Movable in-row template

A template and limiting plate technology, which is applied in molds, ceramic molding machines, manufacturing tools, etc., can solve the problems of high production cost, complex system structure, and high requirements for site conditions, and meet the requirements of low production cost, small size, and production site conditions low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

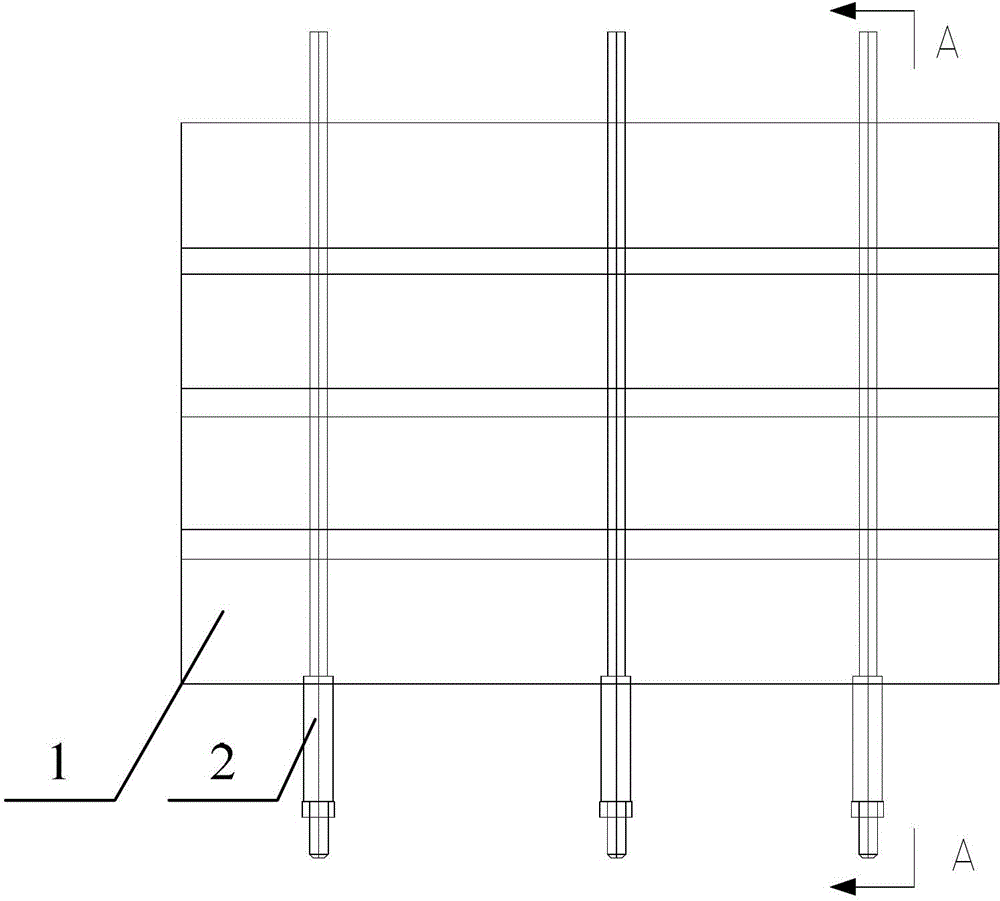

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 and Figure 5 , the movable formwork of the present invention includes U-shaped steel molds 1 and fasteners 2, and a plurality of U-shaped steel molds 1 are welded end to end to form a unit mold, and four groups of said unit molds are connected by three said fastening elements. Pieces 2 are connected side by side. The fasteners 2 adjust the fastening amount by tightening the nuts 204 when the template is fastened, and the three fasteners 2 are arranged in parallel; the fasteners 2 include a lead screw 202, a limit plate 201 , a movable limiting plate 203 and a nut 204, the limiting plate 201 is fixedly connected with one end of the lead screw 202, the movable limiting plate 203 is connected with the other end of the leading screw 202 with clearance fit, the A screw pair is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com