Inflatable cabinet sealing automatic welding positioning device

An automatic welding and positioning device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low work efficiency, long positioning and pressing time, and difficult loading, so as to reduce production costs and improve production efficiency. , The effect of positioning and locking is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

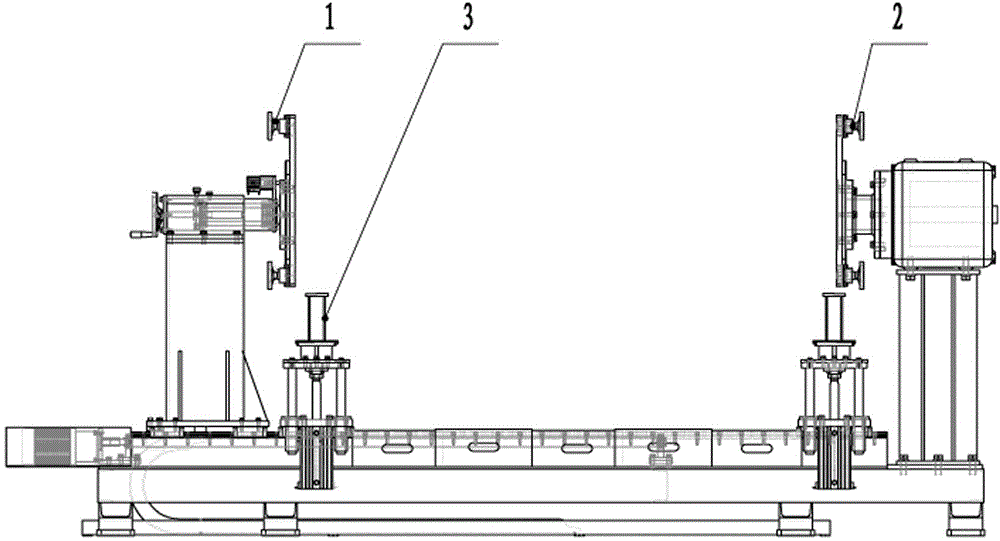

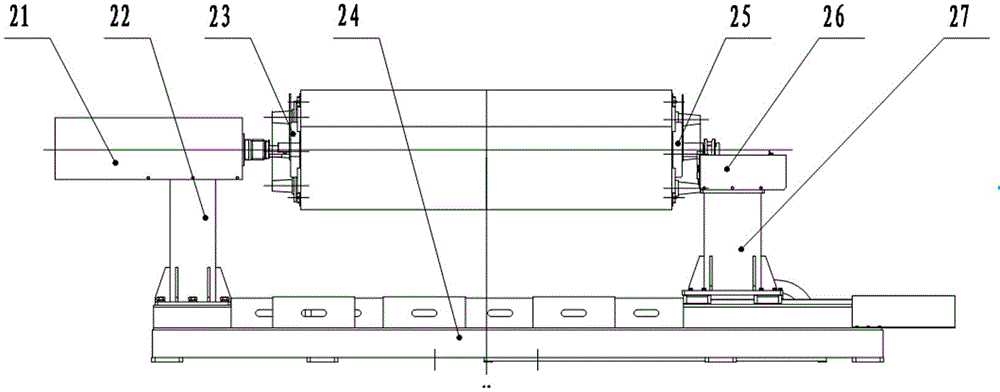

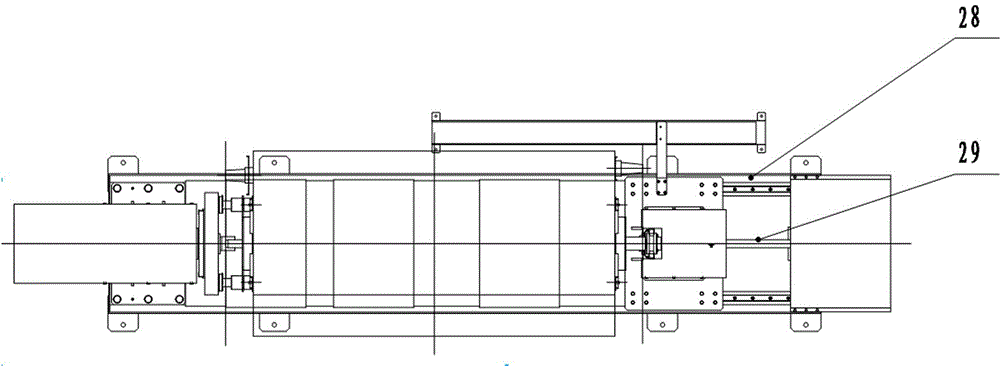

[0032] As shown in the figure, the sealed automatic welding positioning device of the inflatable cabinet includes a base assembly, a positioner assembly 21, a main turntable 23, an auxiliary turntable 25, and a support shaft assembly 26, and the feature is that the positioner assembly 21 and the support shaft assembly 26 pass through The bolts are fastened together with the base assembly 24; the V-shaped grooves on both sides of the main turntable 23 fall onto the positioning taper pins on both sides of the torsion positioning arm of the positioner assembly 21; the bearing roller assembly on the auxiliary turntable 25 Fall into the positioning V-shaped groove of the supporting shaft assembly 21; the supporting shaft assembly 26 at the tail acts as a clamping cylinder, and uses the linear guide rail to push the entire workpiece to the side of the positioner assembly, and twist the two sides of the positioning arm The positioning taper pin cooperates with the V-shaped grooves on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com