Platinum resistance temperature sensor with high intensity and fast response

A temperature sensor, platinum resistance technology, used in thermometers, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve the problem that the thermometer cannot meet the thermal response time, etc., and achieve long service life, high precision, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

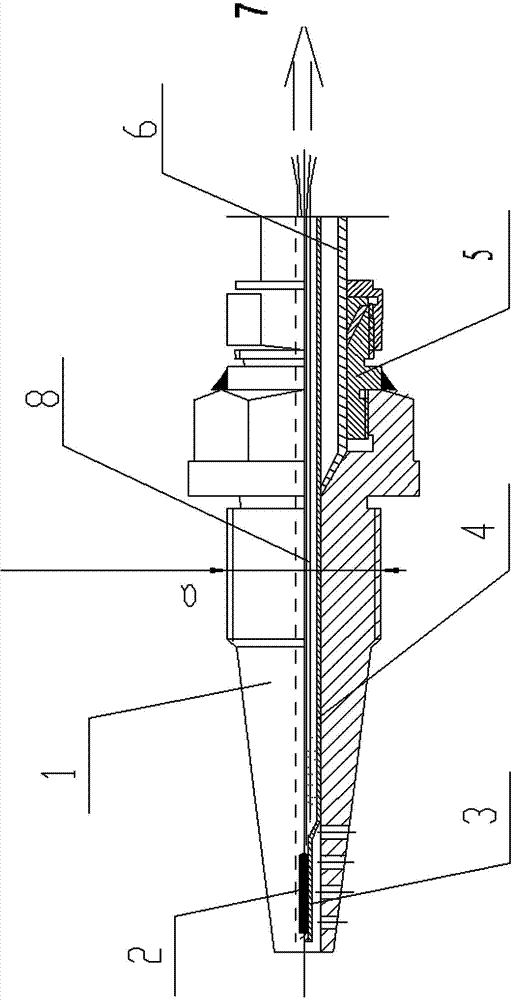

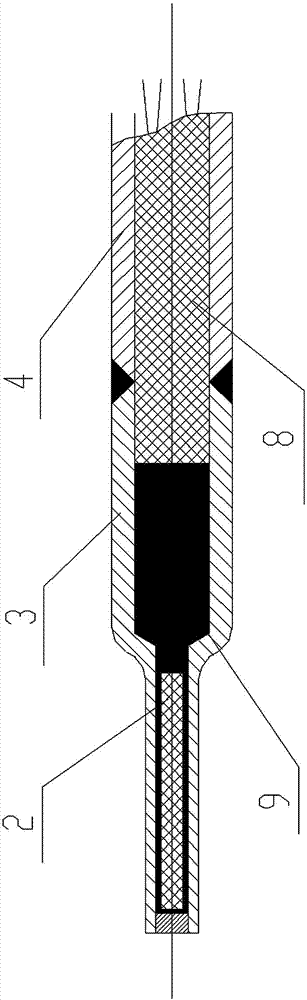

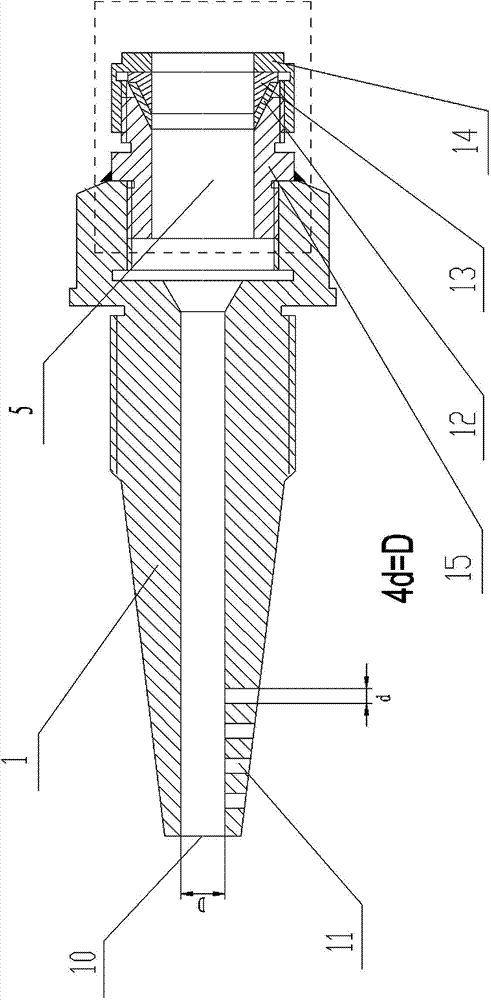

[0029] see Figure 1-Figure 4 . High-strength, fast-response platinum resistance temperature sensor, including temperature-sensing element, temperature-sensing sleeve, inner protection tube and outer protection tube. The temperature-sensing element 2 is installed in the small-diameter section of the variable-diameter temperature-sensing sleeve 3, and the wall thickness at the small-diameter part is as thin as possible while ensuring the strength, so as to improve the heat conduction capability and reduce the thermal response time of the thermometer. The gap between the temperature sensing element and the temperature sensing sleeve is filled with insulating material 9, the insulating material is MgO or Al 2 o 3 Or BeO, the insulating material between the temperature sensing element and the temperature sensing sleeve should be as dense as possible to improve the thermal conductivity and reduce the thermal response time of the thermometer. In this embodiment, the temperature-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com