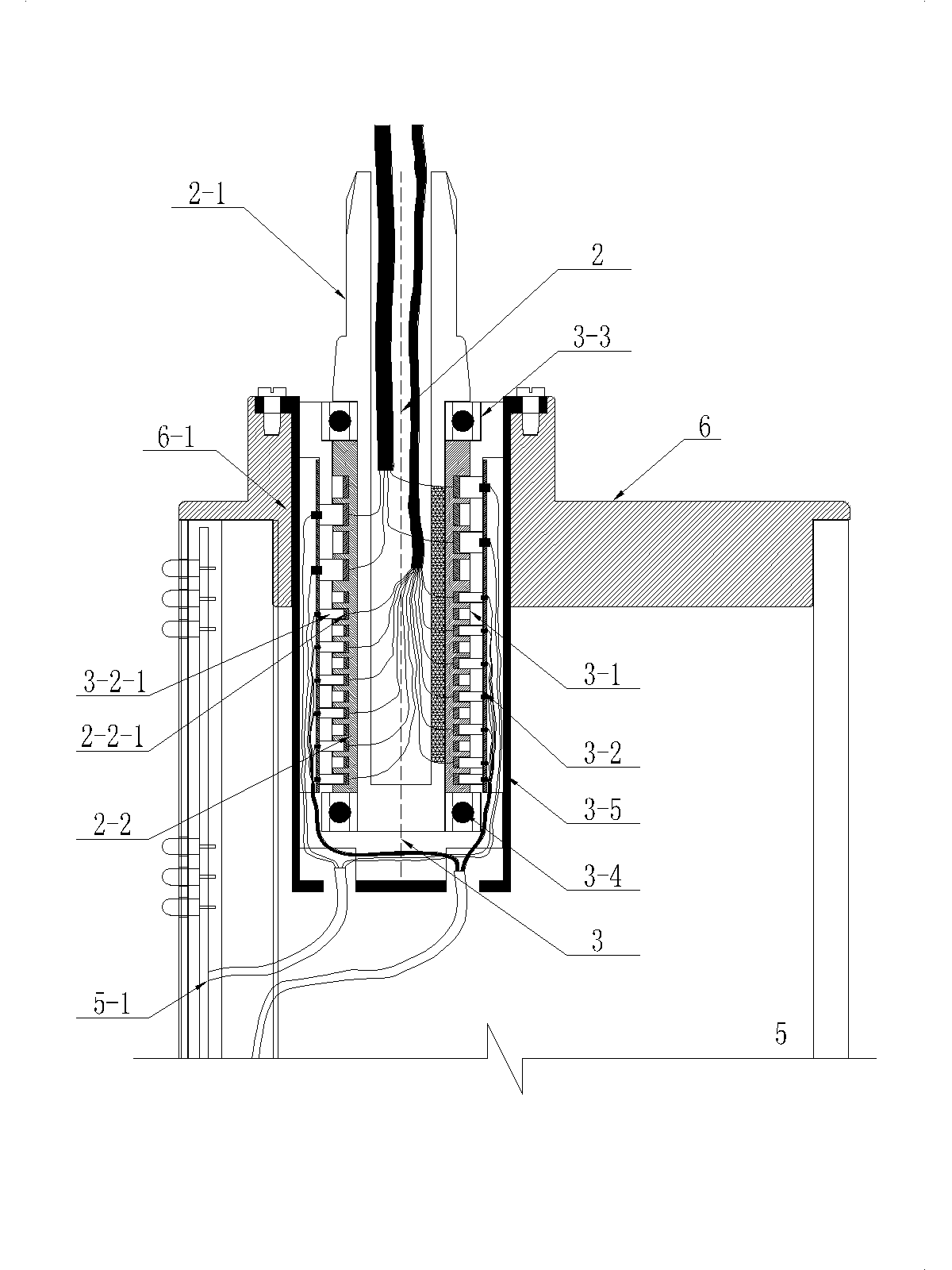

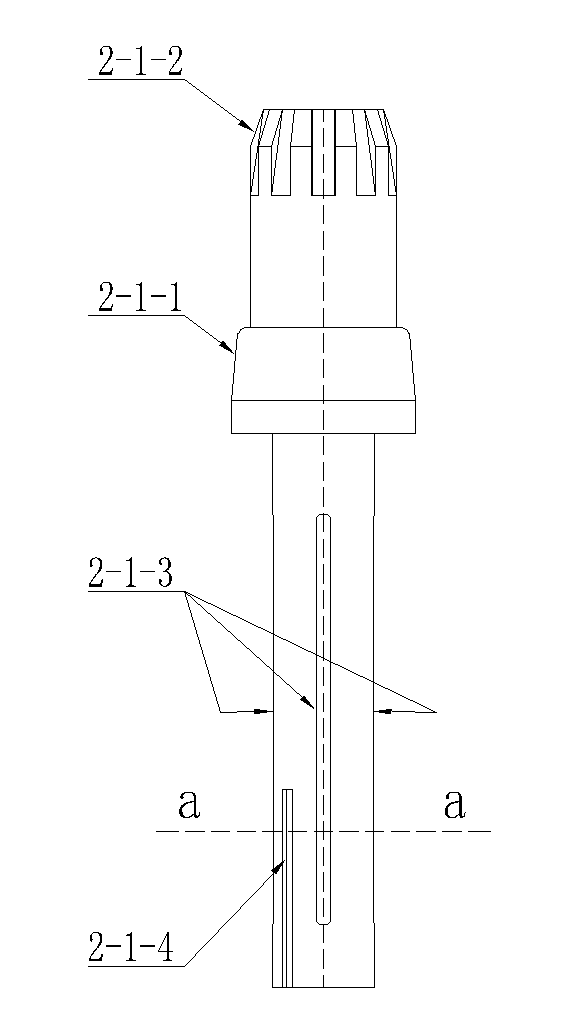

[0034] Such as figure 2 The data conducting device (1) includes a stator (2) and a rotor (3). One end of the positioning connecting shaft (2-1) is a positioning connecting end of the stator (2), and a combination is installed on the periphery of the other end Slip ring (2-2), the combined slip ring (2-2) has a data line lead to connect with external equipment; the rotor (3) is installed with a brush module inside the hollow bracket (3-1) (3-2), the brush module (3-2) also has a data cable led out to the inner cavity of the LED triangle module (5); a combined slip ring (2-2) is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap