A prefabricated pavement structure and a Z-shaped rubber insert for the structure

A pavement structure and rubber technology, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of non-reusability, waste of energy, water and sand and gravel materials, long working cycle, etc., to achieve integrity and continuity, increase the resistance to compression and deformation, and reduce the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

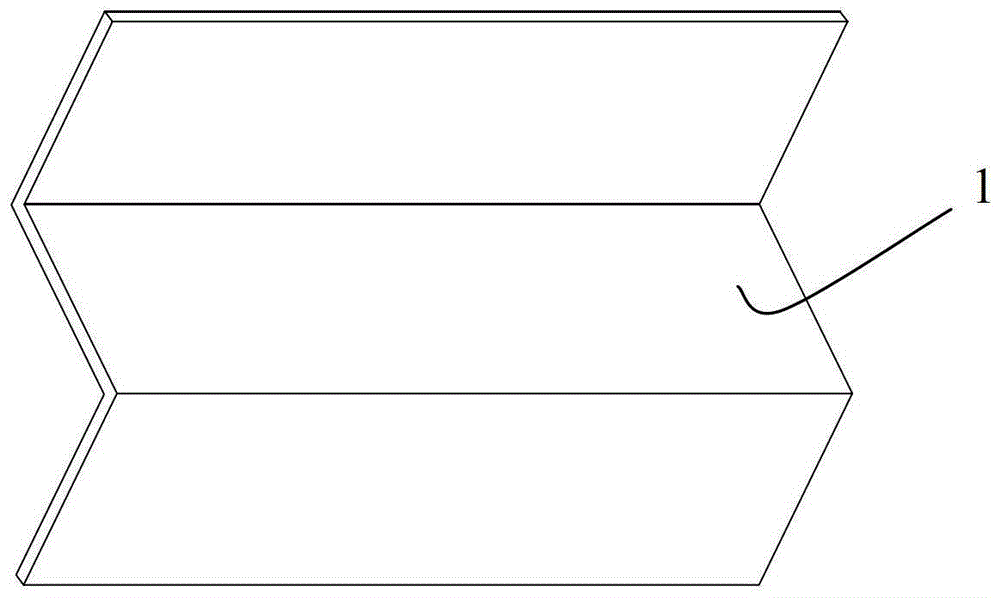

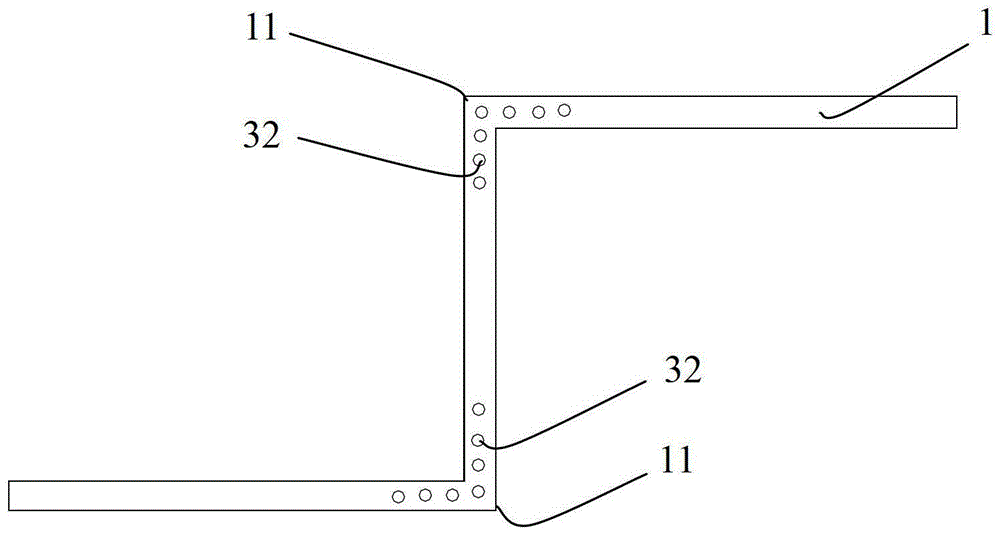

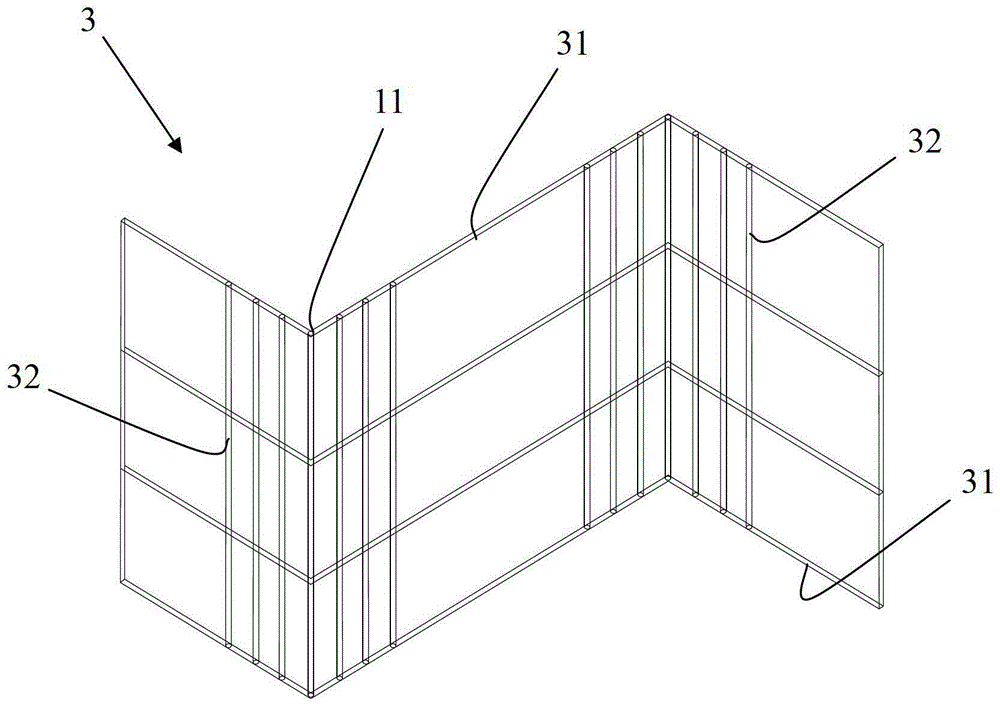

[0016] combine Figure 1 to Figure 3 As shown, the Z-shaped rubber insert 1 of the prefabricated pavement structure of the present invention is used for the isolation between the splicing surfaces of the concrete T-shaped prefabricated block 2, and the spacing of the three equilateral right-angled grooves of the rubber insert 1 is 5mm. The Z-shaped rubber insert 1 includes an insert skeleton 3 and rubber coated on the outer layer of the insert skeleton 3. The insert skeleton 3 starts from the center of the corner and along two vertical bending directions at equal intervals. A transverse stiffening steel wire 31 with a diameter of 2 mm, and a plurality of longitudinal stiffening steel wires 32 are arranged in the longitudinal direction of the insert frame 3. First, a longitudinal stiffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com