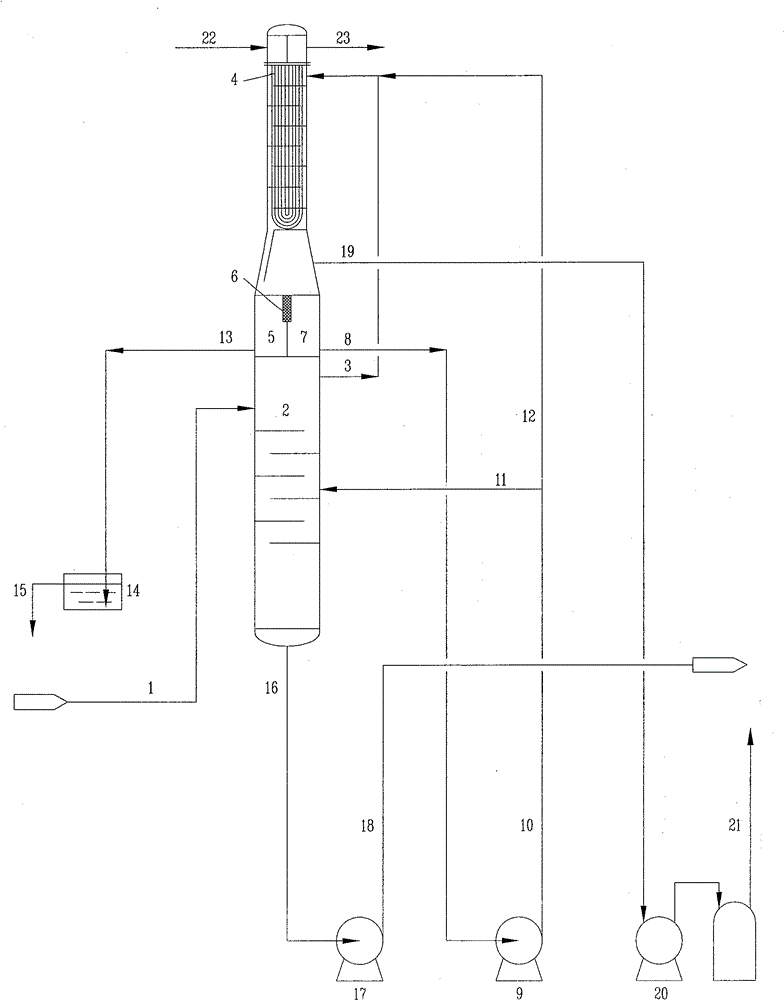

Composite function single-tower diesel or jet fuel vacuum dehydration process

A technology of jet fuel and process method, which is applied in the field of removing moisture from diesel or jet fuel, can solve problems such as affecting product quality, turbidity and opacity of diesel, and achieve the effects of good oil-water separation, less land occupation, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The feed takes diesel as an example:

[0029] 0.66MPaG, 205°C, 44t / h diesel oil 1 enters the vacuum tower 2, and completes equilibrium flash evaporation at the lower part of the vacuum tower under an absolute pressure of 50KPa. Gasification of water and part of diesel oil, 195°C, 2.9t / h water-containing oil gas 3 is mixed with condensed 40°C, 10.9t / h diesel oil 12, the temperature drops to 98°C and enters the upper part of the vacuum tower 2, and condenses to 40°C, falls into the upper tower kettle A5 of the vacuum tower 2, condensed oil at 40℃, 13.6t / h enters the tower kettle B7 through the coalescing material 6, and then is pumped out by the pump 9 to the outlet pipeline 10 through the pipeline 8, and then divided into Two streams (11, 12): stream 12 is mixed with water-containing oil and gas 3; 40°C, 2.7t stream 11 returns to the lower part of the vacuum tower for secondary flash evaporation.

[0030] The oil-water mixture falling into the upper tower kettle A5 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com