Die for radially-oriented sintered NdFeB magnetic ring and production process thereof

A technology of radiation orientation and manufacturing process, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., it can solve the problems that the number of magnetized magnetic poles cannot be changed at will, thin-walled parts cannot be produced, and the utilization rate of raw materials is low. Achieve stable and reliable product quality, small size and shape restrictions, and high performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

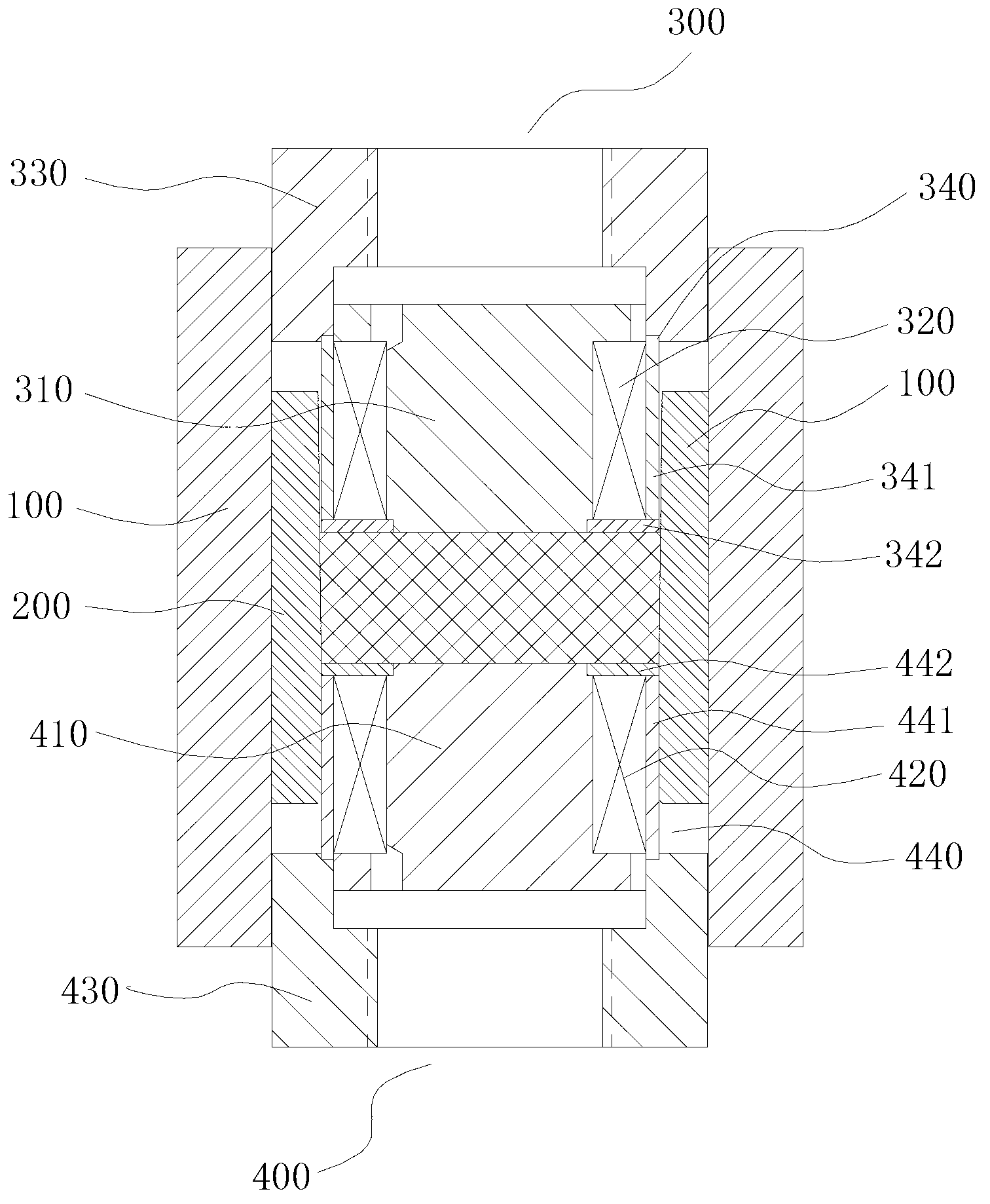

[0029] See figure 1 , A radiation-oriented sintered neodymium iron boron magnetic ring mold, including a magnetically conductive and magnetically concentrated magnetic ring 100, a female mold 200 for accommodating magnetic powder, an upper indenter assembly 300 and a lower indenter assembly 400, The magnetic flux collecting ring 100 and the female mold 200 are annular, the female mold 200 is arranged in the magnetic flux collecting ring 100, the upper indenter assembly 300 and the lower indenter assembly 400 are arranged in the female mold 200 and the upper indenter assembly The pressing surfaces of the upper pressing head assembly 300 and the lower pressing head assembly 400 are arranged opposite to each other, and the pressing surfaces of the upper pressing head assembly 300 and the lower pressing head assembly 400 have the same cross-sectional area as the cavity of the female mold 200. When working in this way, the upper indenter assembly 300 and the lower indenter assembly 4...

