Method for semi-mechanically transplanting rice stubble rapes under condition of returning all straws

A technology of rape and straw, which is applied in the semi-mechanized transplanting field of rice stubble and rapeseed, which saves labor and labor, can solve the problems of saving labor and labor, rising activation costs, and high soil moisture, so as to reduce labor, reduce a large amount of labor, and eliminate pollution. environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Example: A semi-mechanized transplanting method of rice stubble and rapeseed under the condition of full return of rice straw

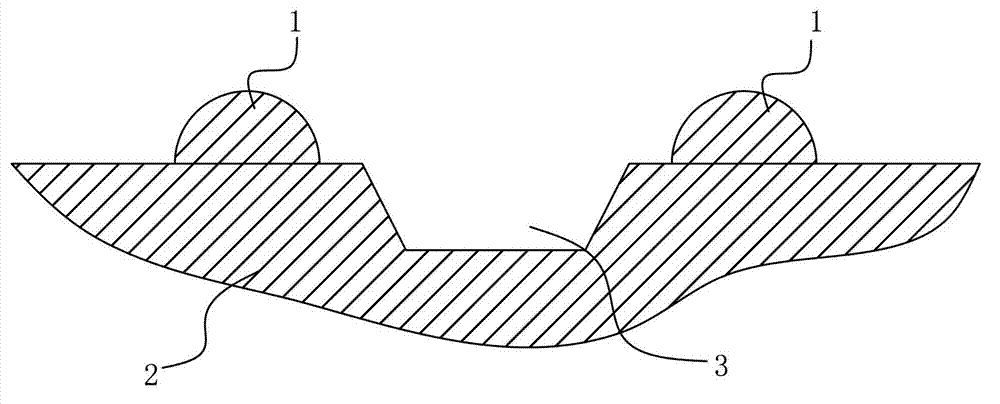

[0039] See attached figure 1 As shown, the specific steps are as follows:

[0040] In the first step, the rice straw is mechanically crushed and returned to the field in full

[0041] For the mature rice in the paddy field, the field dehydration is carried out 7 days before the rice is harvested; then a Kubota rice-wheat combine harvester with a straw chopping device and a straw evenly spreading device is used (company address: No. 77, Suhong East Road, Suzhou Industrial Park, Jiangsu Province) Carry out the harvesting operation; in the harvesting operation, the rice combine harvester keeps advancing in a straight line and harvests close to the ground, reduces the height of the rice piles left in the paddy field 2, and keeps the height of the rice piles in the paddy field 2 at 5 centimeters, The length of the rice straw chopped by the straw c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com