Method and system for processing polycrystalline silicon layer before forming of gate insulation layer

A gate insulating layer and polysilicon layer technology, which is applied in the field of polysilicon layer processing methods and processing systems, and can solve problems such as damage and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

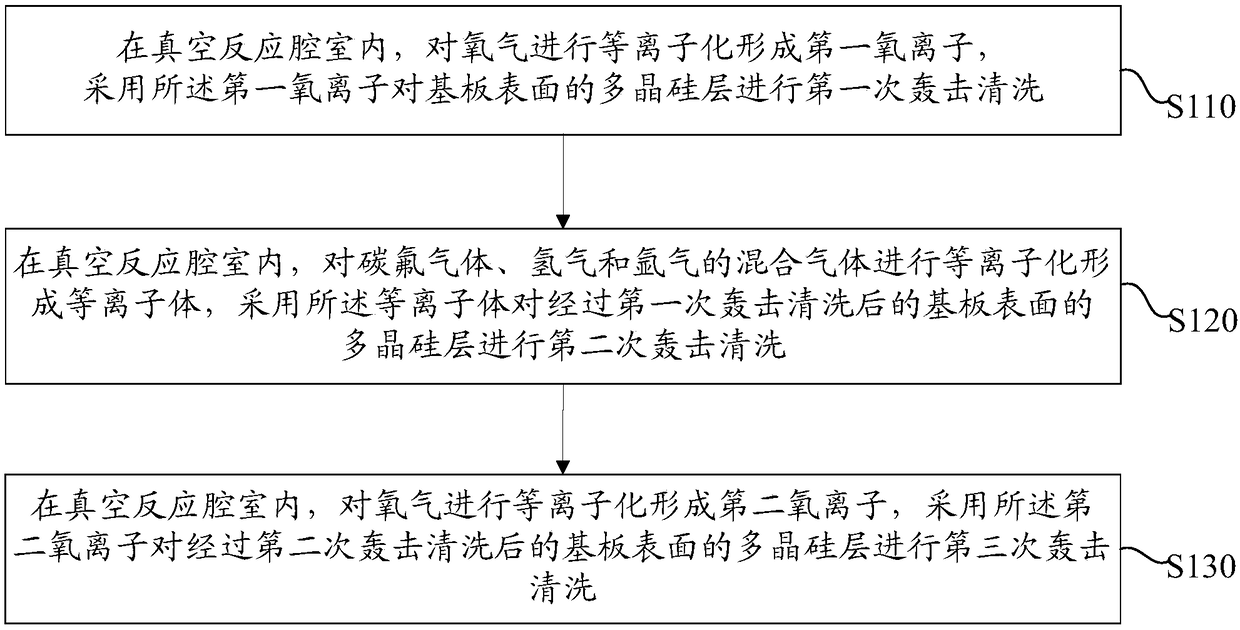

[0053] A polysilicon layer processing method before forming a gate insulating layer, which is applied before forming a gate insulating layer on a polysilicon layer of a substrate, the polysilicon layer processing method includes the following steps:

[0054] In the vacuum reaction chamber, oxygen is plasmatized to form first oxygen ions, and the polysilicon layer on the surface of the substrate is bombarded and cleaned for the first time by using the first oxygen ions; Among them, the flow rate of the oxygen is 1300 sccm, the radio frequency signal source (RF Source) that forms the first oxygen ion is 4000W, the radio frequency bias (RF Bias) is 2000W, and the duration of the first bombardment cleaning is 42 seconds, the pressure of the vacuum reaction chamber is 1Pa;

[0055] In the vacuum reaction chamber, the mixed gas of fluorocarbon gas, hydrogen and argon is plasmaized to form plasma, and the polysilicon layer on the surface of the substrate after the first bombardment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com