Garbage can cleaning system

A cleaning system and trash can technology, applied in the field of cleaning systems, can solve the problems of high labor intensity, low cleaning efficiency, and high cleaning cost, and achieve the effects of reducing labor intensity, saving water consumption, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

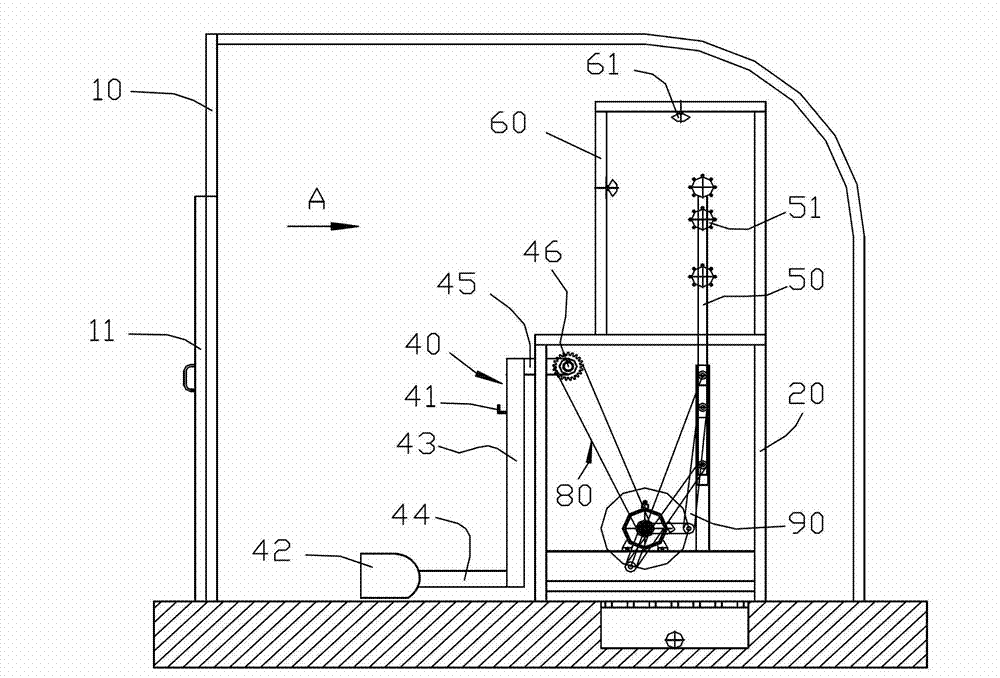

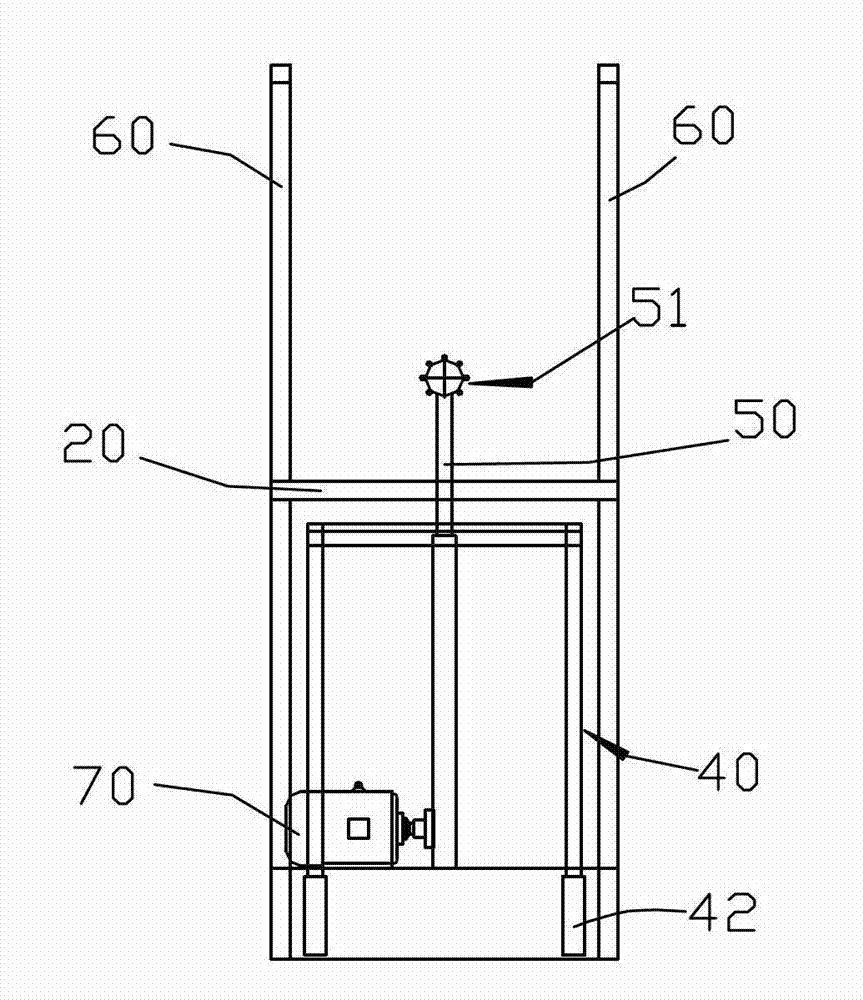

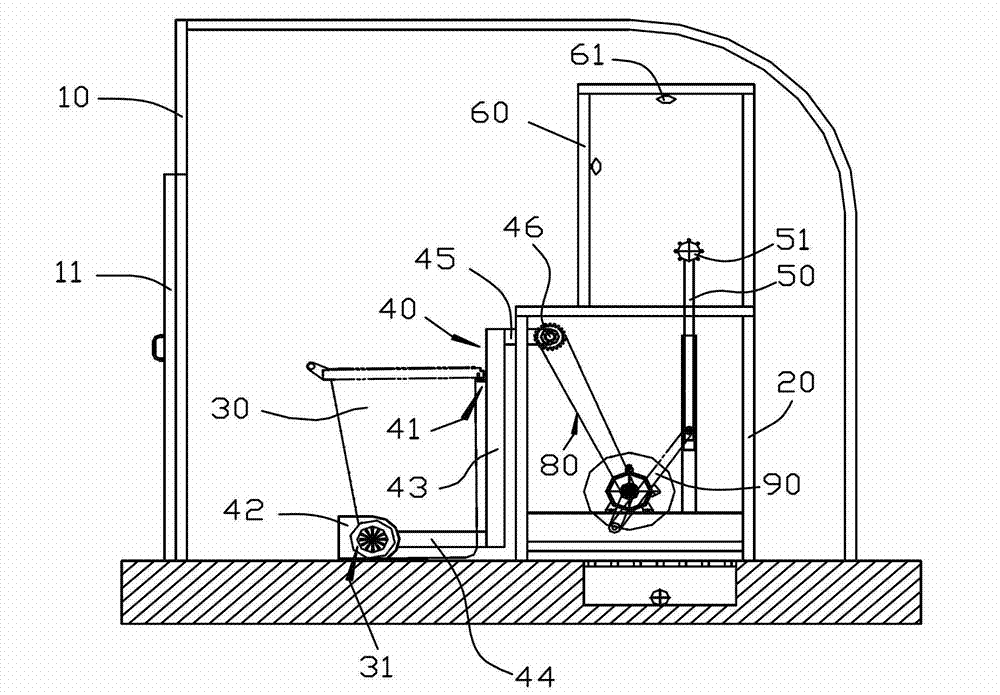

[0011] see Figure 1-5 , the technical solution adopted in the present invention is: a garbage can cleaning system, including a cover body 10, a frame 20 is arranged in the chamber surrounded by the cover body 10, and a frame 20 is provided on the frame 20 to be connected with a turning mechanism and used to hold garbage. The clamping mechanism of the bucket 30, the clamping mechanism is driven by the power mechanism through the overturning mechanism to perform the overturning movement, and the garbage can 30 is overturned by the overturning mechanism to present the state that the mouth of the bucket is facing upwards or downwards, and the frame 20 There is also a cleaning mechanism for cleaning the inside and outside of the trash can 30, and a sewage collection and discharge mechanism is arranged below it. The cover 10 provided in the present invention covers the sewage produced by cleaning in the chamber surrounded by the cover 10, thereby limiting the wanton splashing of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com