Piston engine drivable using a steam power process

A technology of piston engine and piston, which is applied in the direction of steam engine device, internal combustion piston engine, reciprocating piston engine, etc., and can solve the problems of narrow structural space of internal combustion engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

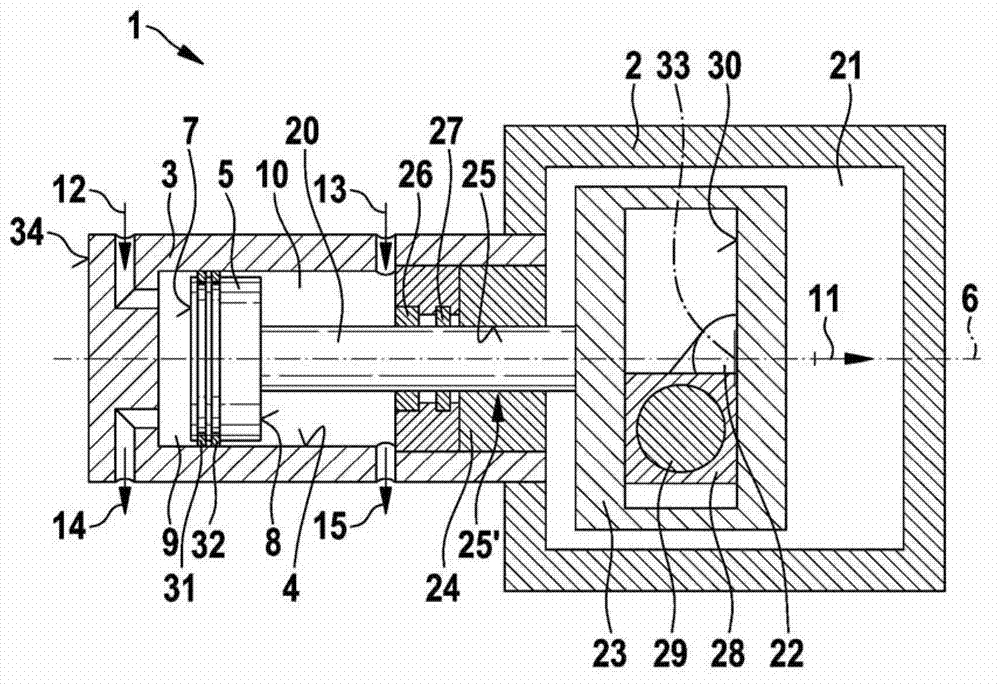

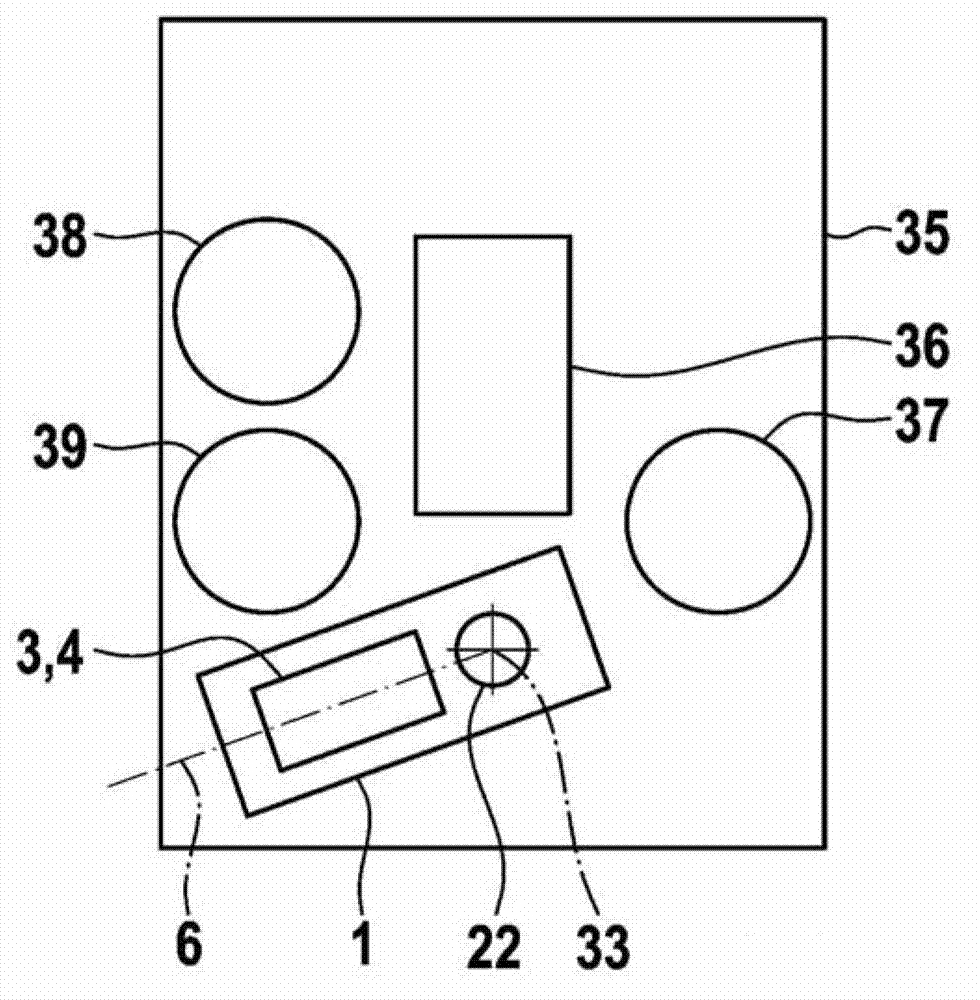

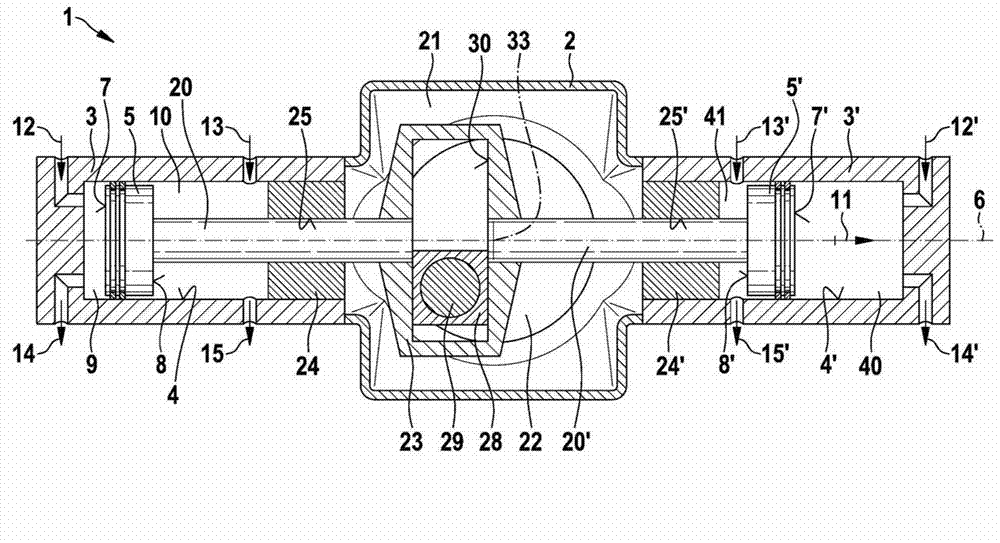

[0032] figure 1 A piston machine 1 according to a first exemplary embodiment of the invention is shown schematically. The piston machine 1 is driven by a steam process. The piston machine 1 can be used here in particular in an internal combustion engine of a motor vehicle in order to utilize the waste heat of the internal combustion engine. The piston machine 1 then converts the waste heat into mechanical energy, which can be used, for example, as additional drive energy or to drive auxiliary units, in particular a generator. However, the piston machine 1 according to the invention is also suitable for other applications.

[0033] The piston machine 1 has a housing part 2 and a cylinder 3 connected to the housing part 2 . In this exemplary embodiment, the piston machine 1 has exactly one cylinder 3 .

[0034] The cylinder 3 of the piston machine 1 has a cylinder bore 4 in which a cylinder piston 5 is arranged. The cylinder piston 5 is here displaceably arranged in the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com