Exposure machine alignment method and control equipment

A technology for controlling equipment and exposure machines, which is applied to microlithography exposure equipment, originals for photomechanical processing, and exposure devices for photographic plate-making processes. It can solve the problems of reduced production efficiency, low focus definition, and equipment utilization and other problems to achieve the effect of improving the success rate of alignment, improving production efficiency, and avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

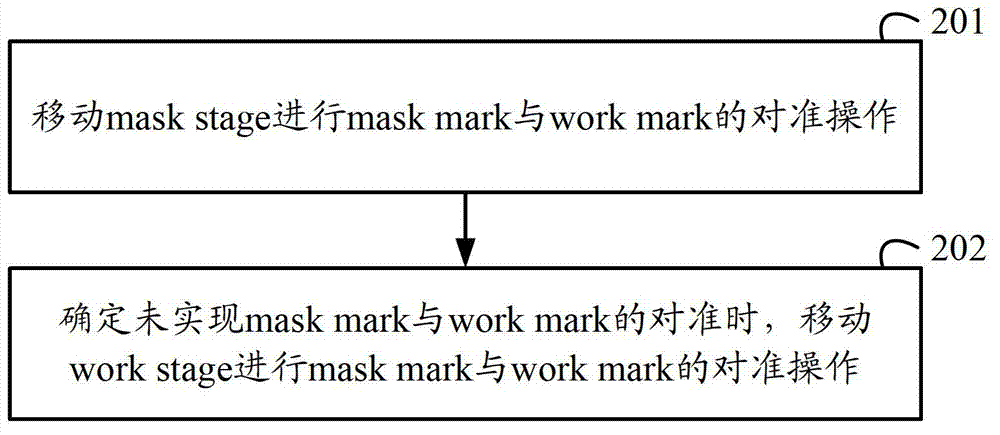

[0024] In order to avoid the misalignment caused by the traditional operation of only moving the abutment carrying the mask to perform alignment mark alignment, improve the success rate of alignment, and improve production efficiency, an embodiment of the present invention provides an exposure machine Counterpoint method.

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

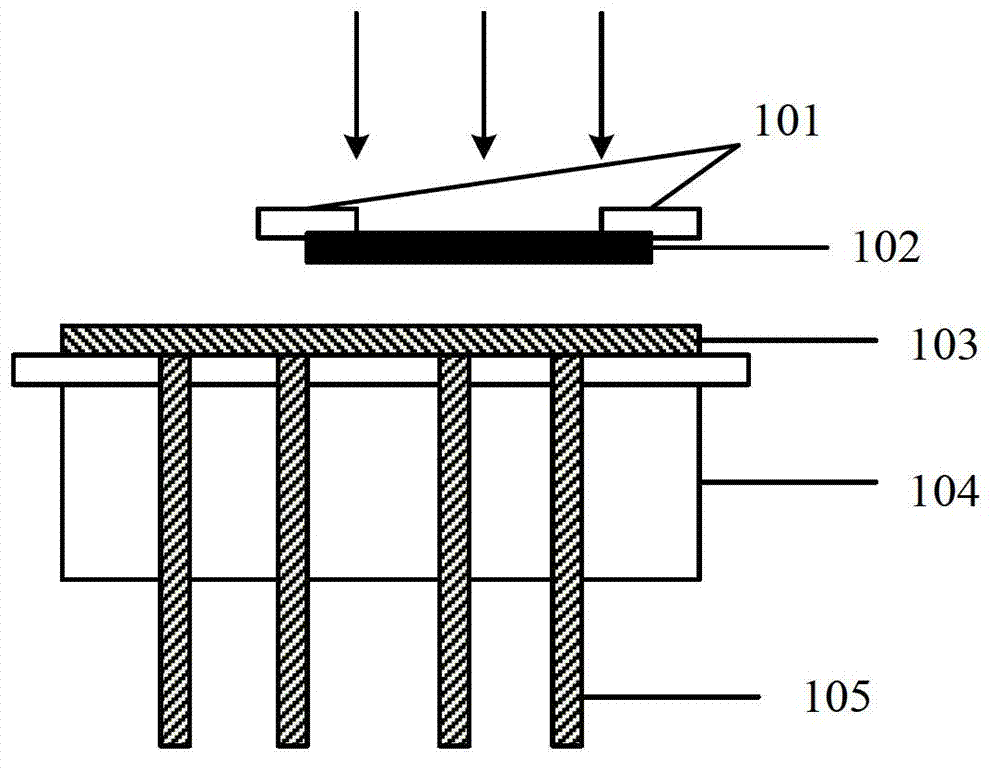

[0026] as attached figure 1 Shown is a schematic diagram of a cross-sectional structure for exposing a substrate, which includes a base (mask stage) 101 for carrying a mask (mask) 102, the mask 102 is adsorbed on the lower surface of the mask stage 101 by vacuum adsorption, and includes a carrying The abutment (work stage) 104 of the substrate (Glass) 103, the Glass 103 is placed on the upper surface of the work stage 104, and also includes a support foot (work pin) 105 for supporting the Glass 103, and the support foot 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com