Heat-sealing adhesive for polystyrene and preparation method of heat-sealing adhesive

A technology of polystyrene and adhesives, applied in the direction of ester copolymer adhesives, hydrocarbon copolymer adhesives, adhesive types, etc., can solve the problem of not being able to seal polystyrene materials, and achieve a wide range of The effect of heat-sealing temperature range, simple and easy preparation method, and high heat-sealing adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The concrete preparation method of above-mentioned heat-sealing adhesive for polystyrene, process steps are as follows:

[0030] (1) Put the mixed solvent into the reaction kettle with stirring and condensing reflux, and fully stir at the speed of 800-1000r / min;

[0031] (2) Keep stirring at a speed of 800-1000r / min, put vinyl chloride copolymer resin, styrene copolymer resin, and acrylate copolymer resin into the reactor in turn, and raise the temperature to 45-60°C, keep stirring for 2-2.5 hours;

[0032] (3) Cool and filter to obtain heat-sealing adhesive for polystyrene.

Embodiment 1

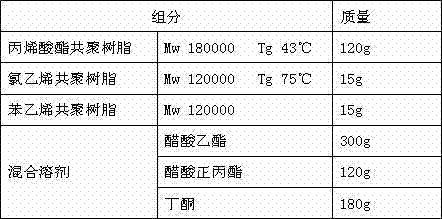

[0035] A heat-sealing adhesive for polystyrene, composed of ingredients according to the following mass:

[0036]

[0037] Add a mixed solvent of ethyl acetate, n-propyl acetate, and butanone into a three-necked flask with a capacity of 1 L and equipped with a heating mantle, a thermometer, a condenser, and a mechanical stirring device, and start stirring; while stirring, add vinyl chloride copolymer resin, Styrene copolymer resin and acrylate copolymer resin were heated up to 50° C. and kept for 2 hours; heating was stopped, cooled to room temperature while stirring, and filtered to obtain 750 g of heat-sealing adhesive for colorless transparent polystyrene.

[0038] The obtained polystyrene is coated with a heat-sealing adhesive on a 0.02mm hard aluminum foil and dried, and then heat-sealed with the polystyrene sheet on a heat-sealing device (heat-sealing conditions are 0.2MPa, 150°C, 1s), Its heat sealing strength was measured to reach 9.8N / 15mm.

Embodiment 2

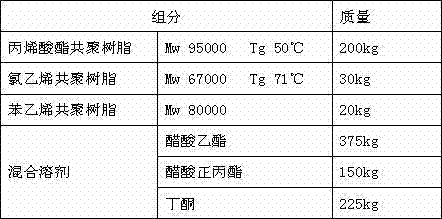

[0040] A heat-sealing adhesive for polystyrene, composed of ingredients according to the following mass:

[0041]

[0042] Add a mixed solvent of ethyl acetate, n-propyl acetate and butanone into a 1-ton reaction kettle with heating, reflux condenser, and mechanical stirring, and start stirring; while stirring, add vinyl chloride copolymer resin, styrene Copolymer resin, acrylate copolymer resin, and raise the temperature to 50°C and keep it for 2 hours; stop heating, cool down while stirring, cool to room temperature, and filter to obtain 1000kg colorless transparent polystyrene heat-sealing adhesive.

[0043] The obtained heat-sealing adhesive for polystyrene is coated on a 0.02mm hard aluminum foil on an aluminum foil printing coating machine, dried and rolled, and heat-sealed with a polystyrene sheet of matching specifications on a blister packaging machine ( The heat sealing conditions of the packaging machine are 0.4MPa, 200°C, 0.7s), and the heat sealing strength is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com