Seabed oil storage system

An oil storage system and oil storage tank technology, applied in water conservancy projects, artificial islands, caissons, etc., can solve problems such as large waves, ocean currents, tides, structural cost increases, and high costs, so as to shorten the operation period and reduce the length. , the effect of reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

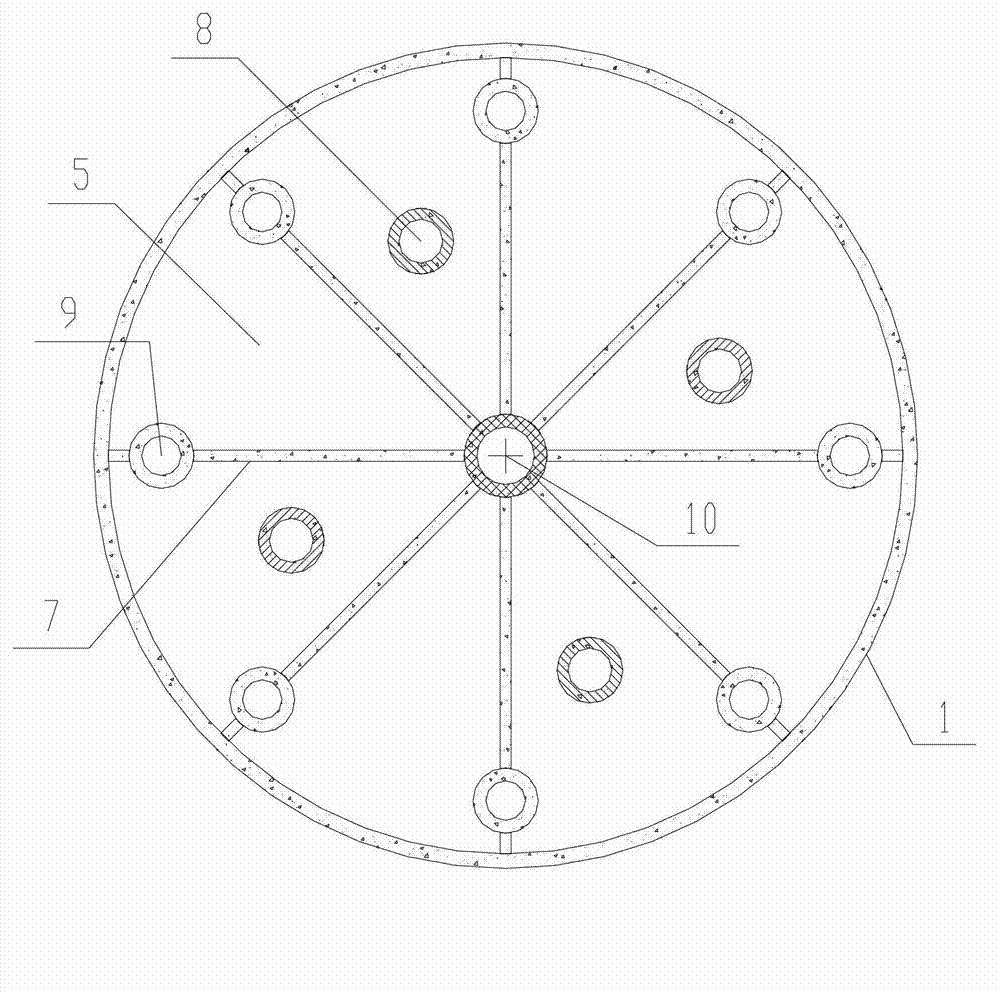

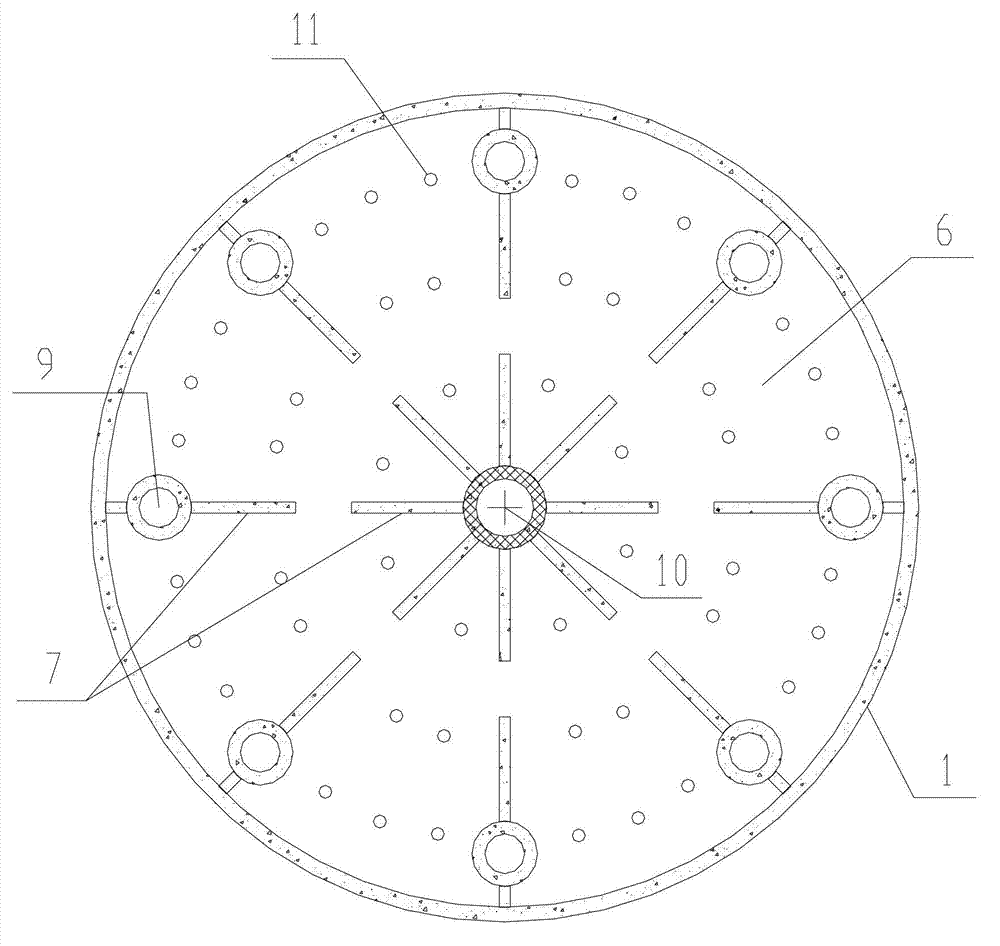

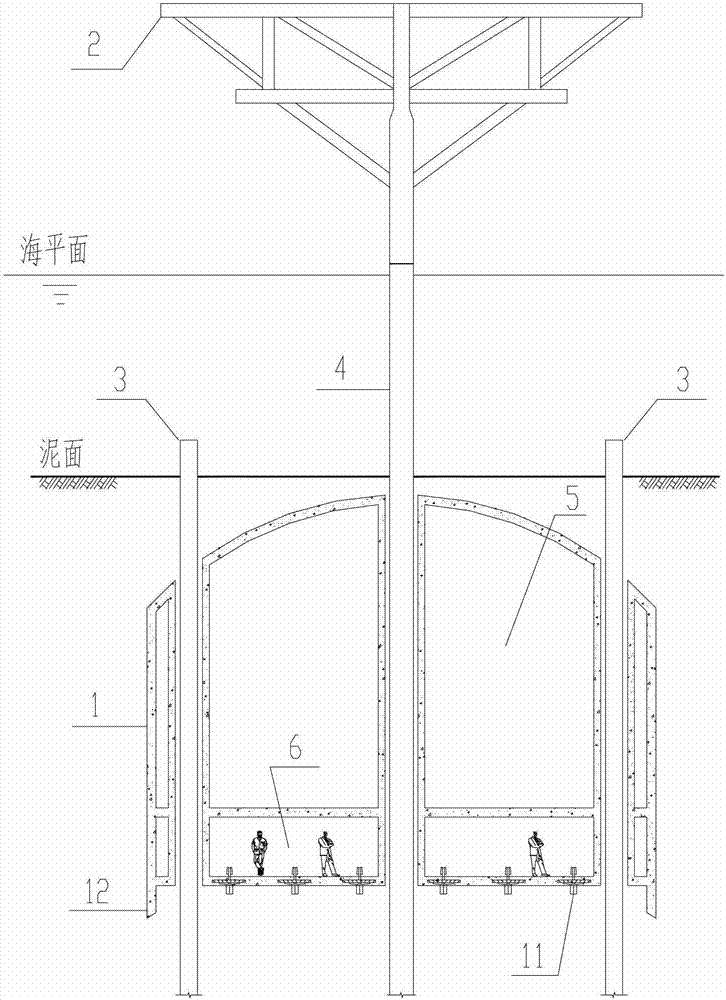

[0038] Such as Figure 1-Figure 4As shown, the subsea oil storage system of the present invention includes a subsea oil storage tank 1 and a simple platform 2, and a positioning steel pile 4 is fixed in the central axial direction of the subsea oil storage tank 1, and the two ends of the positioning steel pile 4 extend to the seabed In addition to the oil storage tank 1, one end of the positioning steel pile 4 is connected to the simple platform 2; The basic component is also used as the fixing and positioning component of the subsea oil storage tank 1 during the construction of the caisson, so as to ensure that the subsea oil storage tank 1 is always in a straight state during the construction of the caisson, so as to avoid its inclination and water flow during the construction of the caisson. Dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com