LDMOS (Laterally Diffused Metal Oxide Semiconductor) transistor and manufacturing method thereof

A technology of transistors and semiconductors, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of not being able to increase the breakdown voltage of LDMOS transistors, reduce the breakdown voltage of LDMOS transistors, etc., so as to improve the breakdown voltage, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

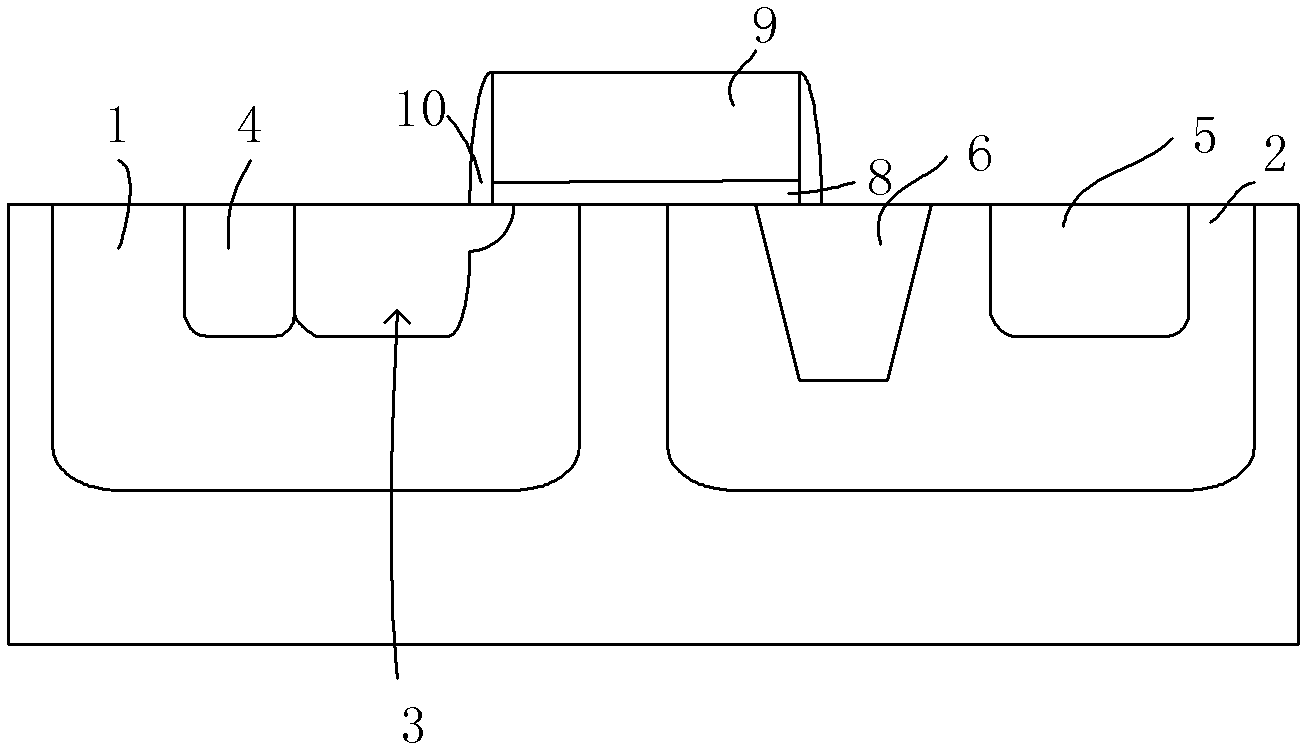

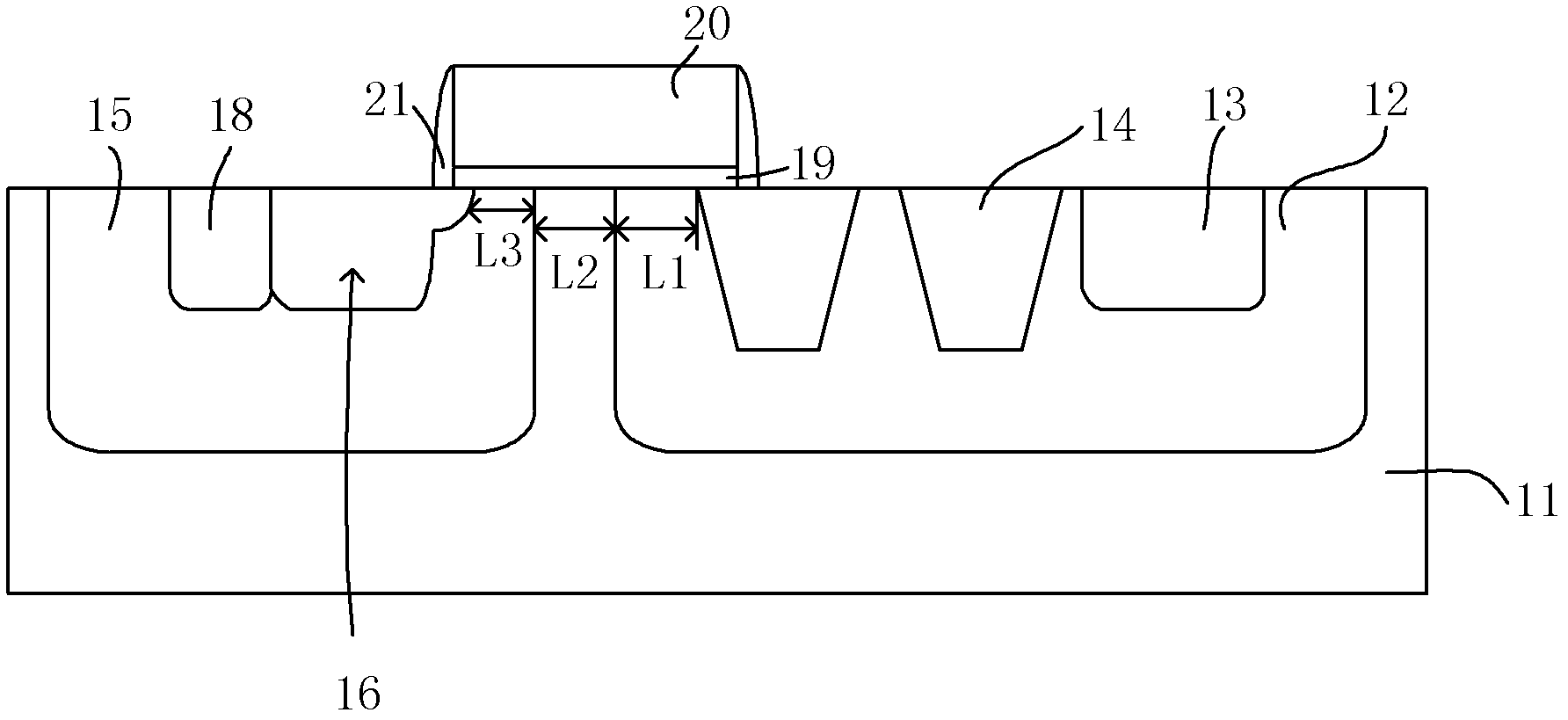

[0039] In order to increase the breakdown voltage of the LDMOS transistor, one of the methods that those skilled in the art can think of is to increase the width of the STI structure between the source region and the drain region of the transistor, but it will be found that this method does not The purpose of increasing the breakdown voltage of the transistor cannot be achieved. On the contrary, in some cases this practice even lowers the breakdown voltage of the transistor. Therefore, technicians have to improve the breakdown voltage of the LDMOS transistor from other perspectives, such as replacing the material filling the STI structure and increasing the overall size of the device.

[0040] The inventor found in practice that the reason for this phenomenon (increasing the width of the STI structure between the transistor source region and the drain region cannot increase the breakdown voltage of the transistor) is that the shallow trenches in the STI structure are etched by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com