All fiber anti-skidding car foot pat and manufacturing method thereof

A technology for car floor mats and manufacturing methods, which is applied to chemical instruments and methods, vehicle parts, and other household appliances, etc., and can solve the problem of poor adhesion between tufts and main carpets, small friction in the contact area, and ugly nails on the main carpet Printing and other problems, to achieve the effect of light weight, increased friction, good sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

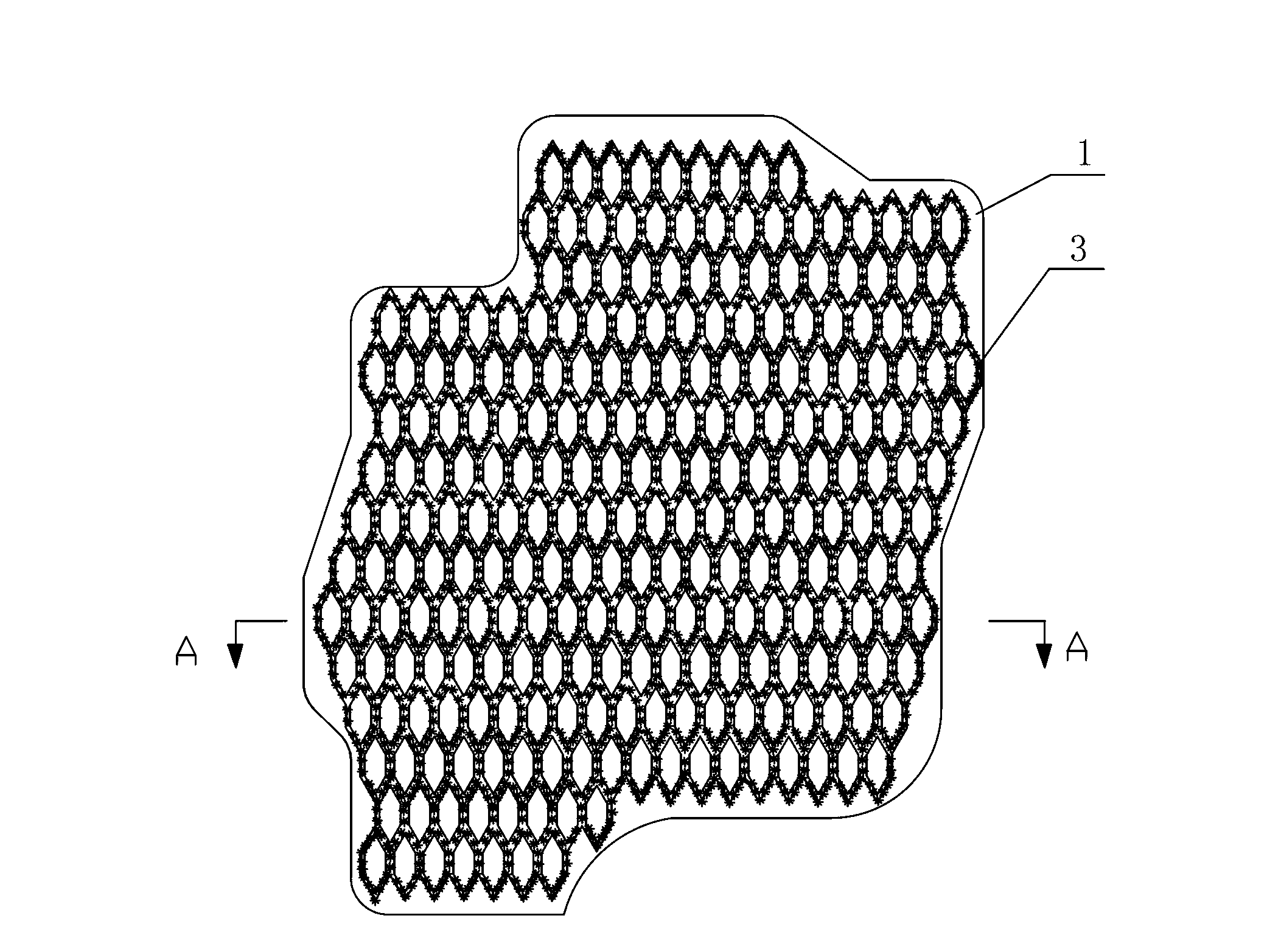

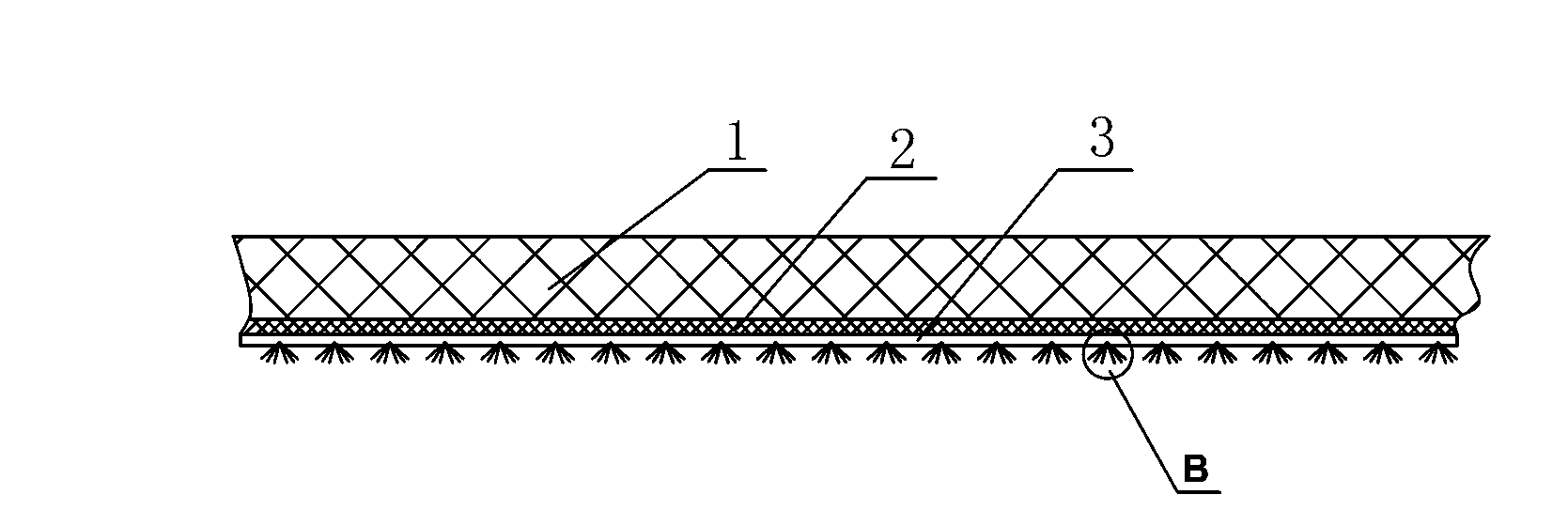

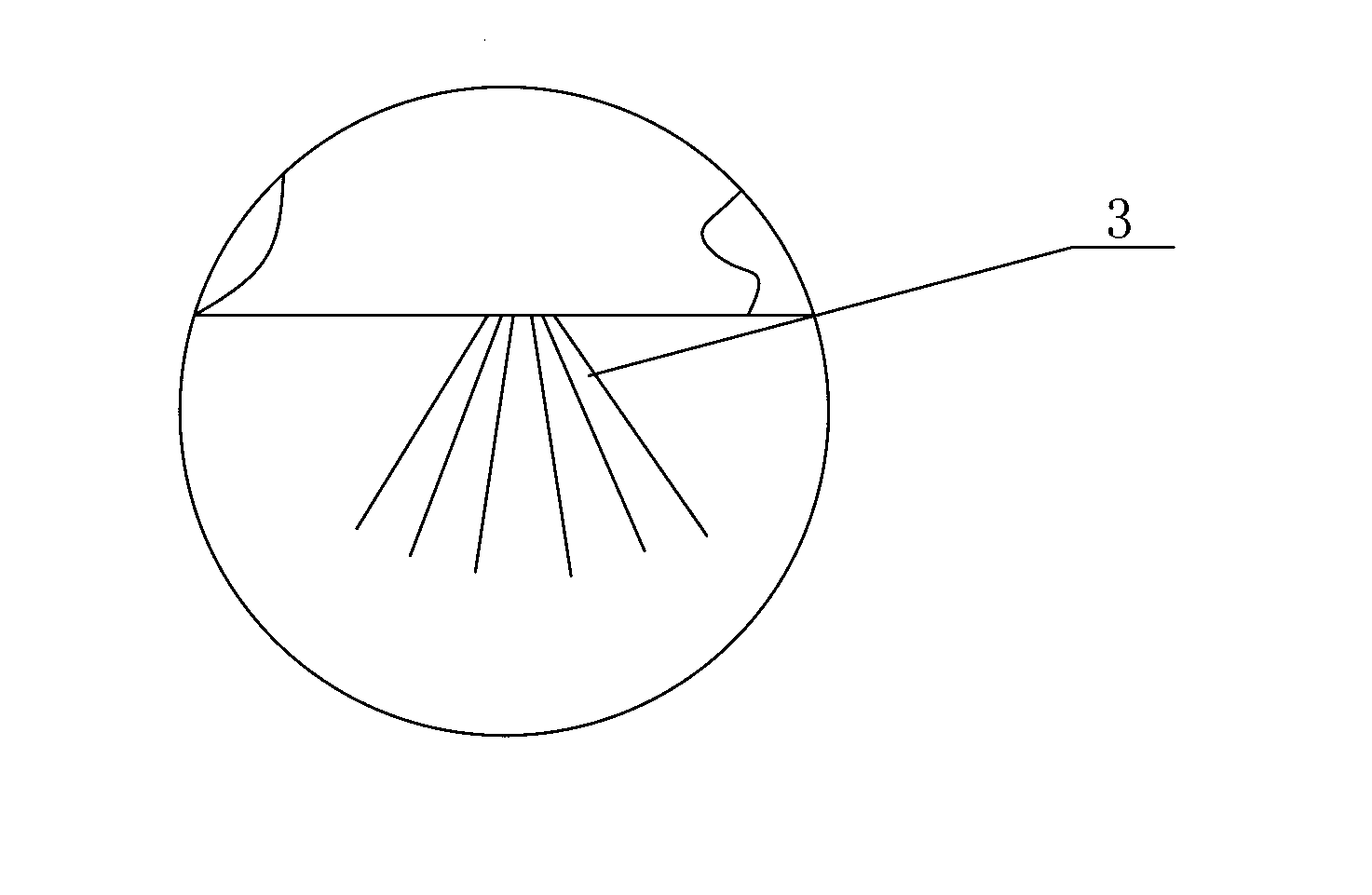

[0026] Such as Figure 1-5 Shown, a kind of all-fiber non-slip automobile floor mat comprises carpet body 1, and the bottom surface of described carpet body 1 is provided with anti-slip layer, and described anti-slip layer passes through foam rubber layer 2 and the bottom surface of described carpet body 1 Fixed; the anti-slip layer is a hedgehog-shaped plastic tuft 3 at the bottom, and the plastic tuft 3 is arranged in a uniform honeycomb shape along the bottom surface of the carpet body 1 .

[0027] The anti-slip layer is a hedgehog-shaped plastic filament cluster 3 at the bottom, which means that the bottom of the anti-slip layer is provided with divergent needles.

[0028] A method for making an all-fiber anti-skid car mat, comprising the following steps:

[0029] 1) Weaving plastic yarn tufts with a warp knitting machine to obtain a non-slip layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com