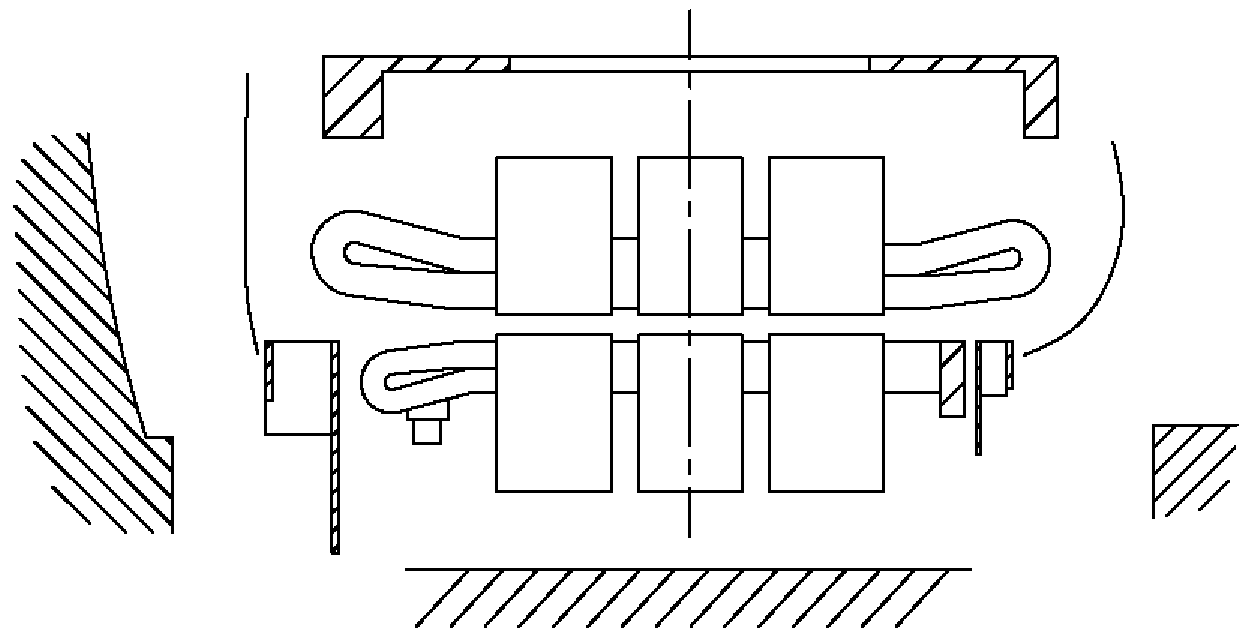

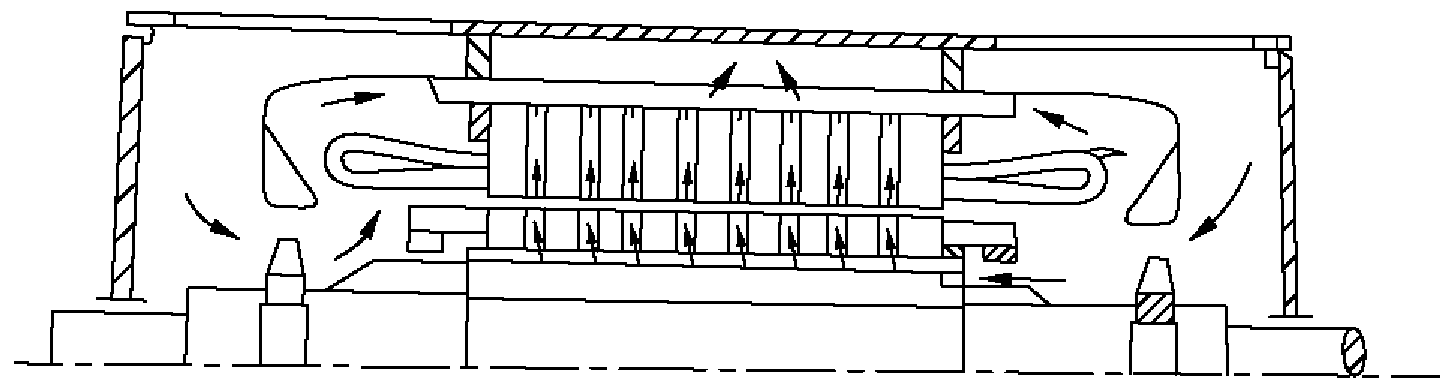

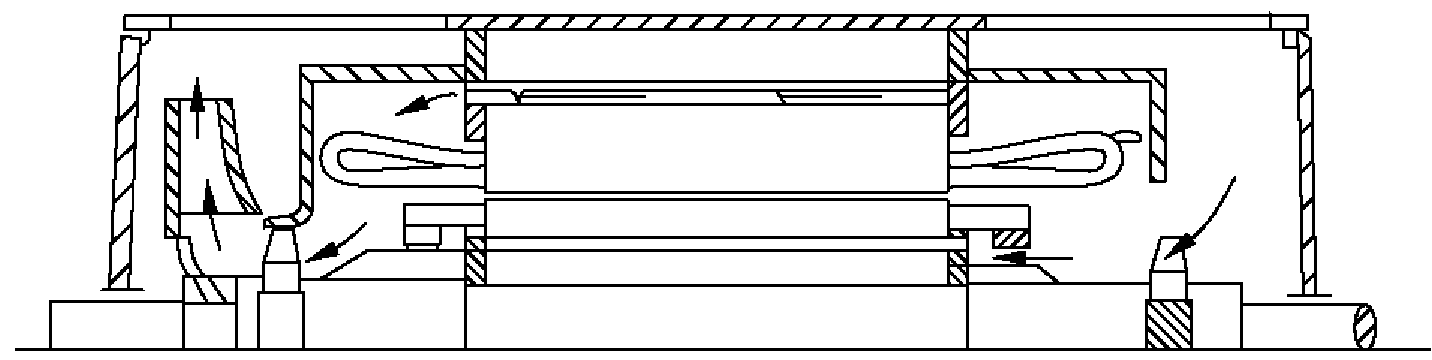

Overall machine wind path structure of high-power and high-peed permanent magnet synchronous motor

A permanent magnet synchronous motor, high-power technology, applied in the shape/style/structure of the magnetic circuit, rotating parts of the magnetic circuit, electrical components, etc. and other problems to achieve the effect of strengthening the cooling effect, enhancing the cooling effect, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the air passage structure of the whole machine of the high-power and high-speed permanent magnet synchronous motor of the present invention is given below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to the following embodiments.

[0036] see Figure 5 . The wind path structure of the high-power high-speed permanent magnet synchronous motor includes a motor 20 and a cooler 1 that cooperate with each other. The motor 20 includes a stator 21 and a rotor 22. The stator 21 surrounds the rotor 22 with an air Gap 23. The rotor 22 comprises a rotor shaft 7 and a rotor pole 9 . The rotor pole 9 includes a permanent magnet 4 and a magnetic pole 5 . The stator 21 is provided with a radial ventilation channel 10 formed by the stator radial ventilation groove plate 8; the rotor 22 adopts a welded rib shaft structure, and the space between the welded ribs forms a waist-shaped ventilati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com