Embodiment 2

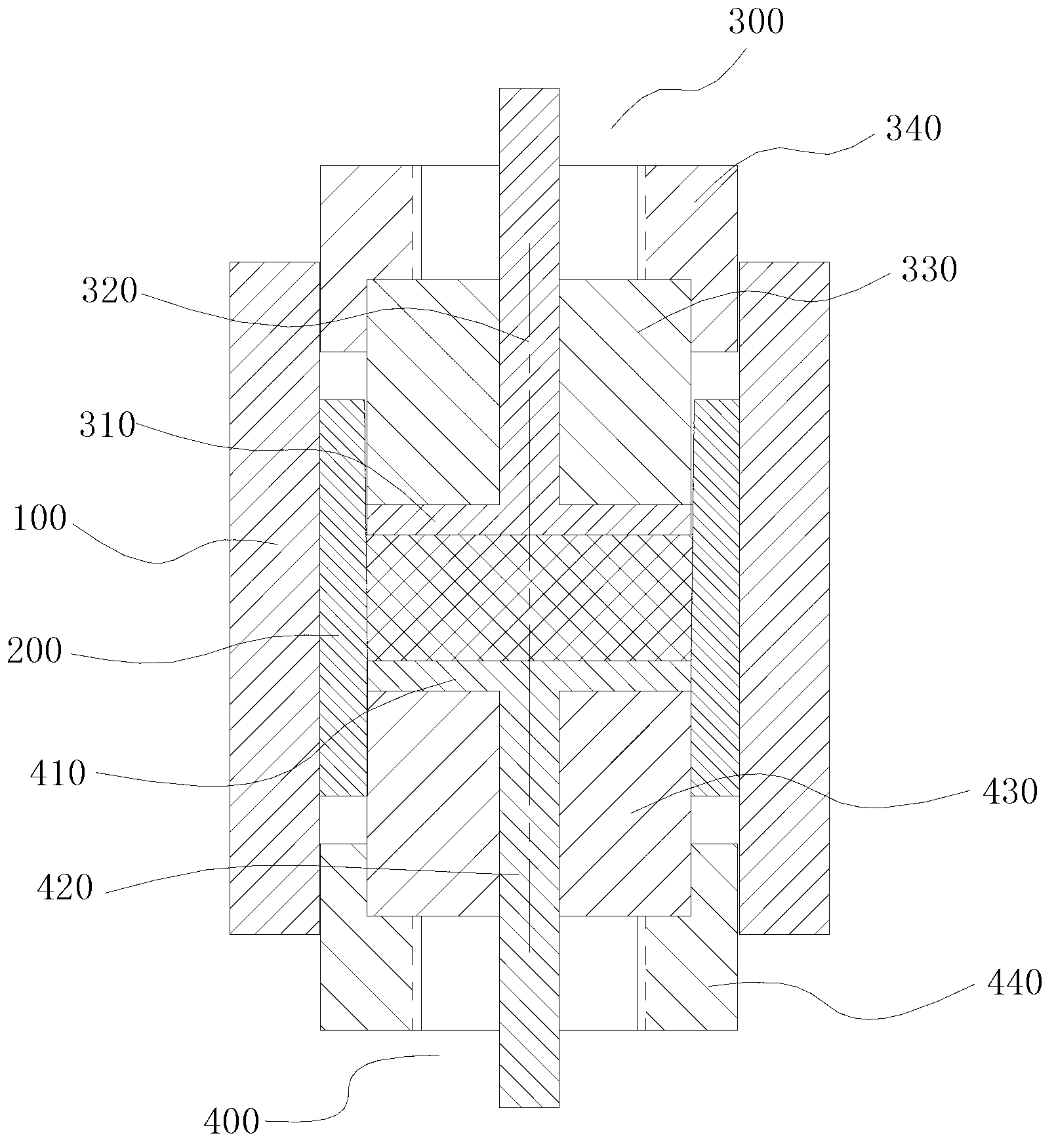

[0045] See figure 2 , A radiation-oriented sintered neodymium iron boron magnetic ring mold, including a magnetically conductive and magnetically concentrated magnetic ring 100, a female mold 200 for accommodating magnetic powder, an upper indenter assembly 300 and a lower indenter assembly 400, The magnetic flux collecting ring 100 and the female mold 200 are annular, the female mold 200 is arranged in the magnetic flux collecting ring 100, the upper indenter assembly 300 and the lower indenter assembly 400 are arranged in the female mold 200 and the upper indenter assembly The pressing surfaces of the upper pressing head assembly 300 and the lower pressing head assembly 400 are arranged opposite to each other, and the pressing surfaces of the upper pressing head assembly 300 and the lower pressing head assembly 400 have the same cross-sectional area as the cavity of the female mold 200. When working in this way, the upper indenter assembly 300 and the lower indenter assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com