Etching equipment and crystal edge etching method

A technology of etching equipment and etching gas, which is applied in the manufacture of discharge tubes, electrical components, semiconductors/solid-state devices, etc., can solve problems such as shortening product life, reducing product yield, and damaging wafers, so as to improve service life, The effect of improving product yield and reducing crystal edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

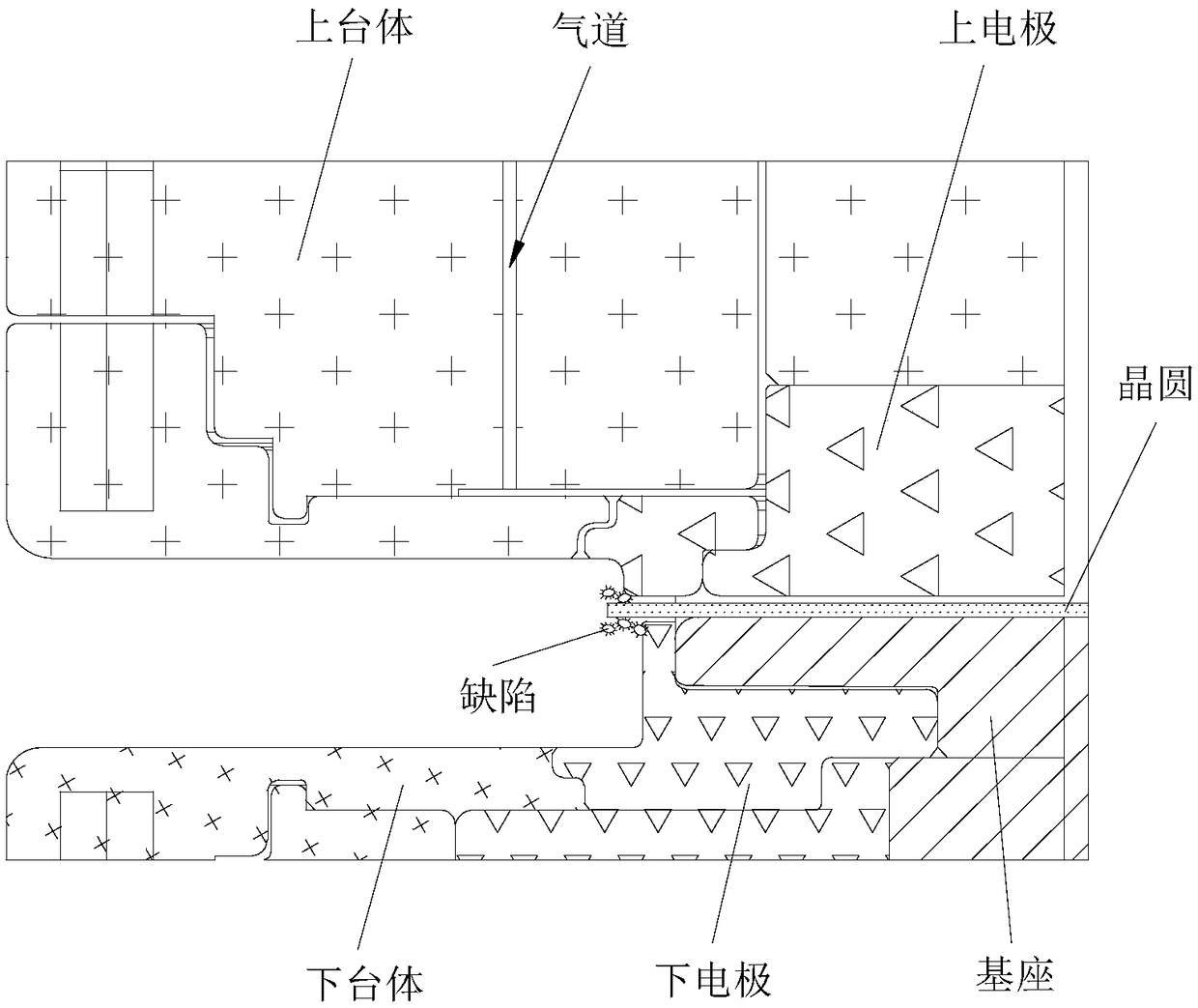

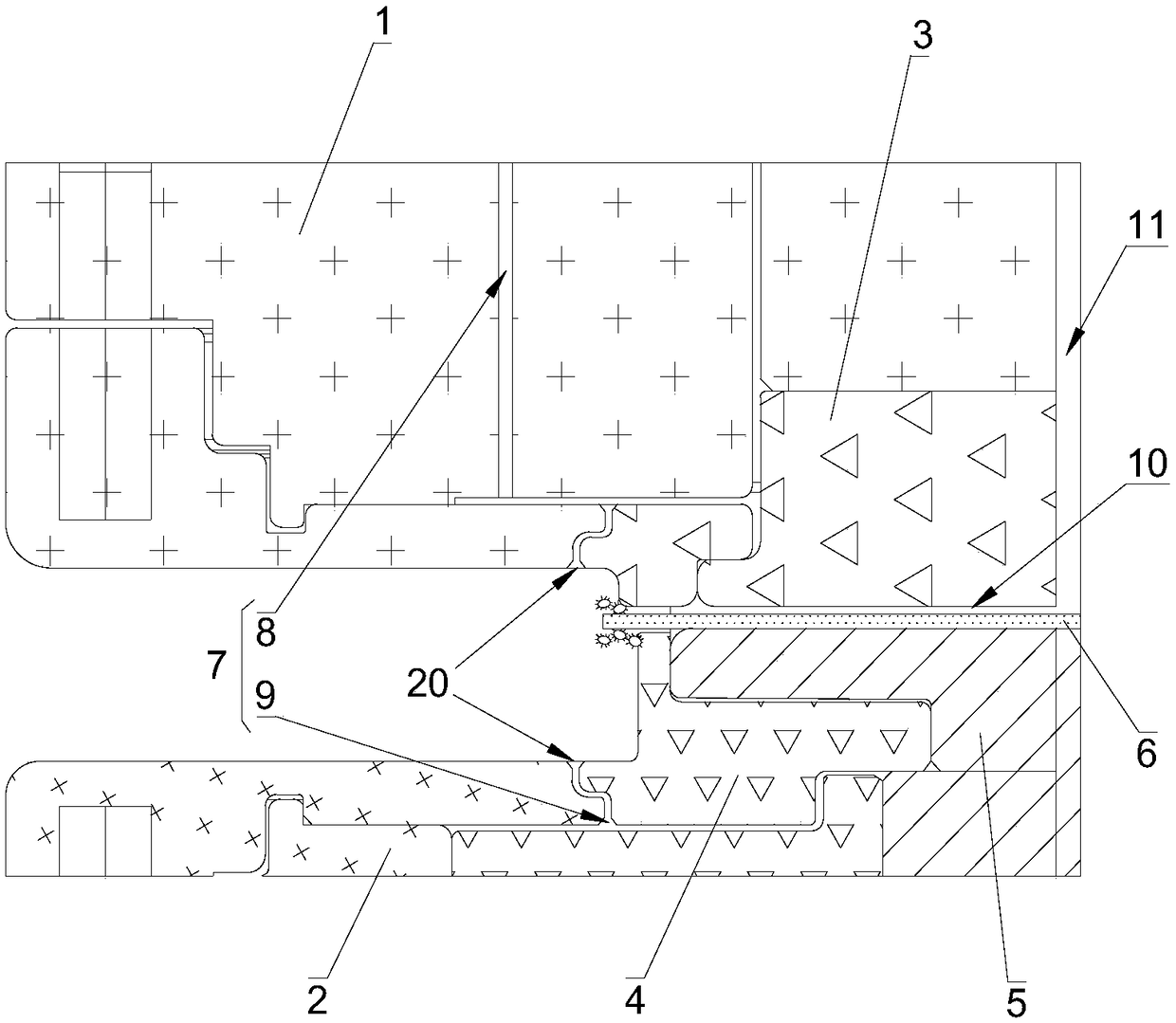

[0053] The first embodiment of the present invention provides an etching device, see figure 2 As shown, it includes an upper platform 1 , a lower platform 2 , an upper electrode 3 and a lower electrode 4 . The upper platform body 1 and the lower platform body 2 are arranged oppositely, and the upper electrode 3 and the lower electrode 4 are correspondingly arranged on the opposite sides of the upper platform body 1 and the lower platform body 2, and the lower electrode 4 is also provided with a substrate for supporting the wafer 6. Seat 5. The etching equipment also includes an etching gas supply assembly 7 , and the upper and lower edges of the wafer 6 are etched by the etching gas supply assembly 7 .

[0054] Using the etching equipment provided by the present invention, when performing edge etching, the wafer 6 is placed on the base 5, and the upper platform 1 drives the upper electrode 3 to move downward, covering and pressing the center of the wafer 6, and engraving Th...

