Surface ash clearing device of pipe heat exchanger

A technology of tubular heat exchanger and cleaning device, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., which can solve the problems of increased flue gas humidity, high maintenance costs, and dust accumulation, and achieves convenience clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

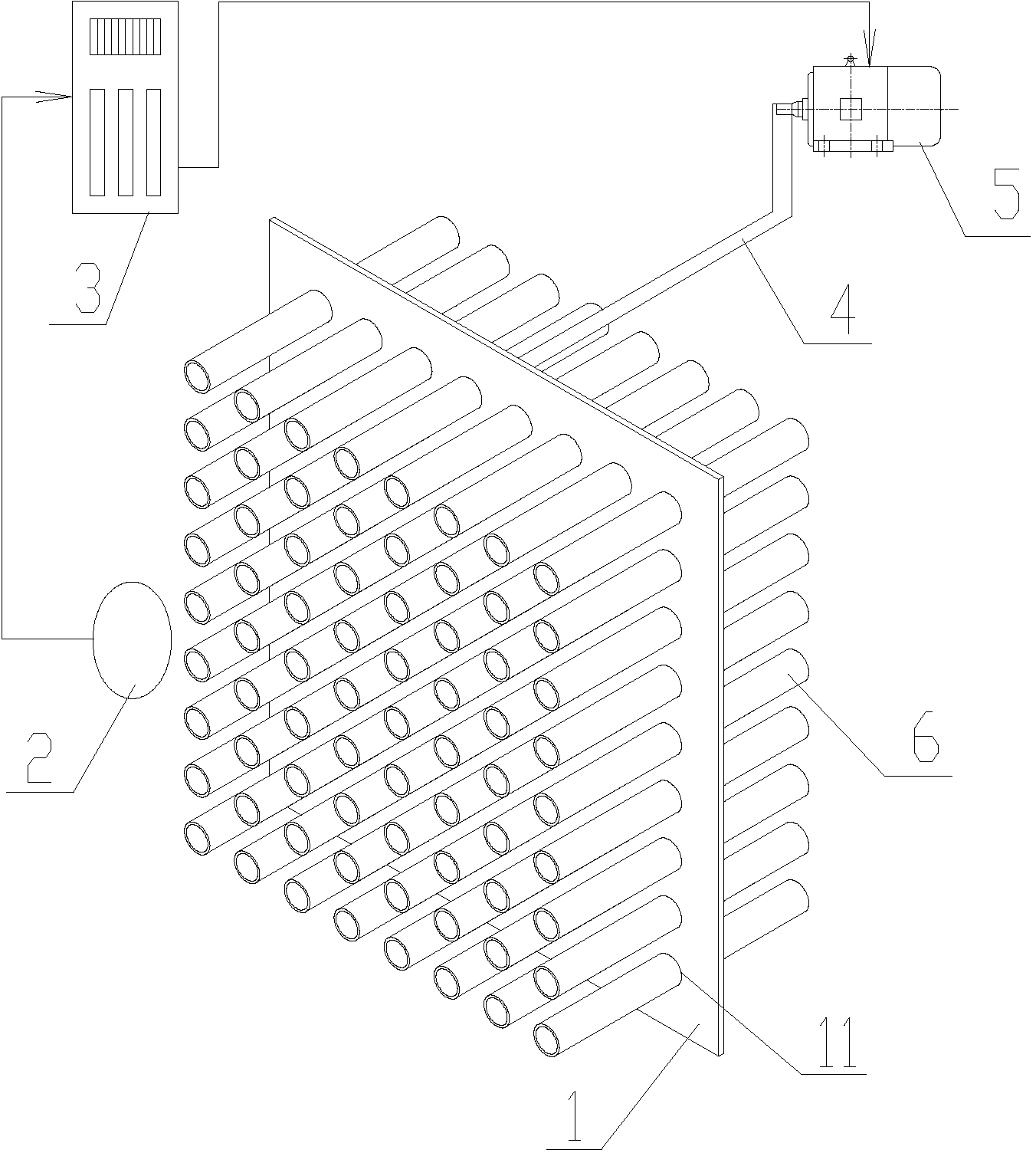

[0011] Such as figure 1 As shown, the device for removing dust on the surface of the tubular heat exchanger of the present invention includes a heat exchanger tube bundle arranged in the flue, a dust removal orifice plate 1, a driving connecting rod 4, a smoke resistance sensor 2, a motor 5 and a controller 3. The dust removal orifice 1 is provided with a plurality of through holes 11 and penetrates into the outer rings of the heat exchange tubes 6 of the heat exchanger tube bundle respectively. The output end of the controller 3 is connected to the control signal input end of the motor 5 , the smoke resistance sensor 2 is arranged in the flue and the signal output end is connected to the signal input end of the controller 3 .

[0012] Furthermore, the diameters of the several through holes 11 of the dust removal orifice plate 1 are larger than the outer diameter of the heat exchange tube 6 . The diameter of several through holes of the dust removal orifice is larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com