Constant current source circuit and sampling circuit

A technology of sampling circuit and constant current source, which is applied in the direction of light source, electric light source, electrical components, etc., can solve the problems of high power loss and loss, and achieve the effect of increasing power, reducing power consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

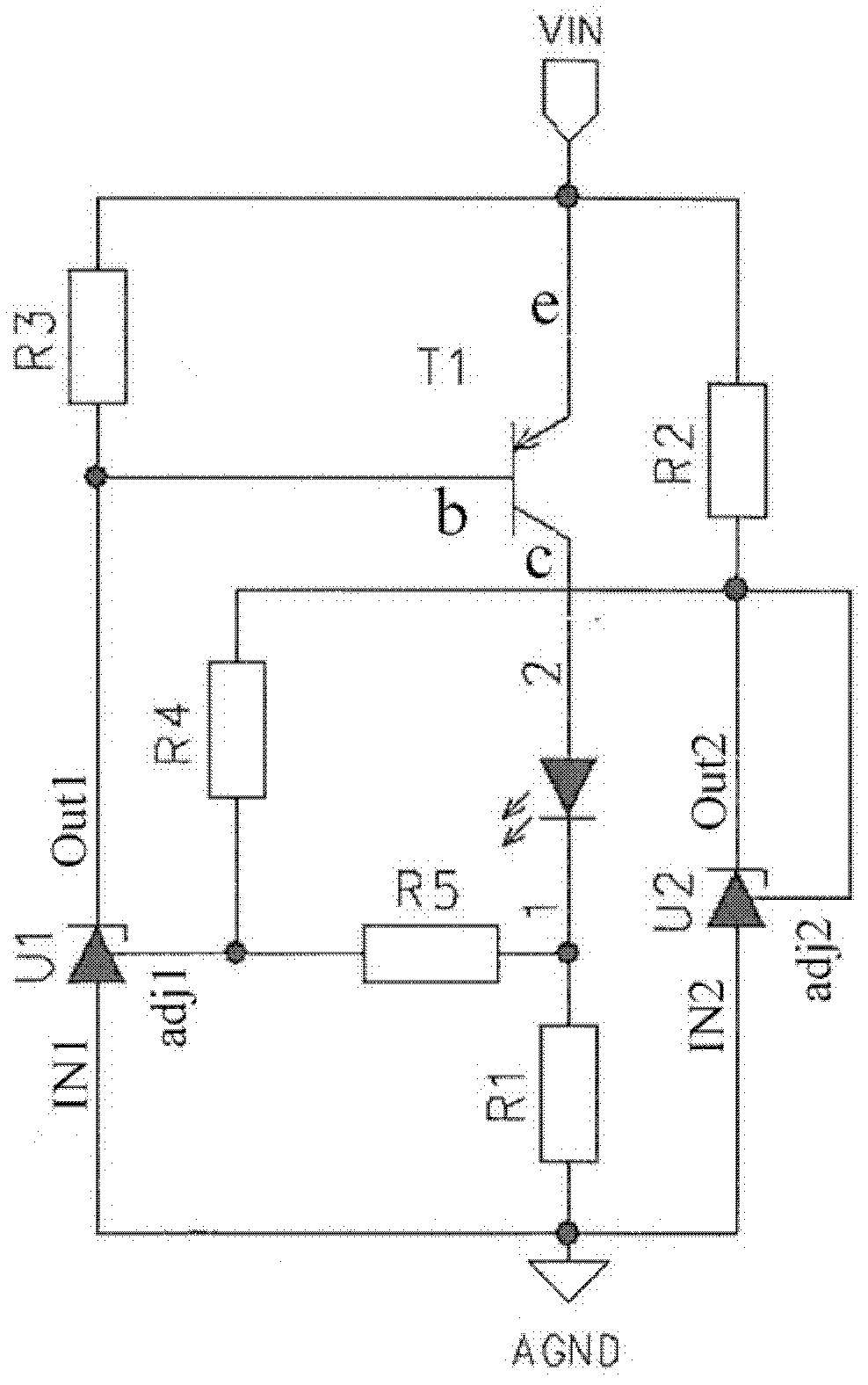

[0026] image 3 A specific embodiment of the constant current source circuit according to the present invention is shown. Such as image 3 As shown, the constant current source circuit includes: a main circuit including a transistor T1, a plurality of light-emitting diodes connected in series as a load, a first three-terminal voltage regulator U1, a sampling resistor R1, and a third resistor R3; An adjustment unit of the second three-terminal voltage regulator U2, the second resistor R2, the fourth resistor R4, and the fifth resistor R5 of the voltage stabilizing unit.

[0027] The output terminal Out1 of the first regulator U1 is connected to the voltage input terminal VIN through the third resistor R3, and the third resistor R3 is connected between the base b of the transistor T1 and the voltage input terminal VIN. The emitter e of the transistor T1 is connected to the voltage input terminal VIN, and the collector c of the transistor T1 is connected to the anode terminals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com