Arsenic-free low-expansion black and transparent microcrystalline glass

A glass-ceramic, low-expansion technology, applied in the field of glass-ceramic, can solve the problems of not increasing the melting temperature, the melting system is not explained, and the product has many bubbles, etc., to promote dissolution, improve glass nucleation, and reduce interfacial energy. Effect

Active Publication Date: 2013-04-24

ZHEJIANG CHANGXING NOVATECH GLASS

View PDF3 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it was found in production that using SnO 2 Maintain the original melting system, that is, do not increase the melting temperature, the clarification effect is poor, and the product has more bubbles

Therefore, the patented product they describe may not only need to be produced according to their recipe, but there may also be unaccounted for melting regimes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 12

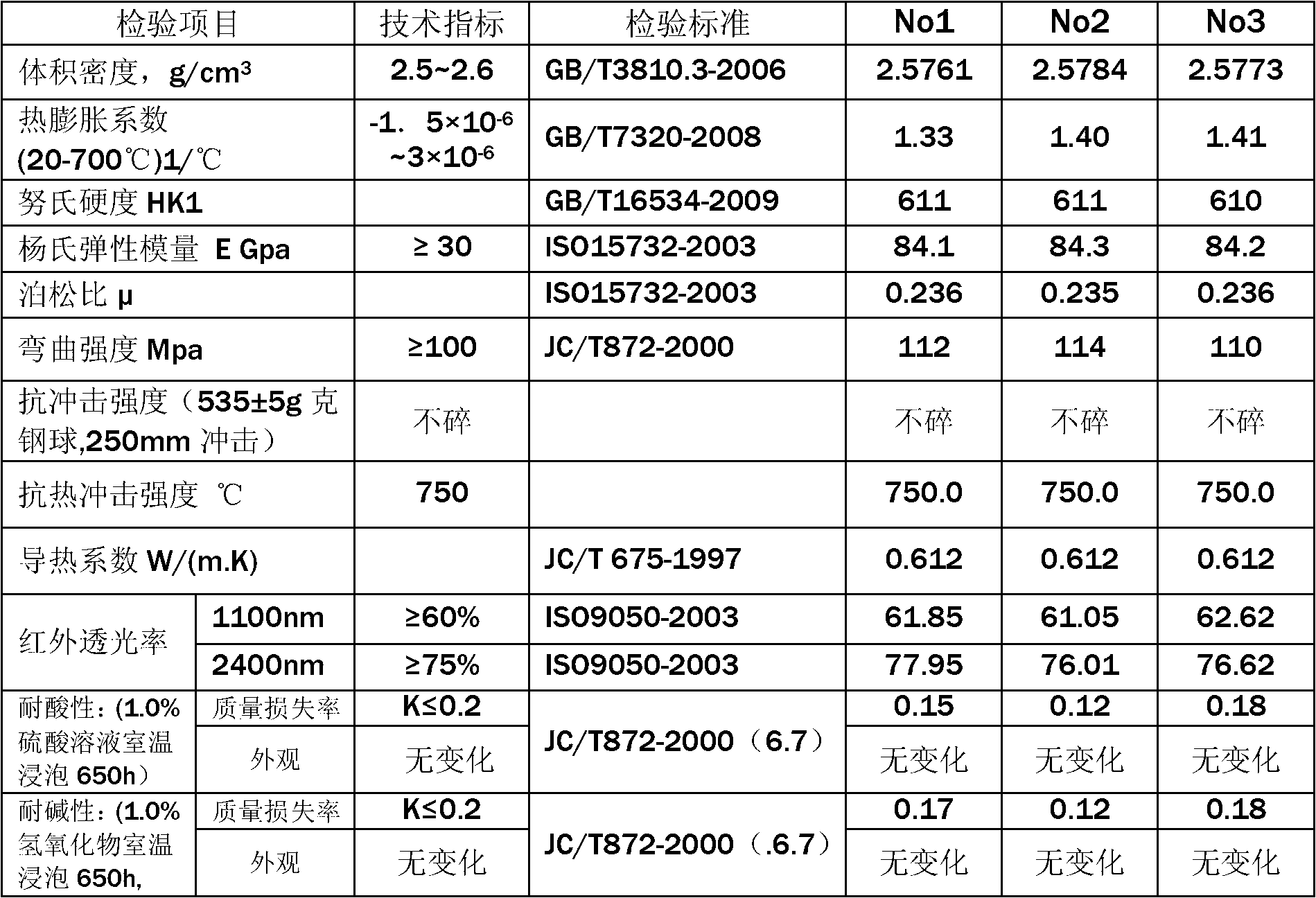

[0037] The specific chemical components of Example 1.2.3 of the present invention are produced according to the above process, and the products obtained are tested according to relevant standards, and the specific data are:

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an arsenic-free low-expansion black and transparent microcrystalline glass. The base components of the microcrystalline glass comprise SiO2, Al2O3, Li2O, CaO, MgO, BaO, ZnO and Na2O+K2O, and the microcrystalline glass also comprises SnO2, CeO2, and MnO or NH4Cl as a clarificant, TiO2 and ZrO2 as a nucleation agent and V2O5 as a colorant. The use of SnO2+CeO2+MnO (or NH4Cl) to substitute As2O3 in the invention ensures good fusing and clarification effects without changing the fusing principle or under a condition that the fusing temperature is not increased, so the microcrystalline glass produced in the invention has the advantages of non-toxicity, environmental protection and high quality, and all the indexes of the physical and chemical performances of the microcrystalline glass accord with international product standard requirements.

Description

technical field [0001] The present invention relates to glass-ceramics. Background technique [0002] At present, the domestic production of glass-ceramics uses As 2 o 3 As a clarifier, but due to the clarifier used As 2 o 3 It is an internationally banned highly toxic substance, which brings great harm to the working environment of workers. [0003] In foreign countries, only the products of Schott in Germany and NEG in Japan do not contain As 2 o 3 , which both use SnO 2 to replace As 2 o 3 . However, it was found in production that using SnO 2 Keeping the original melting system means not increasing the melting temperature, the clarification effect is poor, and the product has more bubbles. Therefore, the patented product they describe may not only need to be produced according to its recipe, but there may also be unaccounted for melting regimes. Contents of the invention [0004] The technical problem to be solved by the present invention is to provide an a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C10/14

Inventor 毛利球

Owner ZHEJIANG CHANGXING NOVATECH GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com