Heat-sealing adhesive for polystyrene and preparation method of heat-sealing adhesive

A polystyrene and adhesive technology, used in ester copolymer adhesives, hydrocarbon copolymer adhesives, adhesive types, etc., can solve problems such as inability to seal polystyrene materials, and achieve a wide range of The effect of heat-sealing temperature range, high heat-sealing adhesive strength, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The concrete preparation method of above-mentioned heat-sealing adhesive for polystyrene, process steps are as follows:

[0030] (1) Put the mixed solvent into the reaction kettle with stirring and condensing reflux, and fully stir at the speed of 800-1000r / min;

[0031] (2) Keep stirring at a speed of 800-1000r / min, put vinyl chloride copolymer resin, styrene copolymer resin, and acrylate copolymer resin into the reactor in turn, and raise the temperature to 45-60°C, keep stirring for 2-2.5 hours;

[0032] (3) Cool and filter to obtain heat-sealing adhesive for polystyrene.

Embodiment 1

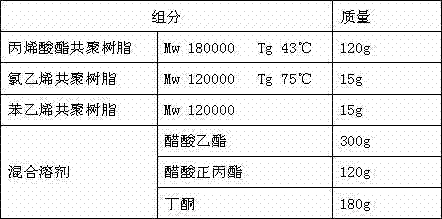

[0035] A heat-sealing adhesive for polystyrene, composed of ingredients according to the following mass:

[0036]

[0037] Add a mixed solvent of ethyl acetate, n-propyl acetate, and butanone into a three-necked flask with a capacity of 1 L and equipped with a heating mantle, a thermometer, a condenser, and a mechanical stirring device, and start stirring; while stirring, add vinyl chloride copolymer resin, Styrene copolymer resin and acrylate copolymer resin were heated up to 50° C. and kept for 2 hours; heating was stopped, cooled to room temperature while stirring, and filtered to obtain 750 g of heat-sealing adhesive for colorless transparent polystyrene.

[0038] The obtained polystyrene is coated with a heat-sealing adhesive on a 0.02mm hard aluminum foil and dried, and then heat-sealed with the polystyrene sheet on a heat-sealing device (heat-sealing conditions are 0.2MPa, 150°C, 1s), Its heat sealing strength was measured to reach 9.8N / 15mm.

Embodiment 2

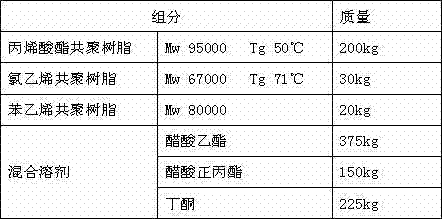

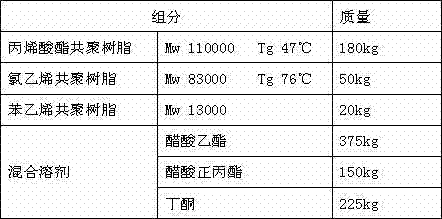

[0040] A heat-sealing adhesive for polystyrene, composed of ingredients according to the following mass:

[0041]

[0042] Add a mixed solvent of ethyl acetate, n-propyl acetate and butanone into a 1-ton reaction kettle with heating, reflux condenser, and mechanical stirring, and start stirring; while stirring, add vinyl chloride copolymer resin, styrene Copolymer resin, acrylate copolymer resin, and raise the temperature to 50°C and keep it for 2 hours; stop heating, cool down while stirring, cool to room temperature, and filter to obtain 1000kg colorless transparent polystyrene heat-sealing adhesive.

[0043] The obtained heat-sealing adhesive for polystyrene is coated on a 0.02mm hard aluminum foil on an aluminum foil printing coating machine, dried and rolled, and heat-sealed with a polystyrene sheet of matching specifications on a blister packaging machine ( The heat sealing conditions of the packaging machine are 0.4MPa, 200°C, 0.7s), and the heat sealing strength is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com