Transparent conductive film

A technology of transparent conductivity and transparent conductor, applied in the direction of conductive layer, circuit, printed circuit, etc. on insulating carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

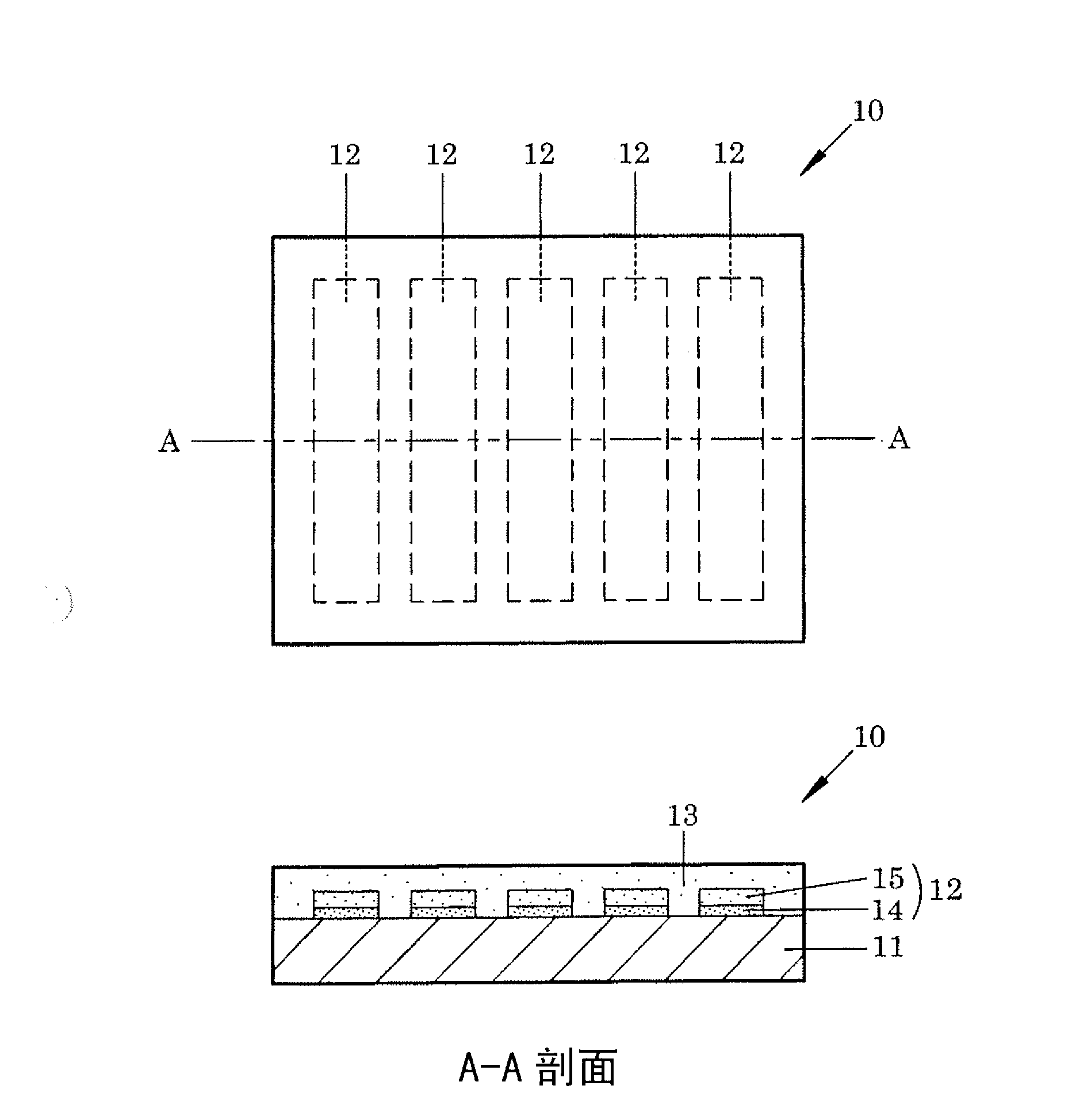

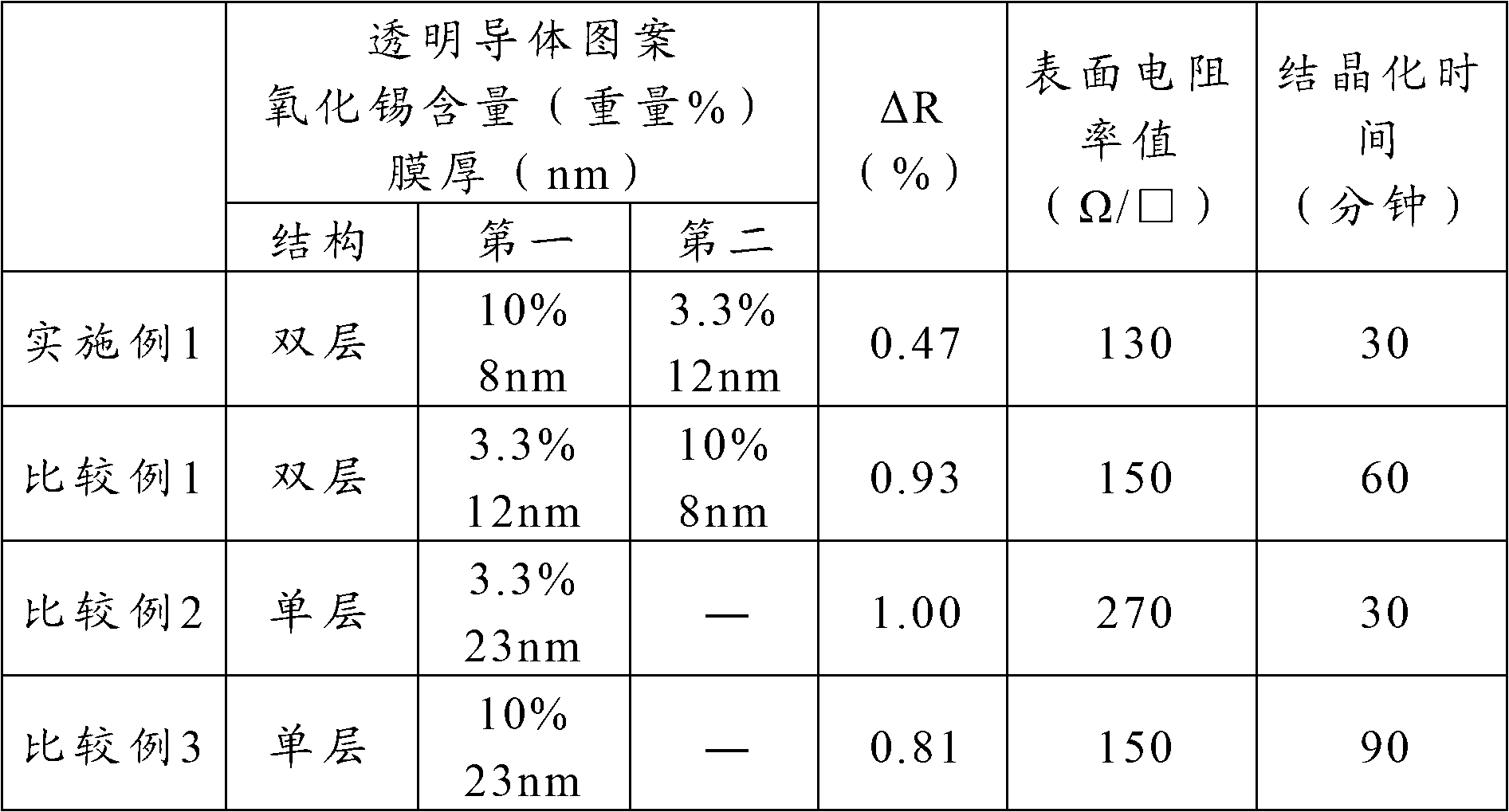

[0048] A primer layer (thickness 30 nm) of a thermosetting resin containing melamine resin was formed on a polyethylene terephthalate film having a thickness of 23 μm, and the film substrate 11 was prepared. The roll of the film substrate 11 is set in a sputtering device. The atmosphere in the sputtering device is a pressure of 0.4 Pa, and the specific composition of the gas is 80% by volume of argon and 20% by volume of oxygen. While unwinding the roll of the film substrate 11 at a certain speed, the first amorphous layer of indium tin oxide and the second amorphous layer of indium tin oxide are sequentially formed on the film substrate 11 to form a thickness of 20 nm Transparent conductor film. For the first amorphous layer of indium tin oxide, the content of tin oxide is 10% by weight and the thickness is 8 nm. For the second amorphous layer of indium tin oxide, the content of tin oxide is 3.3% by weight and the thickness is 12 nm. The film substrate 11 on which the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com