Preparation process for instant canned anchovy

A preparation process and technology for anchovies are applied in the field of preparation of ready-to-eat canned anchovies, and can solve the problems of easily damaged and rotten anchovies, lack of convenience for eating, long storage time, and the like, achieving long storage time, less nutrient loss, and convenient eating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

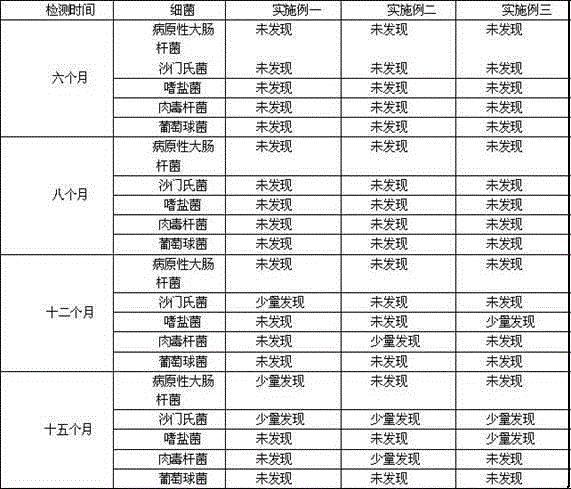

Examples

Embodiment 1

[0030] A preparation process of instant canned anchovy, the operation steps are as follows:

[0031] (1) Pretreatment: choose fresh or frozen and thawed anchovies, remove the head, tail, fins, viscera, bone spurs and scales, then wash the fish body with clean water and set aside;

[0032] (2) Deodorization: first, soak the anchovies pretreated in step (1) for 30 minutes with the deodorization liquid, the weight ratio of the deodorization liquid to the anchovies is 2:1, and the deodorization liquid contains CaCl 2 Mixed solution with HCl, CaCl 2 The mass concentration of HCl is 0.3%, and the mass concentration of HCl is 0.05%; then, the anchovy is rinsed to neutrality with ice water and then soaked in rice wine for 15min, and the weight ratio of rice wine and anchovy is 2:1; finally, first Rinse with ice water and then soak in green tea water for 1 hour; the soaking temperature is 20°C, and the weight ratio of green tea water to anchovy is 4:1; green tea water is brewed by add...

Embodiment 2

[0039] A preparation process of instant canned anchovy, the operation steps are as follows:

[0040] (1) Pretreatment: choose fresh or frozen and thawed anchovies, remove the head, tail, fins, viscera, bone spurs and scales, then wash the fish body with clean water and set aside;

[0041] (2) Deodorization: First, soak the anchovies pretreated in step (1) for 45 minutes with the deodorization solution, the weight ratio of the deodorization solution to the anchovy is 2.5:1, and the deodorization solution contains CaCl 2 Mixed solution with HCl, CaCl 2 The mass concentration of HCl is 0.2%, and the mass concentration of HCl is 0.08%; Then, the anchovy is rinsed with ice water to neutrality and then soaked in rice wine for 20min, and the weight ratio of rice wine and anchovy is 1:1; finally, first Rinse with ice water and then soak in green tea water for 2.5 hours; the soaking temperature is 30°C, the weight ratio of green tea water to anchovy is 2:1; green tea water is brewed by ...

Embodiment 3

[0048] A preparation process of instant canned anchovy, the operation steps are as follows:

[0049] (1) Pretreatment: choose fresh or frozen and thawed anchovies, remove the head, tail, fins, viscera, bone spurs and scales, then wash the fish body with clean water and set aside;

[0050] (2) Deodorization: First, soak the anchovies pretreated in step (1) for 90 minutes with the deodorization liquid, the weight ratio of the deodorization liquid to anchovies is 1.5:1, and the deodorization liquid contains CaCl 2 Mixed solution with HCl, CaCl 2 The mass concentration of HCl is 0.25%, and the mass concentration of HCl is 0.1%; then, the anchovy is rinsed with ice water to neutrality and then soaked in rice wine for 10min, and the weight ratio of rice wine and anchovy is 1.5:1; finally, first Rinse with ice water and then soak in green tea water for 3 hours; the soaking temperature is 10°C, the weight ratio of green tea water to anchovy is 3:1; green tea water is brewed by adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com