Blankmask and photomask using the same

一种光掩膜、遮光膜的技术,应用在言领域,能够解决难以检验硬膜及金属膜、光掩膜分辨率及图案保真度限制、反射率增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, exemplary embodiments of the present invention will be explained in detail with reference to the accompanying drawings. While the invention has been shown and described in conjunction with exemplary embodiments thereof, it will be obvious to those skilled in the art that various modifications may be made without departing from the spirit and scope of the invention.

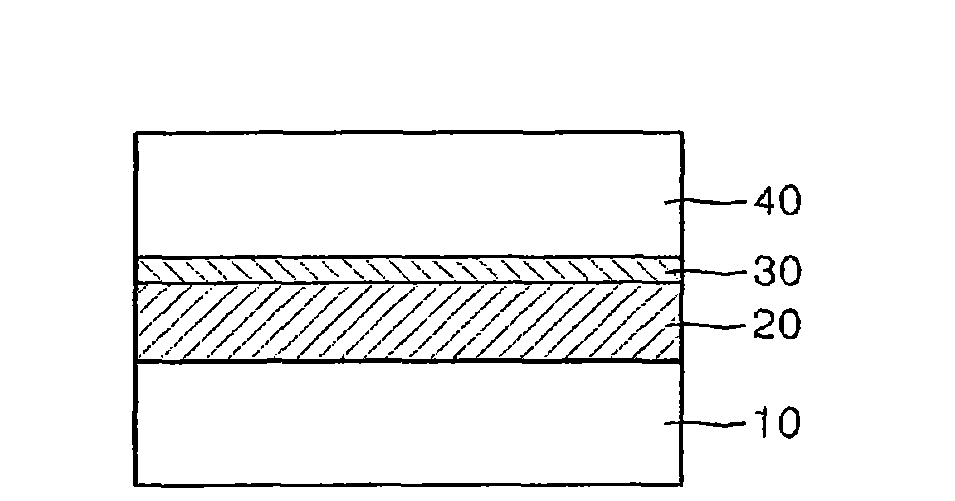

[0055] image 3 is a cross-sectional view of a blank mask 100 for a hard mask according to an embodiment of the present invention.

[0056] refer to image 3 , the blank mask 100 for hard mask has a structure in which a transparent substrate 110, a metal film 120, a hard film 130, and a resist film 140 are sequentially stacked.

[0057] Specifically, the transparent substrate 110 has a size of 6 inches×6 inches×0.25 inches (width×height×thickness), and has a transmittance of 90% or more at an exposure wavelength of 200 nm or less. When using immersion lithography, the birefringence rate of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com