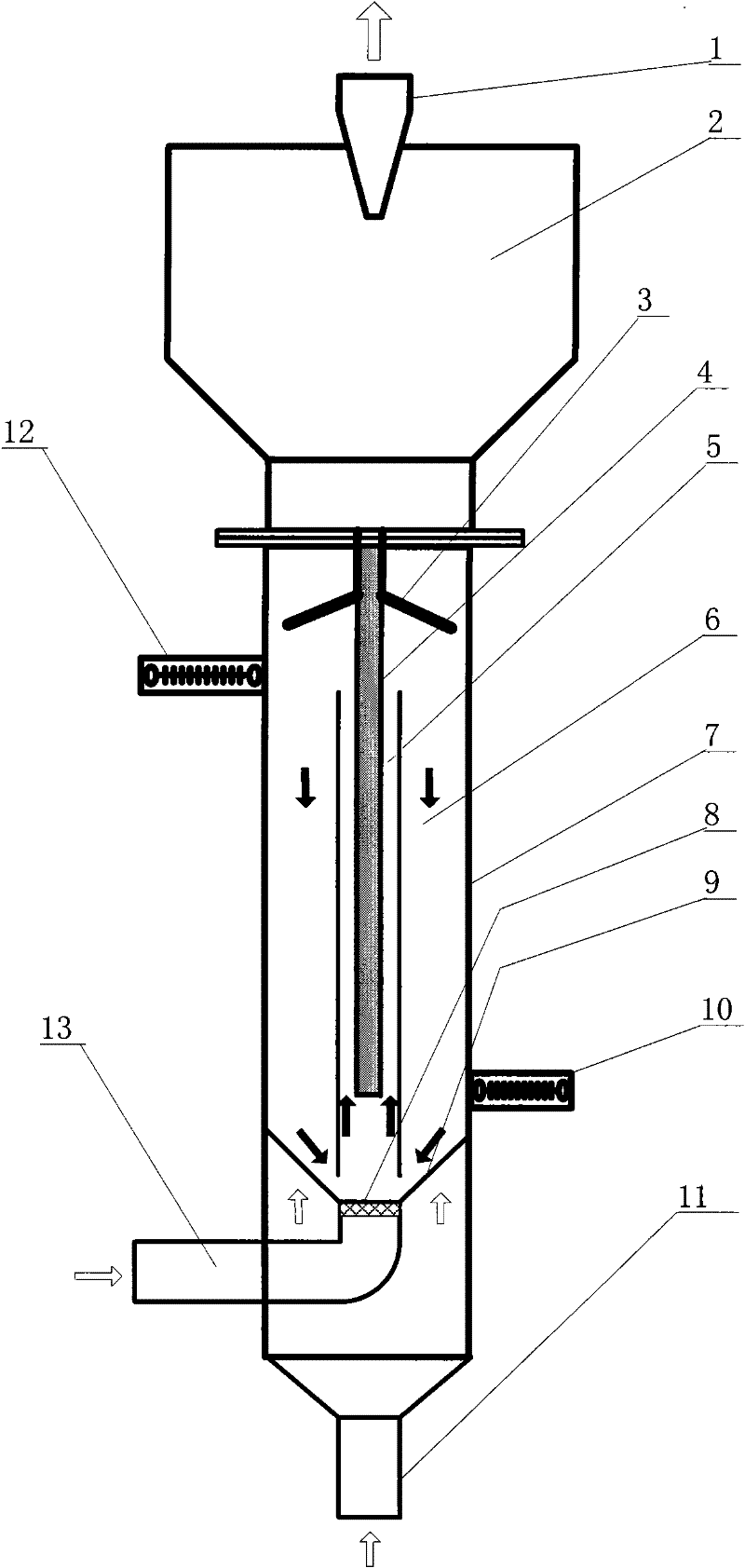

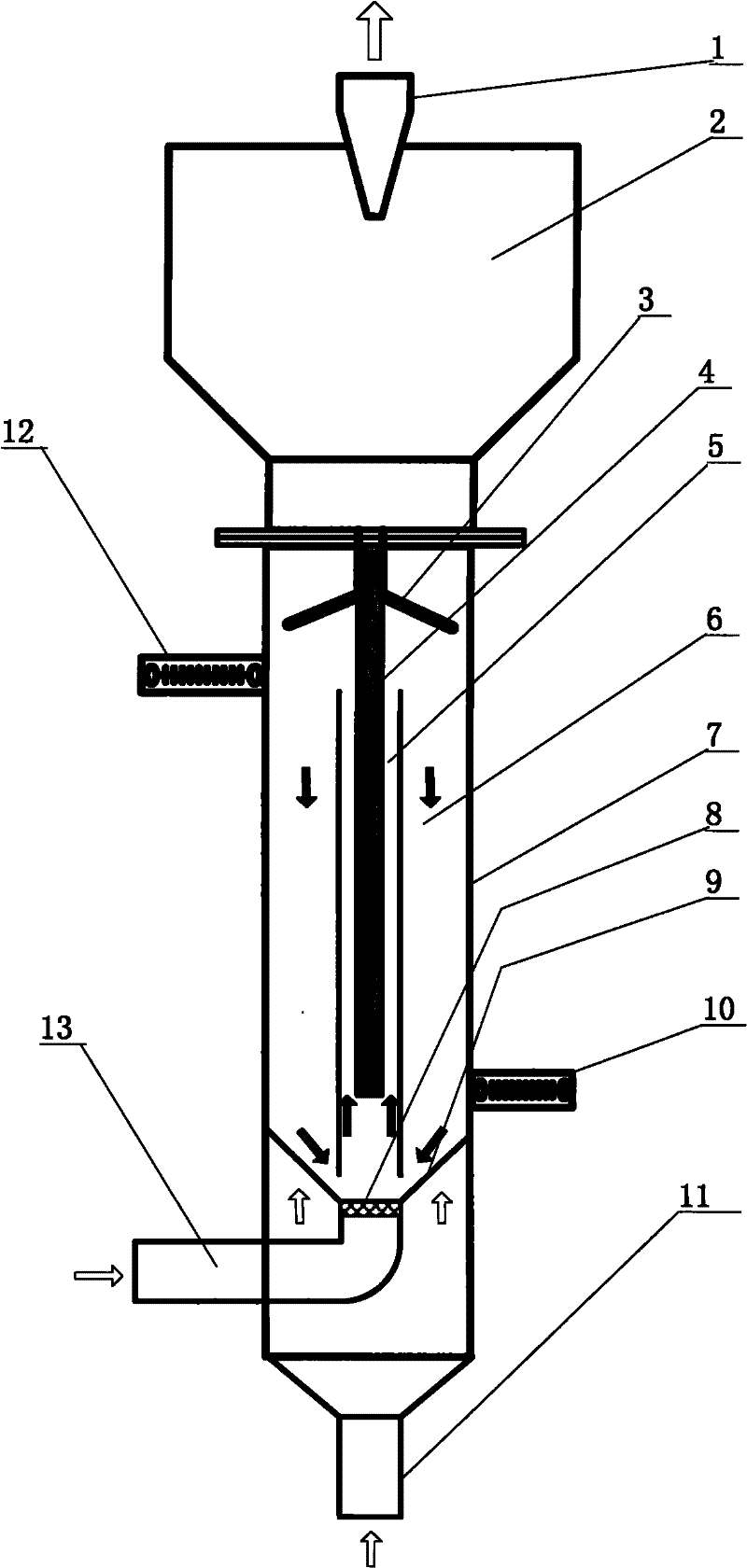

Spouted bed reactor and method thereof for synthesizing chlorinated polyvinyl chloride by using low-temperature plasmas

A low-temperature plasma and chlorinated polyvinyl chloride technology, applied in the field of synthetic chlorinated polyvinyl chloride methods and reactors, to achieve the effects of less pollution, improved product quality, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The reactor was operated at atmospheric pressure. PVC particles with an average particle size of 250 μm are loaded into the reactor at the polyvinyl chloride raw material feed port 12, and the feed mass is 5 g. The input power of the low temperature plasma power supply is 50W. The reaction temperature was 100°C. Argon is used as the loosening gas, which is introduced from the loosening gas inlet 11, and the PVC particles deposited on the bottom of the reactor are dispersed under the action of the loosening gas; pure chlorine gas is input from the raw material gas inlet 13, and the PVC particles are entrained at a relatively high flow rate and pass through quickly Low-temperature plasma reaction zone 5 activates chlorine gas and PVC particles, and chlorination reaction occurs, and the residence time is 60s. The chlorinated polyvinyl chloride particles obtained by the reaction and the unreacted polyvinyl chloride particles go up to the particle downstream baffle plate 3...

Embodiment 2

[0038] The reactor was operated at atmospheric pressure. PVC particles with an average particle size of 150 μm are loaded into the reactor at the polyvinyl chloride raw material feed port 12, and the feed mass is 5 g. The input power of the low temperature plasma power supply is 