Pressure adjustable type subsurface irrigation system

An adjustable underground infiltration irrigation technology, applied in the field of agricultural irrigation, can solve the problems of low water use efficiency, difficult negative pressure adjustment, and large energy waste, and achieve the effects of saving equipment investment, flexible and convenient adjustment, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

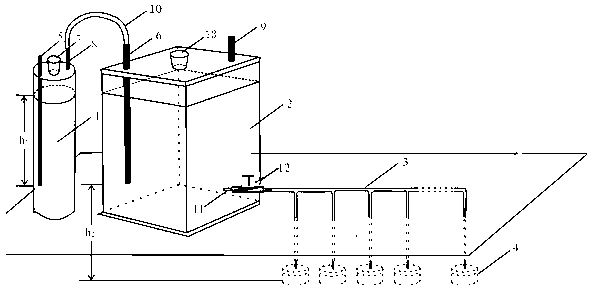

[0014] Example 1, see figure 1 , taking underground negative pressure seepage irrigation as an example, the emitter 4 is buried in the ground and connected with the water capillary 3. The emitter 4 is water-permeable and airtight, and is made of clay material. The water capillary 3 is passed through a control switch 12 The water outlet 11 is connected with the water supply chamber 2, the lower end of the water supply chamber 2 is sealed, and the upper part of the water supply chamber 2 is provided with an air extraction nozzle 9, which is used to extract the gas in the closed space of the water supply chamber 2. There is a water inlet above the water supply chamber 2, and the water inlet The water port can be sealed by the second sealing plug 13; the lower end of the pressure regulating chamber 1 is sealed, and the upper end has a water inlet and is sealed with the first sealing plug 7; the first air intake pipe 5 that can move up and down is inserted into the interior through...

Embodiment 2

[0016] Embodiment 2, taking underground non-pressure seepage irrigation as an example, the system connection part is the same as that of Embodiment 1, the difference is that the emitter 4 is a common emitter, and the control switch 12 is closed before irrigation, and the pressure regulating chamber 1 and the water supply chamber 2 are connected to each other. Fill the water inside to the predetermined position, use the sealing plug to seal the pressure regulating chamber 1 and the water supply chamber 2, and adjust the positions of the first air inlet pipe 5 and the second air inlet pipe 6 according to the needs, and the distance between the end of the first air inlet pipe 5 and the pressure regulating chamber 1 The distance of the inner water surface is recorded as h 1 , the distance from the end of the second air intake pipe 6 to the emitter 4 is denoted as h 2 , and require h 2 equal to h 1 ; Open the switch 12, under the effect of water pressure and soil suction, the wat...

Embodiment 3

[0017] Embodiment 3, taking the underground pressurized seepage irrigation as an example, the system connection part is the same as that of Embodiment 1, the difference is that the emitter 4 is a common emitter, and the control switch 12 is closed before irrigation, and the pressure regulating chamber 1 and the water supply chamber 2 are connected to each other. Fill the water inside to the predetermined position, use the sealing plug to seal the pressure regulating chamber 1 and the water supply chamber 2, and adjust the positions of the first air inlet pipe 5 and the second air inlet pipe 6 according to the needs, and the distance between the end of the first air inlet pipe 5 and the pressure regulating chamber 1 The distance of the inner water surface is recorded as h 1 , the distance from the end of the second air intake pipe 6 to the emitter 4 is denoted as h 2 , and require h 2 greater than h 1 ; Open the switch 12, under the effect of water pressure and soil suction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com