Vulcanization method of catalyst used in wax oil hydrotreating process

A wax oil hydrogenation and treatment process technology, which is applied in the field of oil refining enterprises including residual oil hydrogenation process equipment, can solve the problems such as not considering the joint operation of multiple sets of hydrogenation equipment, and achieve considerable economic and social benefits and good safety , The effect of simple start-up operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

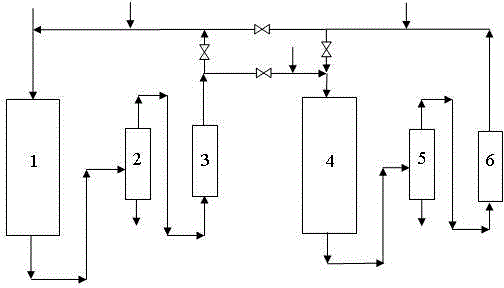

[0047] Stable operation of the residual oil treatment unit. After the circulating hydrogen is mixed with the residual oil raw material, it passes through the residual oil hydroprocessing unit 1 and enters the reaction product gas-liquid separator 2 of the residual oil hydroprocessing unit to separate the gas from the generated oil. The gas passes through the residual oil The oil hydrotreating unit circulates hydrogen to the hydrogen desulfurization unit 3 and returns to the residual oil hydrotreating unit 1 . At the same time, the FF-14 catalyst is loaded into the hydrotreating reactor, dried, and then airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0 MPa, the temperature is adjusted to 160°C, and sulfurized oil is introduced. After the bed temperature is stable, adjust the circulating hydrogen dehydrogenation unit 3 of the residual oil hydrotreating unit, and the circulating hydrogen containing hydrogen sulfide is introduced into...

Embodiment 2

[0049] Stable operation of the residual oil treatment unit. After the circulating hydrogen is mixed with the residual oil raw material, it passes through the residual oil hydroprocessing unit 1 and enters the reaction product gas-liquid separator 2 of the residual oil hydroprocessing unit to separate the gas from the generated oil. The oil hydrotreating unit circulates hydrogen to the hydrogen desulfurization unit 3 and returns to the residual oil hydrotreating unit 1 . At the same time, the FF-14 catalyst is loaded into the hydrotreating reactor, dried, and then airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, and the temperature is adjusted to 180°C. At this time, adjust the circulating hydrogen dehydrogenation unit 3 of the residual oil hydrotreating unit, and the circulating hydrogen containing hydrogen sulfide is introduced into the wax oil hydrotreating unit 4 for sulfidation, and then passes through the reaction produc...

Embodiment 3

[0051] Stable operation of the residual oil treatment unit. After the circulating hydrogen is mixed with the residual oil raw material, it passes through the residual oil hydroprocessing unit 1 and enters the reaction product gas-liquid separator 2 of the residual oil hydroprocessing unit to separate the gas from the generated oil. The oil hydrotreating unit circulates hydrogen to the hydrogen desulfurization unit 3 and returns to the residual oil hydrotreating unit 1 . At the same time, FF-14 is loaded into the reactor, dried, and then airtight. After the airtightness is qualified, the hydrogen partial pressure is adjusted to 14.0MPa, the temperature is adjusted to 160°C, and vulcanized oil is introduced. After the bed temperature is stable, adjust the circulating hydrogen dehydrogenation unit 3 of the residual oil hydrotreating unit, and the circulating hydrogen containing hydrogen sulfide is introduced into the wax oil hydrotreating unit 4 for sulfidation, and then passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com