Automatic zooming method and automatic zooming device for laser cutting machine

A laser cutting machine, automatic zoom technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of not being able to automatically adjust the lens focal length, etc., to achieve cutting expansion, eliminating additional costs and errors, and uniform laser energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples serve to illustrate the invention, but do not limit it. The details and working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

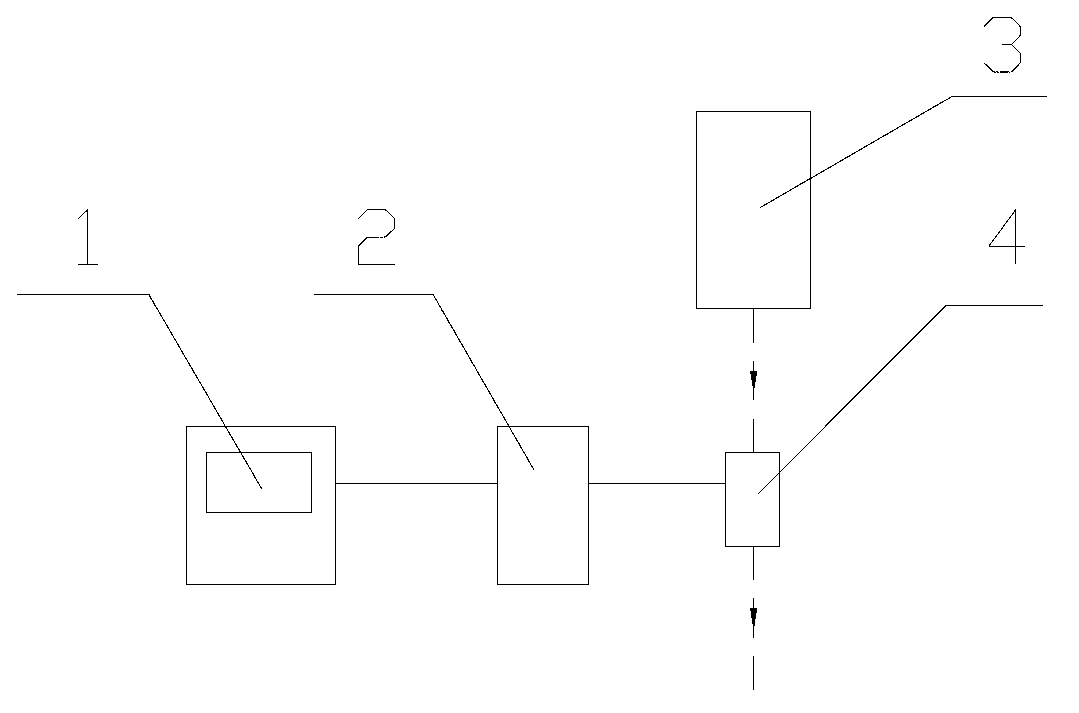

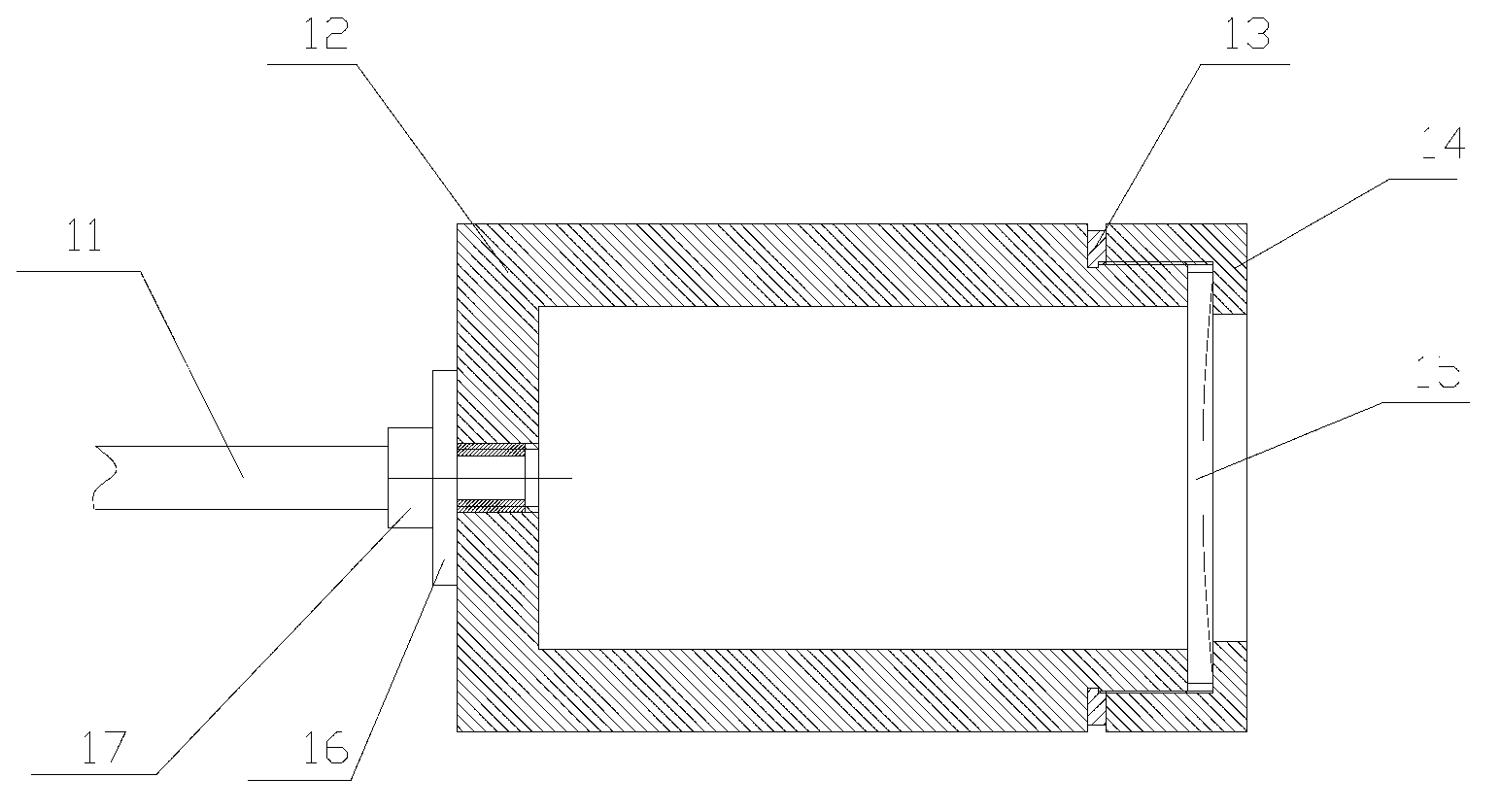

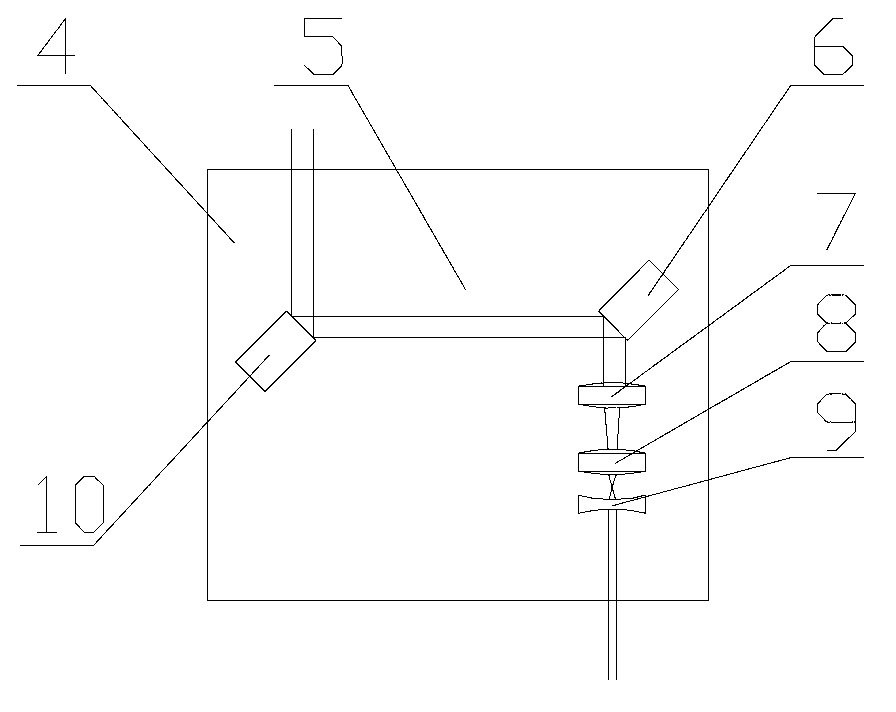

[0025] Such as Figure 1-2 As shown, the laser cutting machine automatic zoom device of the present invention includes an industrial computer 1, a protective gas pressurized pump 2, a laser 3, a first variable curvature reflection device 6, a second variable curvature reflection device 10 and a lens group.

[0026] The industrial computer 1 is connected with the shielding gas booster pump 2 through a control line, and is used to control the air pressure in the cylinder 12 to control the mirror curvature of the first variable curvature reflector 6 and the second variable curvature reflector 10 . The protective gas booster pump 2 is connected to the first variable curvature reflection device 6 and the second variable cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com