A preliminary mold for manufacturing small-diameter glass bottles based on the blow-blow method

A glass bottle, small-caliber technology, applied in the direction of blowing-glass blowing molding machine, etc., can solve the problems of difficulty in eliminating the air hoop, not conforming to the thickness ratio of the glass bottle, affecting the mechanical strength of the glass bottle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

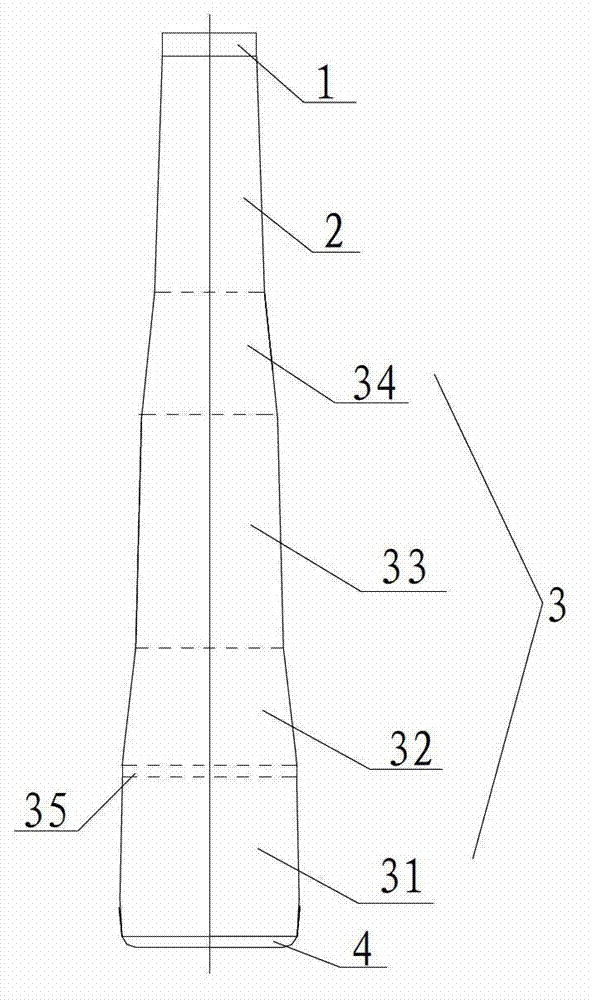

[0021] figure 2 Shown is the initial mold used when manufacturing the 600ml Snowflake brand beer bottle. The cylindrical end 1 has a diameter of 25.3 mm and a height of 6.2 mm; The height is 63 millimeters; the circular platform body 3 is made up of four sections of circular platforms with gradually increasing diameters, and its size from top to bottom is as follows: the diameter of the upper part of the circular platform 34 is 29.5 millimeters, the diameter of the bottom is 36.5 millimeters, and the height is 33.86 millimeters; the diameter of the upper part of the circular platform 33 36.5 millimeters, bottom diameter 39.62 millimeters, height is 62.03 millimeters; Secondary round table 32 upper diameter is 39.62 millimeters, bottom diameter is 46.9 millimeters, height is 31.91 millimeters; End round table 31 upper diameter is 46.9 millimeters, bottom diameter is 47 millimeters, and height is 43 millimeters, The side of the round table is an arc concave inward with a radi...

no. 2 example

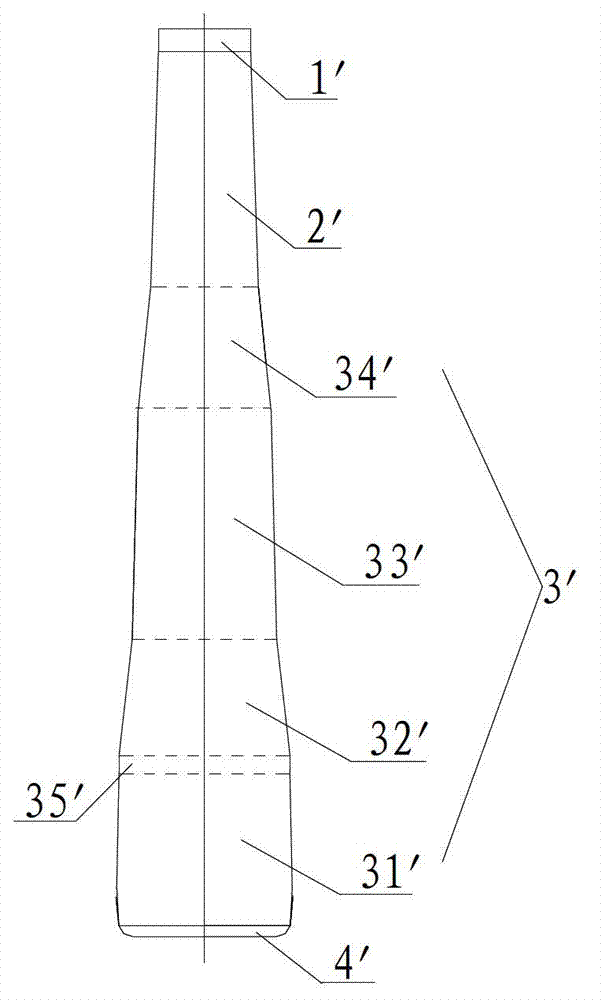

[0023] image 3 Shown is the initial mold used in the manufacture of snowflake beer bottles with a volume of 500ml. The diameter of the cylindrical end 1' is 25.3mm and the height is 4.92mm; mm, and a height of 52 mm; the frustum-shaped body 3' is composed of four segments with gradually increasing diameters, and its dimensions from top to bottom are: the diameter of the upper part of the frustum 34' is 29.66 mm, the diameter of the bottom is 35.52 mm, and the height is 35.49 mm; The upper diameter of the round table 33' is 35.52 mm, the bottom diameter is 36.5 mm, and the height is 25.33 mm; the upper diameter of the secondary end round table 32' is 36.5 mm, the bottom diameter is 45.6 mm, and the height is 63.06 mm; the upper diameter of the end round table 31' is 45.6 mm, and the bottom diameter is 46 mm mm, the height is 42 mm, the side of the round platform is an arc concave inwards with a radius of 150 mm; the height of the air hoop area is 35' and the height is 2 mm, ...

no. 3 example

[0025] Figure 4 Shown is the initial mold used in the manufacture of Snowflake beer bottles with a volume of 580ml. The diameter of the cylindrical end 1'' is 25.3mm and the height is 4mm; It is 30.5 mm and the height is 63 mm; the 3'' of the truncated body is composed of four segments with gradually increasing diameters, and its dimensions from top to bottom are: 33.9 mm; the upper diameter of the round table 33'' is 37 mm, the bottom diameter is 40.6 mm, and the height is 61.93 mm; the upper diameter of the secondary end round table 32'' is 40.6 mm, the bottom diameter is 47 mm, and the height is 30.97 mm; the upper part of the end round table 31'' The diameter is 47 mm, the bottom diameter is 47 mm, and the height is 45 mm. The side of the round platform is an arc concave inward with a radius of 200 mm; the height of the air hoop area is 35'' and the height is 2 mm, and the width from the axis to the outside is 23.5 mm, the radius of the side arc is 30 mm; the height of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com