50W. The reaction temperature was 100°C. Using argon as the loosening gas, it is introduced from the loosening gas inlet 11, and the PVC particles deposited on the bottom of the reactor are dispersed under the action of the loosening gas; the mixed gas of chlorine and argon is input from the raw material gas inlet 13, and the chlorine gas fraction is 80%. Entrained PVC particles pass through the low-temperature plasma reaction zone 5 quickly at a relatively high flow rate, activating chlorine gas and PVC particles, and chlorination reaction occurs, and the residence time is 60s. The PVC granules go up to the baffle plate 3, and flow back to the chlorine migration area 6 under the action of the baffle...

Embodiment 3

[0041] The reactor was operated at atmospheric pressure. PVC particles with an average particle size of 50 μm are loaded into the reactor at the polyvinyl chloride raw material feed port 12, and the feed mass is 5 g. The input power of the low temperature plasma power supply is 100W. The reaction temperature was 60°C. Argon is used as the loosening gas, which is introduced from the loosening gas inlet 11, and the PVC particles deposited at the bottom of the reactor are dispersed under the action of the loosening gas; pure chlorine gas is input from the raw material gas inlet 1 3, and the PVC particles are entrained at a relatively high flow rate to move up quickly Through the low-temperature plasma reaction zone 5, chlorine gas and PVC particles are activated, and a chlorination reaction occurs, and the residence time is 10s. The PVC granules go up to the baffle plate 3, and flow back to the chlorine migration area 6 under the action of the baffle. The mixed gas of argon go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com