Riding wheel device for belt conveyor

A technology of belt conveyor and supporting roller, which is applied in the field of machinery manufacturing and processing, can solve the problems of easy damage, etc., and achieve the effect of convenient refueling, not easy to damage, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

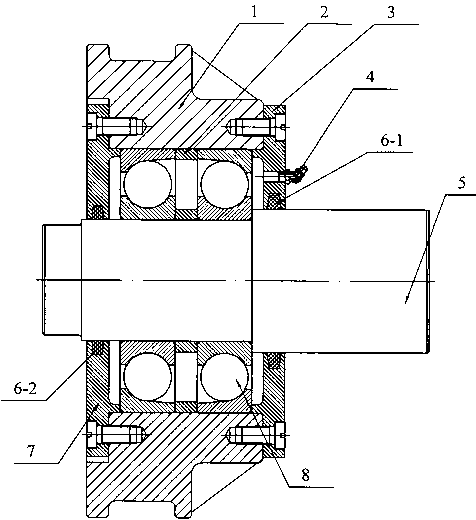

[0019] Such as figure 1 As shown, an idler device for a belt conveyor includes: a roller body 1 , a cover plate A3 , a cover plate B7 , a shaft 5 and a bearing 8 , and a retaining ring 2 is also included. Wherein: the shaft 5 is connected to the inner ring of the roller body 1 through the bearing 8, and the cover plate A3 and the cover plate B7 are respectively set on both ends of the shaft 5 and fixedly connected to the outer side of the roller body 1.

[0020] The above solution effectively prevents external impurities from entering the inner ring of the roller body, and improves the service life of the supporting roller device for the belt conveyor.

[0021] In fact, in order to effectively prevent the end jump of the shaft, the supporting roller device used for the belt conveyor runs stably. The bearing 8 is preferably two single-row radial thrust ball bearings, and the two single-row radial thrust ball bearings are connected by a retaining ring 2 .

[0022] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com