Diatomite compound SBS (Styrene Butadiene Styrene) modified asphalt and preparation method thereof

A technology of modifying asphalt and diatomite, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of small increase in softening point, high cost of modifiers, and high production costs, so as to improve the softening point and soften The effect of point improvement and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

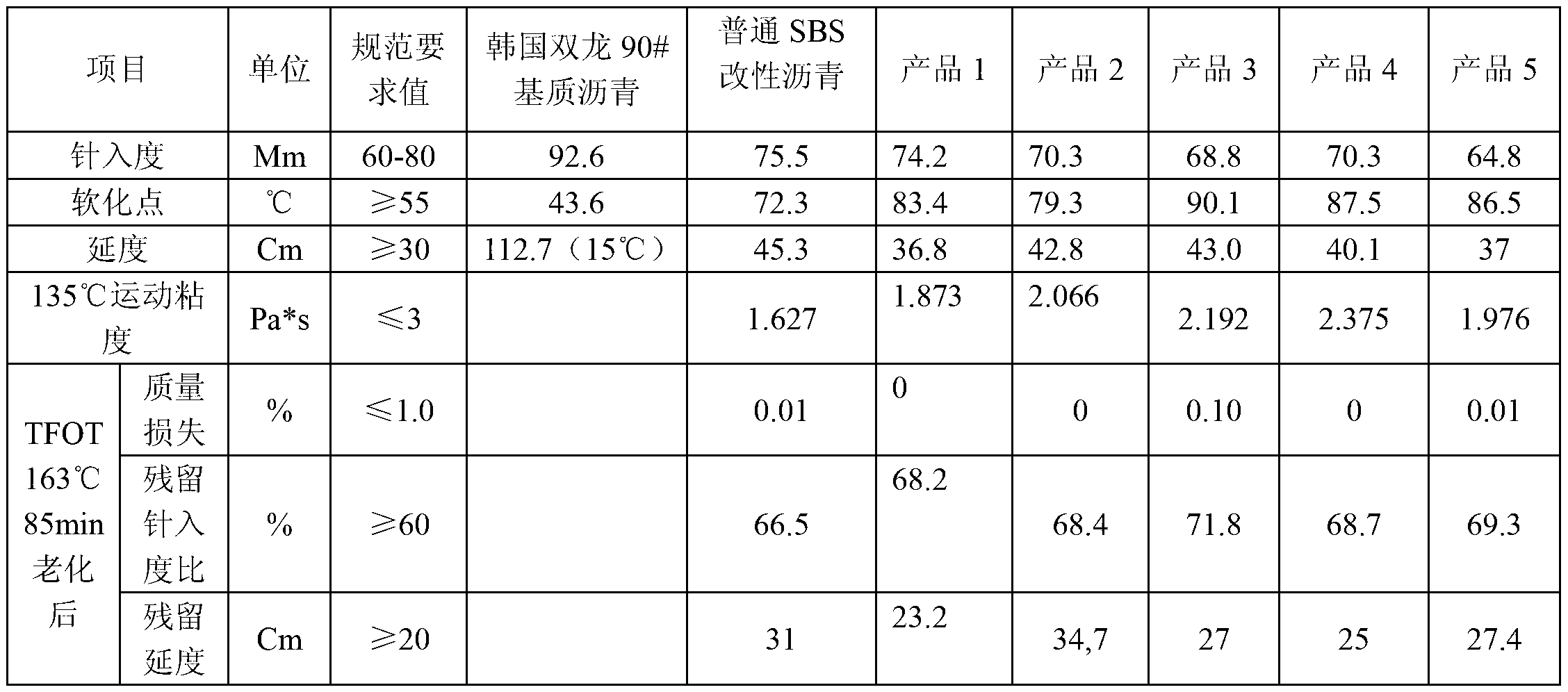

[0027] Example 1 (90# base asphalt 90%, SBS modifier 3%, diatomaceous earth 3%, rubber oil 2%, sulfur 2%):

[0028] Take 450g Korean Ssangyong 90# matrix asphalt and pour it into a beaker, put the beaker into a modified asphalt shearing machine oil bath and heat it to 180°C, start the shearing machine and adjust the speed to 6000r / min, add thermoplastic styrene-butadiene rubber in sequence along the beaker wall 15g of SBS granules, 15g of diatomite granules and 10g of rubber oil, sheared for 2 hours, then stirred for 6 hours in an oil bath environment at 170-175°C, added 10g of sulfur stabilizer, and stirred for 1 hour to obtain a diatomite compound SBS modification Asphalt product 1, its properties are shown in Table 1.

[0029] Comparing the product 1 with the ordinary SBS modified asphalt prepared above, the softening point increased from 72.3 to 83.4, and the ductility was lost but it met the requirements of JTG F40--2004 of "Technical Specifications for Construction of Hi...

Embodiment 2

[0030] Example 2 (90# base asphalt 90%, SBS6%, diatomaceous earth 1%, rubber oil 1%, sulfur 2%):

[0031] Take 450g Korean Ssangyong 90# matrix asphalt and pour it into a beaker, put the beaker into a modified asphalt shearing machine oil bath and heat it to 180°C, start the shearing machine and adjust the speed to 6000r / min, add thermoplastic styrene-butadiene rubber in sequence along the beaker wall 30g of SBS particles, 5g of diatomite and 5g of rubber oil, sheared for 2 hours, stirred in an oil bath environment at 170-175°C for 6 hours, added 10g of sulfur stabilizer and stirred for 1 hour to obtain diatomite compound SBS modified asphalt product 2. Its performance is shown in Table 1. Compared with the ordinary SBS modified asphalt prepared under the same conditions, the softening point of product 2 is slightly improved. Because there is not enough diatomite filled in the network structure of SBS to absorb and swell the light components, the softening point does not incre...

Embodiment 3

[0032] Example 3 (90# base asphalt 85%, SBS6%, diatomaceous earth 4%, rubber oil 3%, sulfur 2%):

[0033] Take 425g Korean Ssangyong 90# matrix asphalt and pour it into a beaker, put the beaker into a modified asphalt shearing machine oil bath and heat it to 180°C, start the shearing machine and adjust the speed to 6000r / min, add thermoplastic styrene-butadiene rubber in sequence along the beaker wall 30g of SBS particles, 20g of diatomite, 15g of rubber oil, sheared for 2 hours, stirred in an oil bath environment at 170-175°C for 6 hours, added 10g of sulfur stabilizer and stirred for 1 hour to obtain diatomite compound SBS modified asphalt product 3. Its performance is shown in Table 1. Compared with the ordinary SBS modified asphalt prepared under the same conditions, the softening point index of product 3 has been greatly increased from 72.3°C to 90.1°C, and the loss of ductility is very small. Product 3 is especially suitable for tropical high-temperature climate areas H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com