Method for forming semiconductor integrated device

A technology of integrated devices and semiconductors, which is applied in the field of semiconductor integrated device formation, can solve the problems of many process steps and low integration, and achieve the effects of reducing costs, saving processes, and improving process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

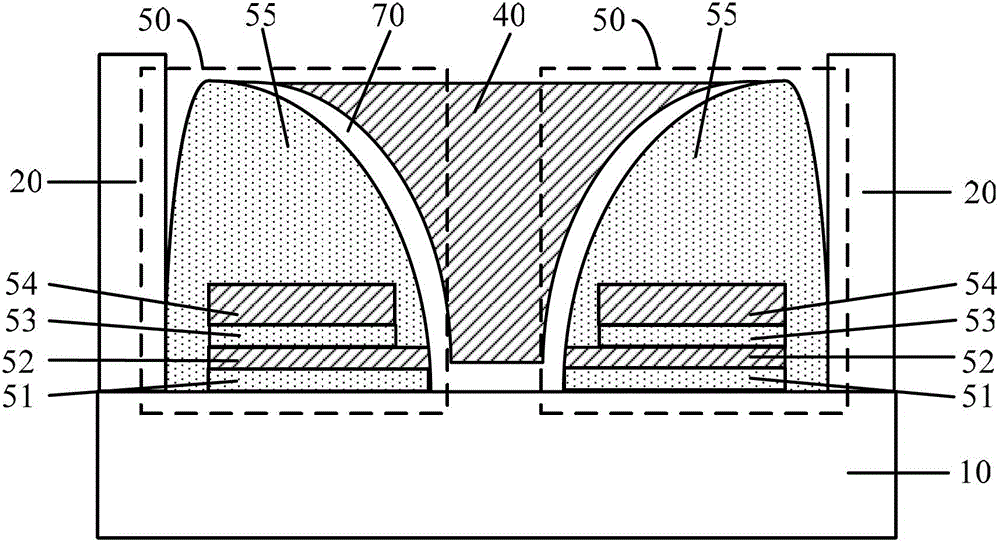

[0025] When the split-gate flash memory and the polysilicon resistor are formed using the existing process, the split-gate flash memory and the polysilicon resistor are manufactured separately, that is, after the split-gate flash memory is formed in a designated area, the split-gate flash memory A mask layer is formed on the surface, and then polysilicon resistors are formed in other areas. However, since the fabrication of the split-gate flash memory requires the deposition of multiple polysilicon layers to form control gates, floating gates or word lines, after the split-gate flash memory is formed, the multi-layer polysilicon layers in other regions are etched away, and then Forming another polysilicon layer to make polysilicon resistors results in a waste of material and an increase in process steps.

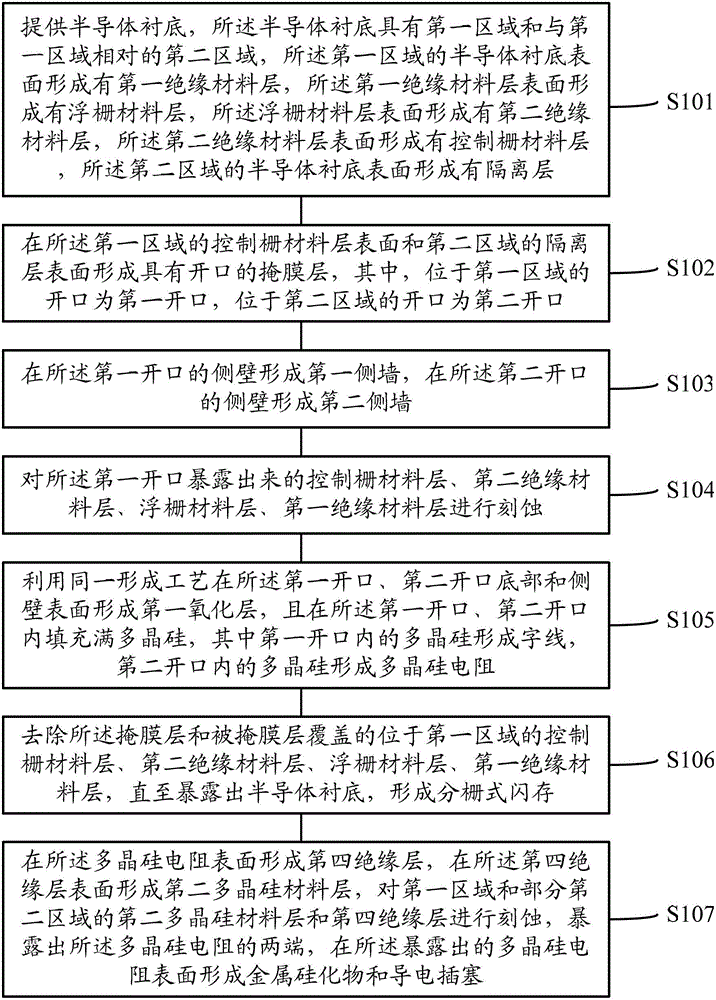

[0026] Therefore, an embodiment of the present invention provides a method for forming a semiconductor integrated device. A first sidewall is formed on the sidewall of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com