Directional hydraulic fracturing connected mining method

A technology of hydraulic fracturing and mining method, which is applied in the direction of mining fluid, earth drilling, wellbore/well components, etc., which can solve problems such as low resource recovery rate, disorderly arrangement, and collapse of the roof of the dissolved cavity, so as to improve safety, Avoid vertical cracks and eliminate the effect of ground brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

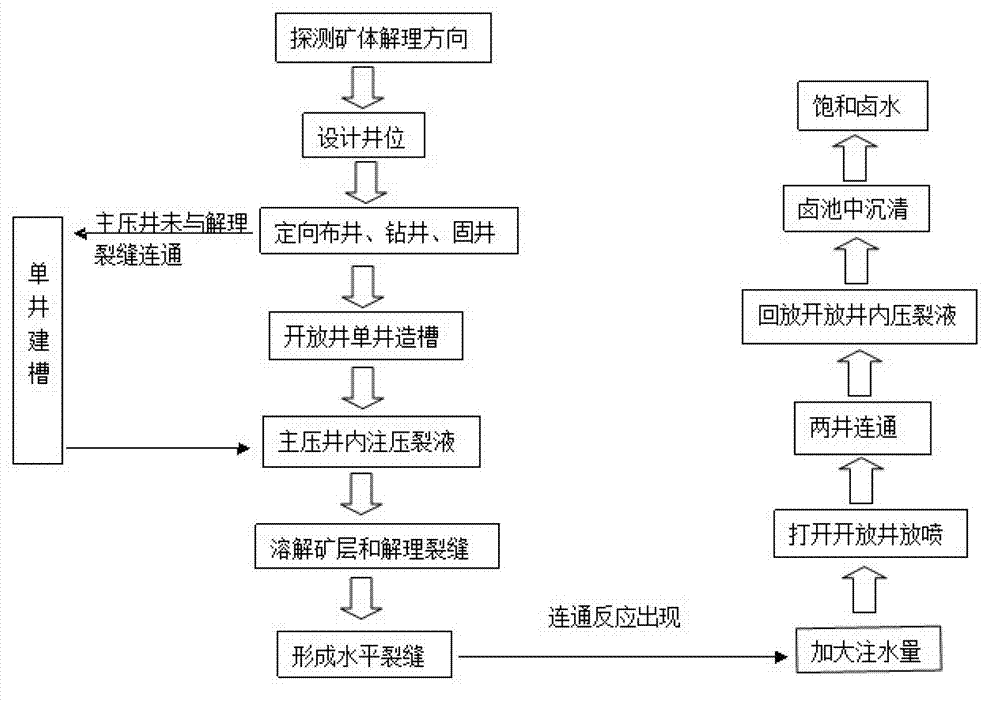

[0027] A method for directional hydraulic fracturing connected production, comprising the following steps: directional well arrangement, fracturing connected, and continuous production;

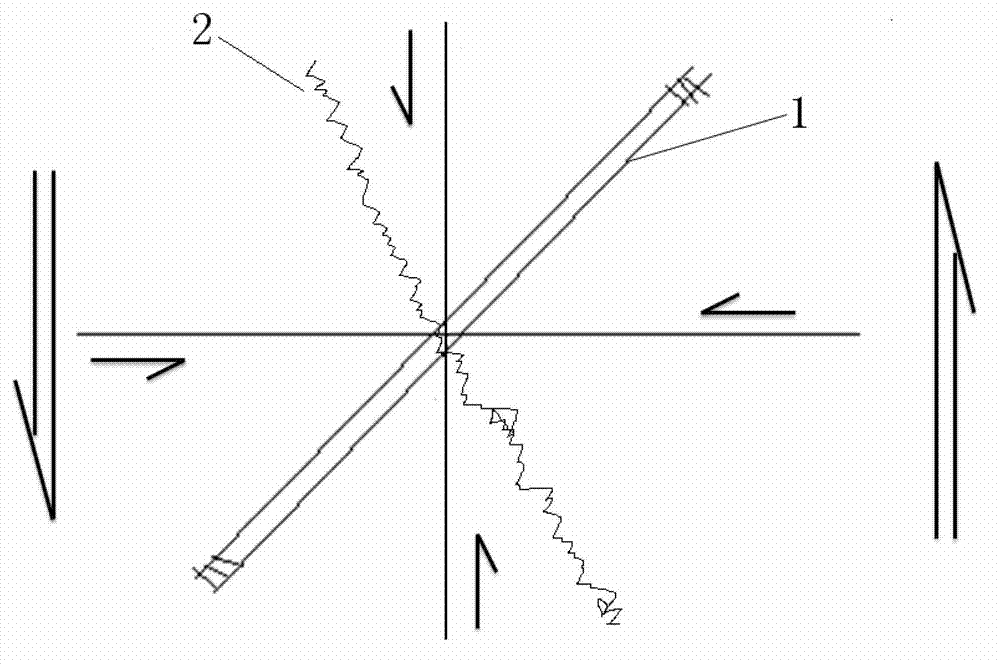

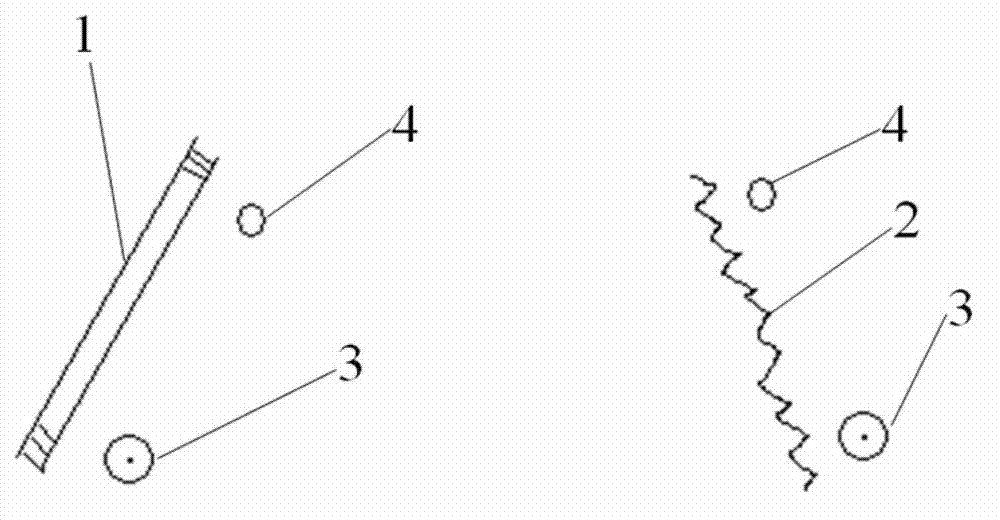

[0028] The directional well layout: detect the natural cleavage fracture direction of the ore body, design and arrange the fracturing well group along the cleavage direction, and the bottom of the main pressure well is slightly lower than the bottom of the open well, implement drilling, well cementing, and hole sweeping ,Pressure test.

[0029] The fracturing is connected: the open well is constructed with a single well before the fracturing operation to form a low stress release zone, the bottom hole dissolution cavity of the main well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com