Method for repairing solar cell module

A technology of solar cells and modules, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as cell fragmentation and affecting power generation, achieve accurate repair, ensure quality and performance, and reduce hidden cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

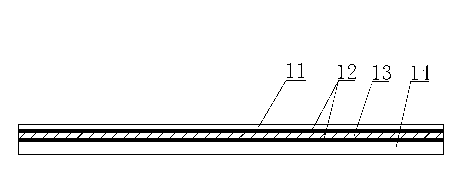

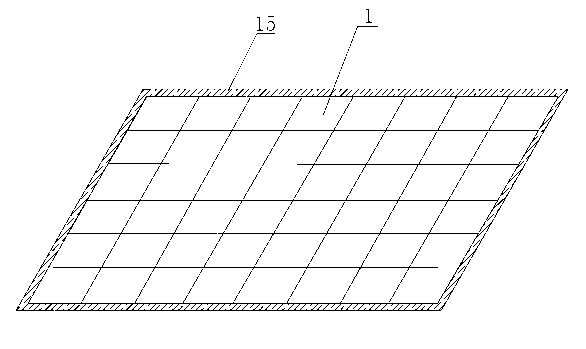

[0029] Such as figure 1 and 2 As shown, the solar cell module is formed by bonding glass, battery sheet and back plate together at high temperature through EVA, and bonding a frame around it.

[0030] A method for repairing solar cell components in the present invention mainly involves repairing the laminated components, including the following workflow:

[0031] 1) Remove the component frame. For components that need to be repaired after disassembly, the unframer shall wipe off the silicone on the components.

[0032] 2) Put the reworked components on the reworked heating table, be careful when handling, avoid bumping the components, and clean the foreign matter on the surface of the components, and then close the cover of the reworked heating table.

[0033] 3) Set the process parameters of the rework heating table, the heating time is 120-180s, and the heating temperature is 150-180°C.

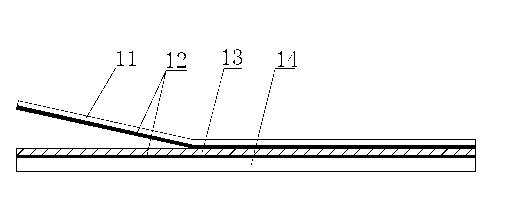

[0034] 4) if image 3 As shown, peel off the back panel. After the heating is ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com