Hot rolling device used for hot rolling production of copper and copper alloy plate strip blank and rolling method thereof

A copper alloy plate and copper alloy technology, applied in the direction of metal rolling, metal rolling, roll, etc., can solve the problems of restricting the yield of the billet, reducing the production efficiency of the billet, affecting the improvement of the production efficiency of the billet, etc., and improving the yield of the billet. , The effect of eliminating the edge cracks of the billet and reducing the production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

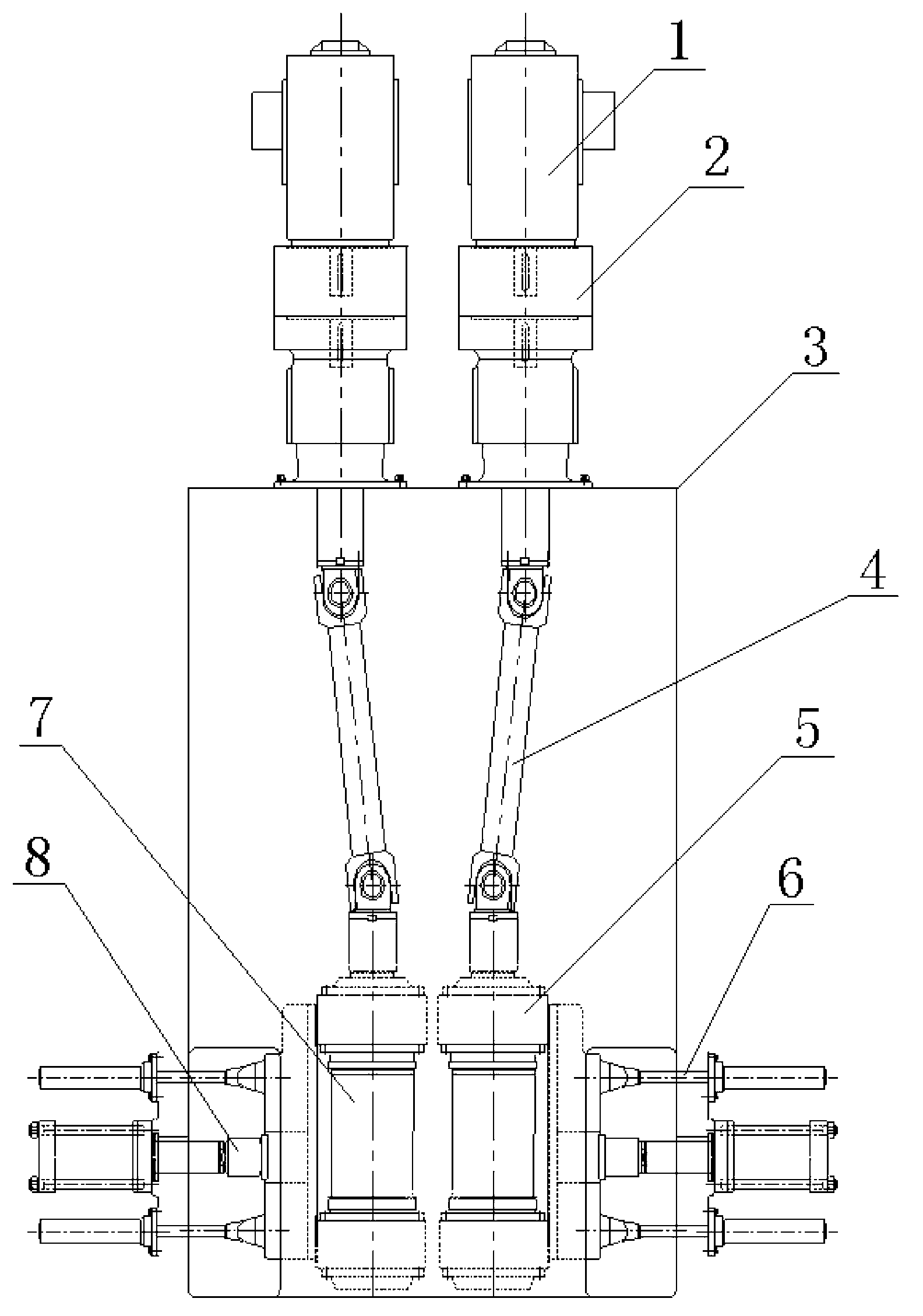

[0022] Depend on figure 1 It can be seen from the shown structure that this kind of hot rolling device for hot rolling production of copper and copper alloy strip blanks includes edge rolls 7 installed inside the mechanism frame 3, and the fast rolling of edge rolls 7 is realized by pinch roll oil cylinders 6. On and off, the motor 1 drives the edge roller 7 to perform rolling through the reducer 2 and the coupling 4, the rolling oil cylinder 8 is connected with the edge roller bearing housing 5, and the rolling force provided by the rolling oil cylinder 8 passes through the edge roller The bearing housing 5 is applied on the edge roll 7, and the rolling oil cylinder 8 is used to realize the stable rolling of the edge roll 7, and the hot rolling device is symmetrically arranged on the entrance and exit sides of the hot rolling mill, and the edge of the hot-rolled ingot is respectively implemented. rolling.

[0023] The edge roll 7 is conical, and the generatrix from one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com