Multi-nut fixed torque mounting device

A mounting device and torque-fixing technology, which is applied to screwdrivers, wrenches, wrenches, etc., can solve the problems of time-consuming, labor-intensive work, low work efficiency, and heavy labor load of workers, and achieve simplified fastening procedures, convenient operation and maintenance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

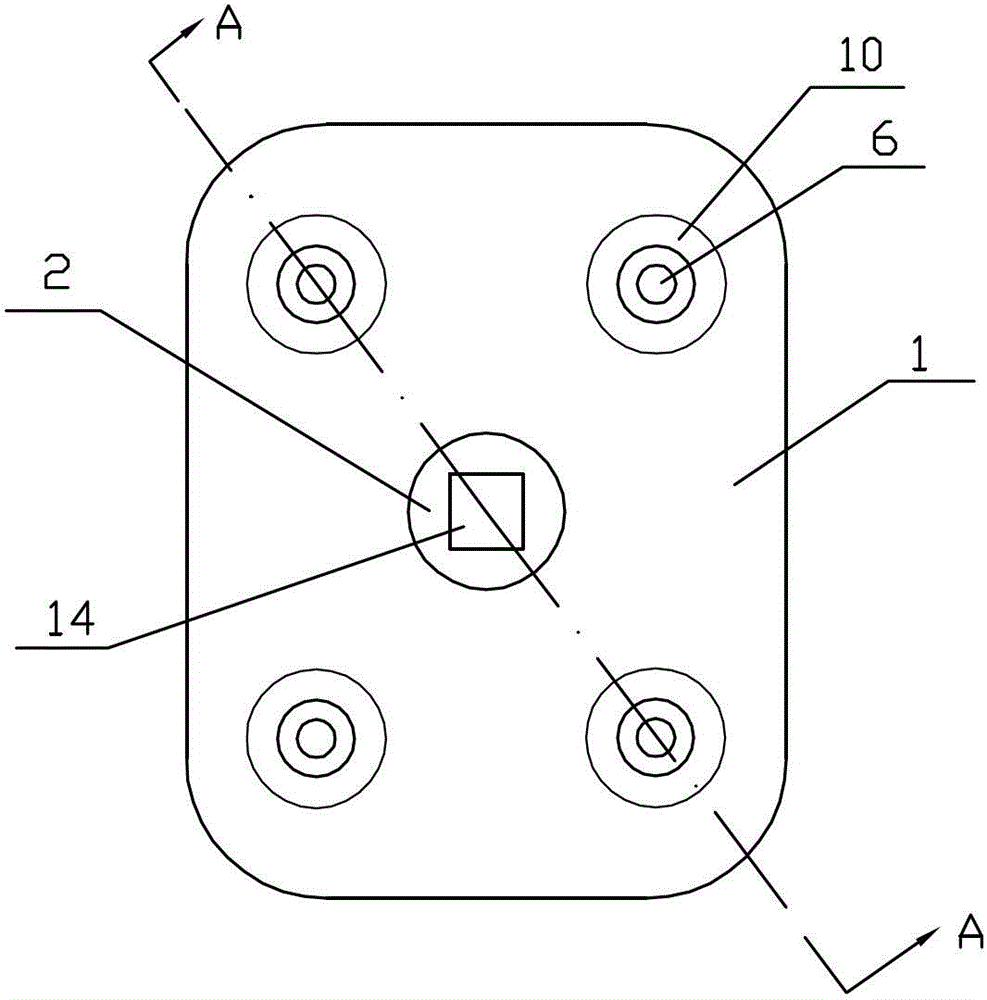

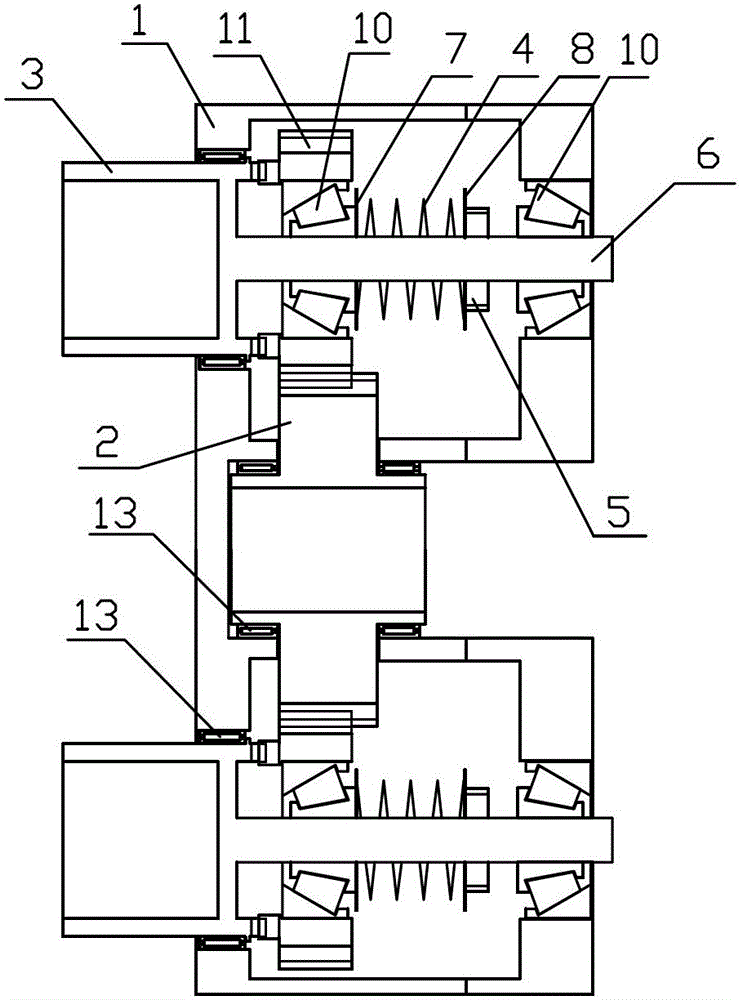

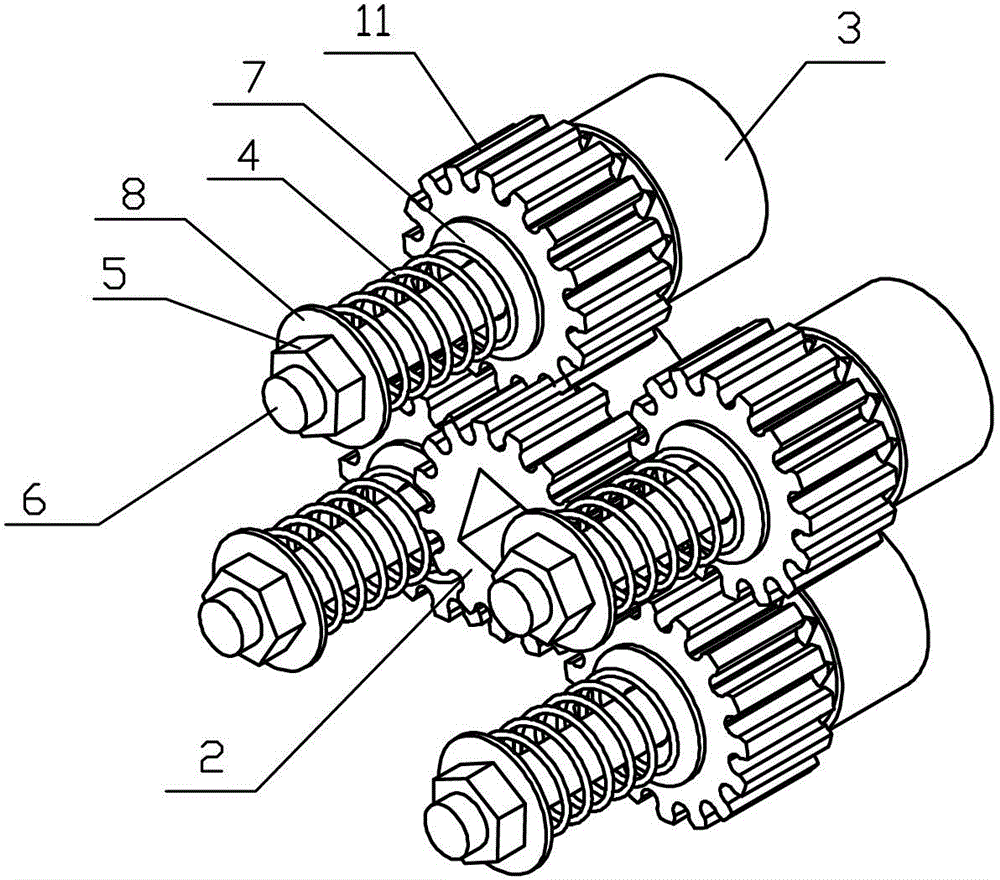

[0020] Embodiment 1: the multi-nut fixed torque mounting device of the present embodiment, such as figure 1 As shown, it includes a housing 1 formed by fastening the lower bottom and the upper cover, a coupling sleeve 2 and four nut sleeves 3 installed on the housing, the coupling sleeve is located in the center of the housing, and the four nut sleeves The barrels are located at the four corners of the housing. The nut sleeve 3 is connected with the housing through a cylindrical needle bearing 13 . The center of coupling sleeve 2 has a square counterbore 14, as figure 2 As shown, the opening direction of the square counterbore 14 is opposite to the opening direction of the nut sleeve 3, and the middle part of the outer circumference of the coupling sleeve 2 is a ring of gears, and a cylindrical needle bearing 13 is installed on each side of the gear, and the coupling sleeve 2 passes through The two cylindrical needle bearings 13 are connected to the housing 1 . The front e...

Embodiment 2

[0022] Embodiment 2: In the multi-nut constant torque installation device of this embodiment, four torque adjustment ports are opened on the outer surface of the housing 1 , and the positions of the torque adjustment ports correspond to the positions of the adjustment nuts 5 . The torque adjustment port can accommodate a wrench to extend into the housing 1, and the adjustment nut 5 is turned by the wrench to complete the torque setting. All the other structures are with embodiment 1. The setting and adjustment of the torque in this embodiment are more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com