Silver contact structure and manufacturing method of a contact system

A technology of contact system and silver contact, which is applied in the field of improvement of contact points, can solve the problems that the mechanical strength of contacts cannot meet the performance requirements, the cost of contact materials has increased greatly, and the mechanical strength cannot meet the design requirements, etc. Achieve the effects of reducing labor intensity, reducing current density and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with the best examples.

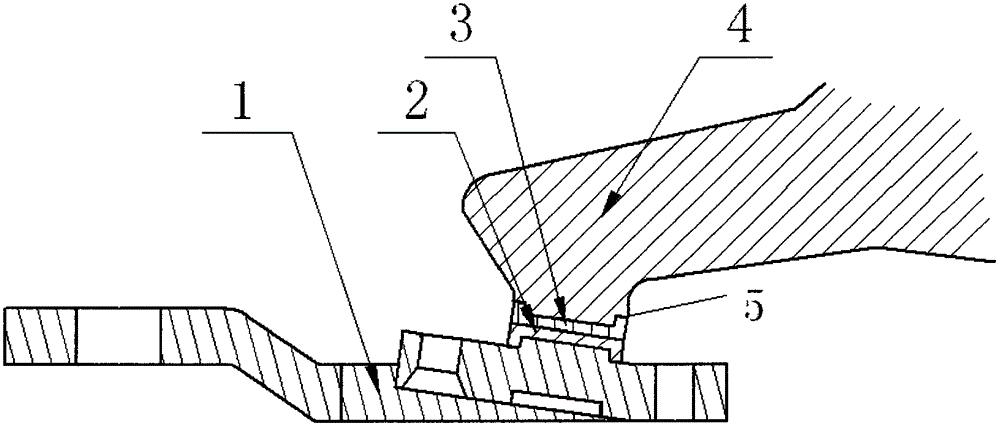

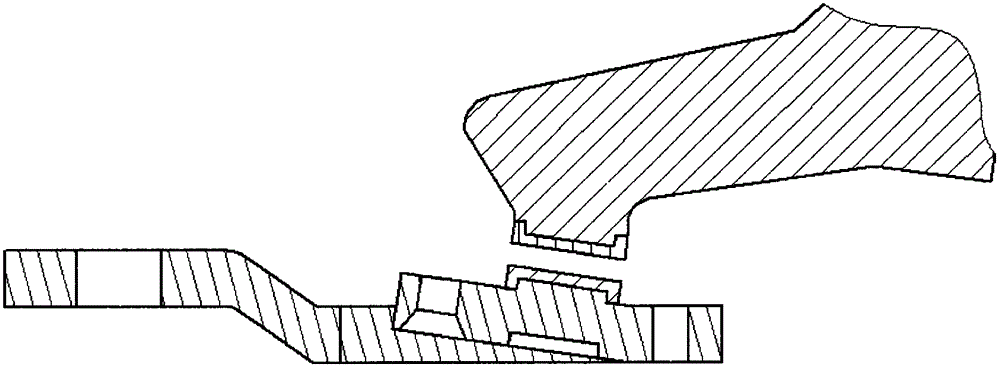

[0026] As shown in 1-6, a silver contact structure of a contact system includes a static contact 1, a static contact silver contact 2, a moving contact silver contact 3 and a moving contact 4; in the static contact 1 and There is a convex point on the contact point of the moving contact 4; there is a pressed groove surface on the silver contact 2 of the static contact and the silver contact 3 of the moving contact, and the silver contact 2 of the static contact and the silver contact 3 of the moving contact The groove surface is welded together with the raised points of the static contact 1 and the moving contact 4.

[0027] The groove surface of the silver contact 2 of the static contact and the silver contact 3 of the moving contact and the raised point of the fixed contact 1 and the moving contact 4 are all square structures; the four sides of the raised point, a bottom surface and a A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com