An electronically controlled shift controller for a loader gearbox

A technology of loader and gearbox, applied in transmission control, mechanical equipment, components with teeth, etc., can solve the problems of controller burning, complicated shifting mechanism, and high labor intensity of drivers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

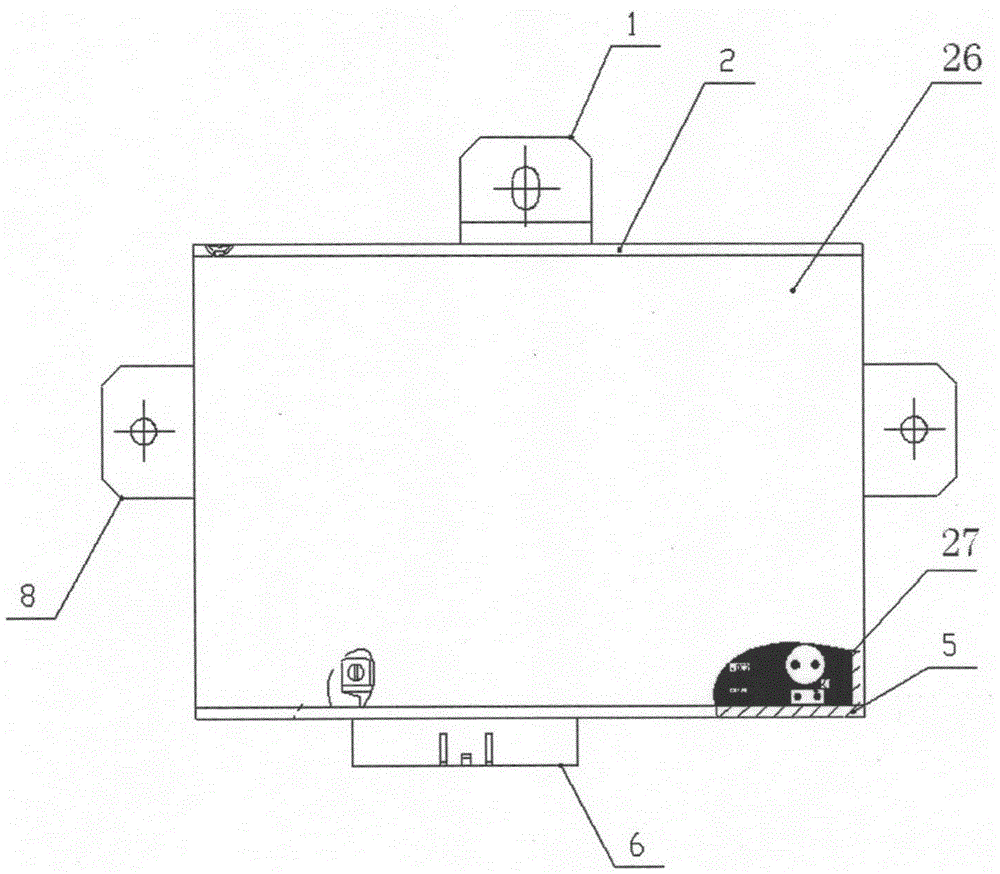

[0092] Such as figure 1 As shown, the present invention provides an electronically controlled shift controller for a loader gearbox, which includes a housing 26, a circuit unit 27 is arranged in the housing 26, and a mounting plate 1 and a mounting plate 8 are arranged on the housing 26. The casing 26 has a rear cover 2 and a front cover 5 . Wherein the mounting plate 1 and the mounting plate 8 are fixed by triangle irons, and the whole is simple and elegant. The back cover 2, the front cover 5 and the housing 26 are waterproofed, and the plug-in itself has excellent waterproof performance and is easy to insert and remove.

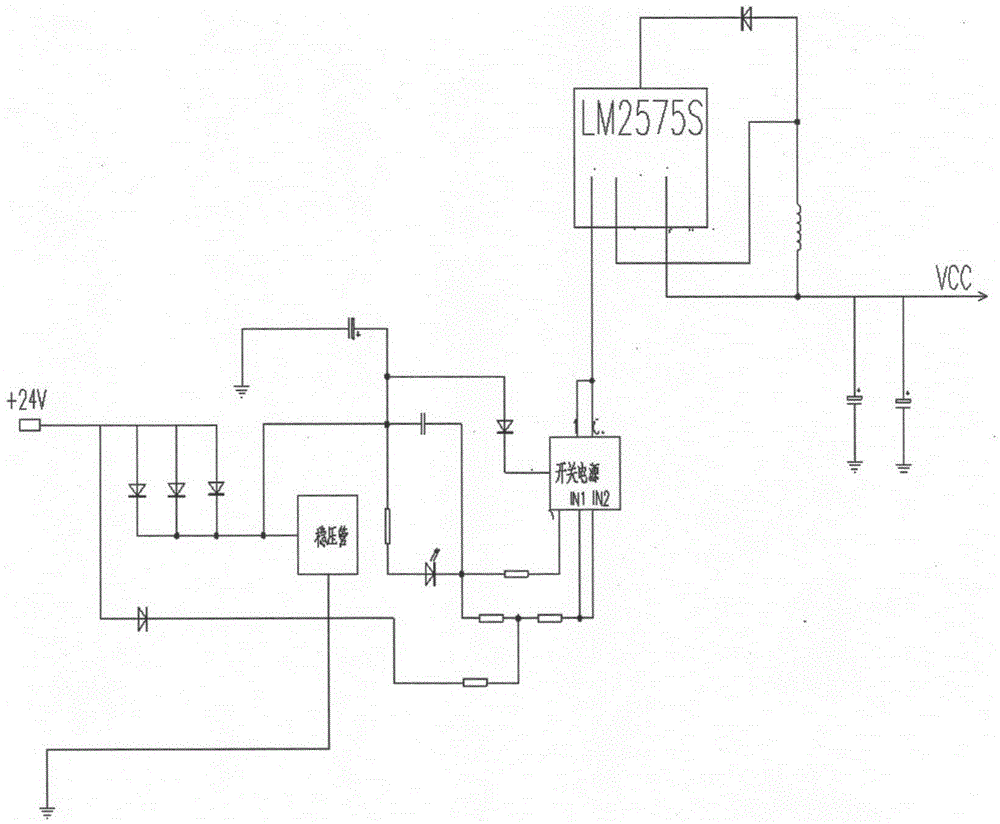

[0093] The circuit unit 27 includes a logic control module and a power supply module that provides a DC voltage VCC for the logic control module, wherein:

[0094] Such as figure 2As shown, the power modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com