Protective paint for retarding or preventing migration of conductive silver ions, preparation method and application thereof

A technology of protective coatings and ion migration, applied in polyester coatings, coatings, etc., can solve problems such as inability to answer affirmatively, achieve excellent barrier effect, improve the degree of compactness, and achieve the effect of good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

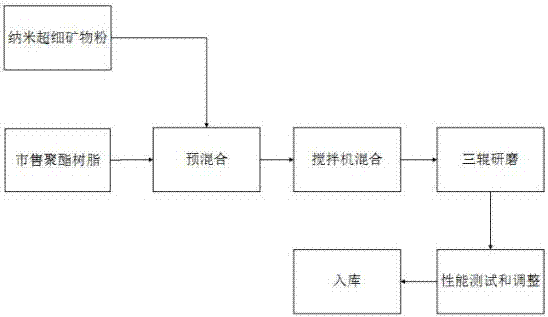

Method used

Image

Examples

Embodiment 1

[0034] HF-18483# polyester resin solution (solid content 50%, viscosity 1000-2000 centipoise); wet-process sericite powder, particle size ≤ 3 μm; solvent is DBE (dibasic acid ester mixture). Mixture composition ratio (weight ratio): 85.0 parts of polyester resin solution, 12.0 parts of wet-process sericite powder, and 3.0 parts of solvent.

[0035] Put the above-mentioned weighed components (total weight 1000.0 grams) in the 5L plastic tank equipped with the EA-ST208B ink mixer, first mix them by hand stirring, and then put the plastic tank in the ink mixer On the fixed seat, stir at a speed of 100rpm for 30 minutes to fully mix, take out the mixture and put it into a laboratory three-roller grinder to grind it twice, put the mixture in a special container, and place it at 25°C for 24 hours for later use.

Embodiment 2

[0037] HF-18483# polyester resin solution (solid content 50%, viscosity 1000-2000 centipoise); wet-process sericite powder, particle size ≤ 3 μm; ultra-fine graphite powder, particle size ≤ 0.5 μm, carbon content 99.99%; The solvent is DBE (dibasic acid ester mixture). Mixture composition ratio (weight ratio): 82.0 parts of polyester resin solution, 8.0 parts of wet-process sericite powder, 5.0 parts of ultrafine graphite powder, and 5.0 parts of solvent.

[0038] Put the above-mentioned weighed components (total weight 1000.0 grams) in the 5L plastic tank equipped with the EA-ST208B ink mixer, first mix them by hand stirring, and then put the plastic tank in the ink mixer On the fixed seat, stir at a speed of 100rpm for 60 minutes to fully mix, take out the mixture and put it into a laboratory three-roller grinder to grind it twice, put the mixture in a special container, and place it at 25°C for 24 hours for later use.

[0039] The manufacturability indexes of the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com