Embodiment approach 2

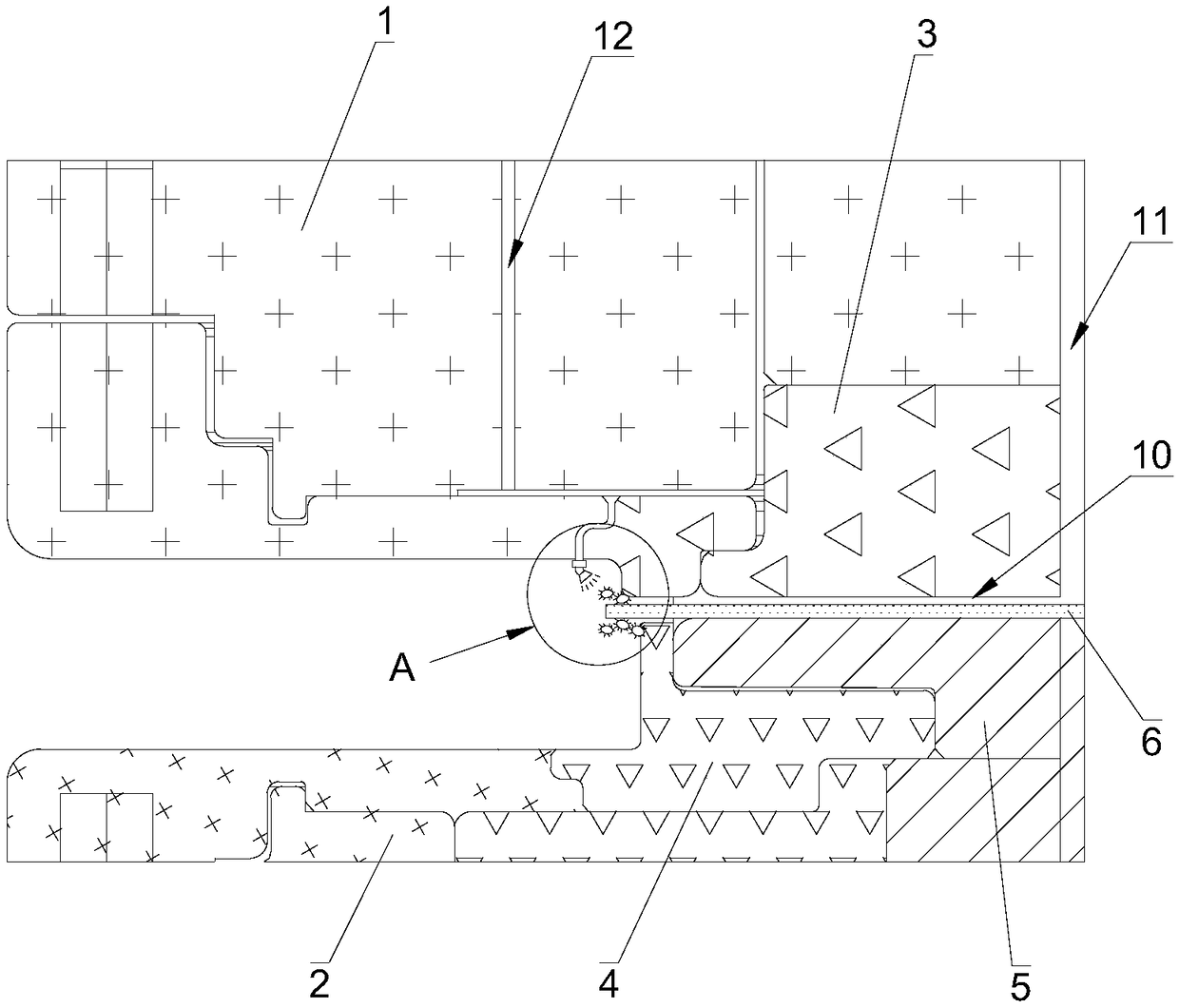

[0067] The second embodiment of the present invention provides an etching device. The main improvement of the second embodiment is that, in the second embodiment of the present invention, the combination image 3 , Figure 4 From the point of view, the etching gas supply assembly 7 includes a main gas source (the main gas source is an external gas source, for simple illustration, not shown in the figure) and a main gas channel 12 communicating with the main gas source. The main gas channel 12 communicates with The etching part 13, when performing edge etching, uses the main gas source to feed the etching gas into the main gas channel 12, and the etching gas reaches the upper and lower edges of the wafer 6 along the main gas channel 12 and through the etching part 13 And etch the upper and lower edges of the wafer 6 . Thereby reducing crystal edge defects and improving product yield.

[0068] In particular, the main gas channel 12 is a channel opened on the upper platform 1, ...

Embodiment approach 3

[0075] The third embodiment of the present invention provides an etching device. The main improvement of the third embodiment is that, in the third embodiment of the present invention, the combination Figure 7 with Figure 8From the view, the etching unit 13 includes two second shower heads 18 corresponding to the upper and lower edges of the wafer 6 respectively. When performing edge etching, the etching gas passes through the main gas channel 12 and passes through the two second shower heads 18 to reach the upper and lower edges of the wafer 6 respectively, thereby etching the upper and lower edges of the wafer 6 to reduce edge defects , Improve product yield.

[0076] see Figure 7 As shown, in order to flexibly adjust the injection volume of the etching gas, the etching gas supply assembly 7 further includes a regulating valve 19 . Preferably, the regulating valve 19 is a solenoid valve, and the regulating valve 19 is communicatively connected with the controller 16 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com