Dry backflash arrestor

A dry tempering and preventer technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of short service life, easy tempering, poor stability, etc., and achieve beautiful appearance and firm structure Reasonable, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

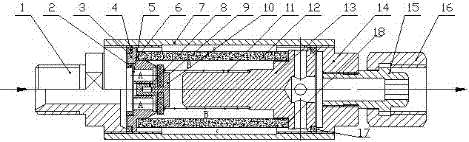

[0011] A dry flashback preventer, the device includes a front cover 1, a front gland 3, a rubber seal assembly, a rear gland assembly, a rear end cover 14 and a copper pipe 7, and the front end cover 1 and the rear end cover 14 are connected to The two ends of the copper pipe 7, the rear part of the rear end cover 14 is fixedly connected to a threaded connection pipe 15 with a nut 16, the copper pipe 7 is provided with a front gland 3, a rubber seal assembly and a rear gland assembly, The rubber seal assembly is arranged in the rear end hole of the front gland 3, the rear gland assembly is arranged at the front of the rear end cover 14, and one end of the spring 11 on the rear gland assembly is sleeved on the rubber seal assembly On the joint cap 10, a powder metallurgy porcelain sleeve 12 is provided between the rear gland assembly and the front gland 3, and the rear gland assembly includes a rear gland 13, a gasket one 17, an adjustment pad one 18 and The spring 11, the wash...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap