Counter pull type impact piling machine

A pile sinker and back-pull technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of easy cracking of pile tops, small impact energy of pile sinkers, and high pile frames, making it difficult to crack and break , reduce the height of the pile frame, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

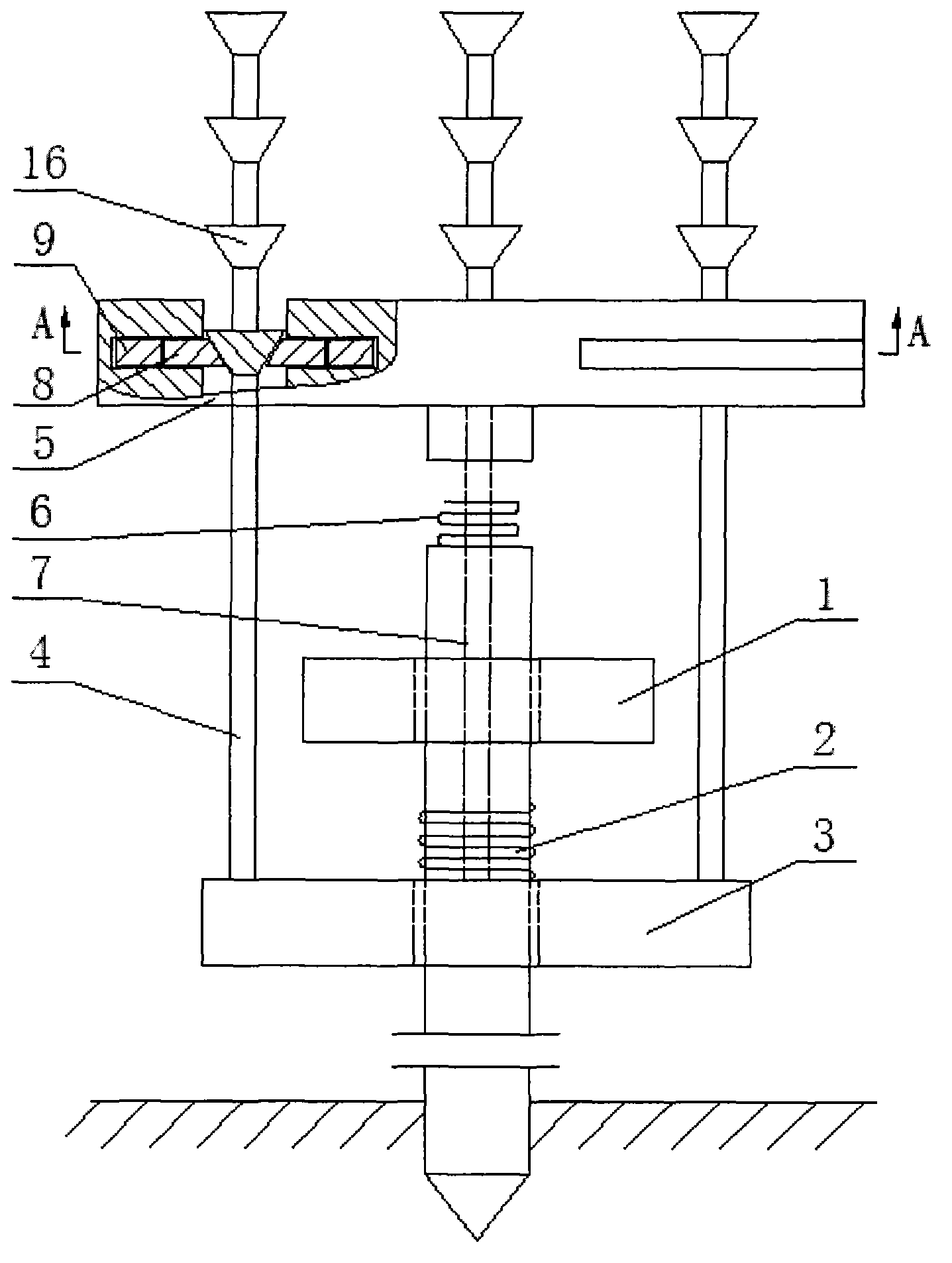

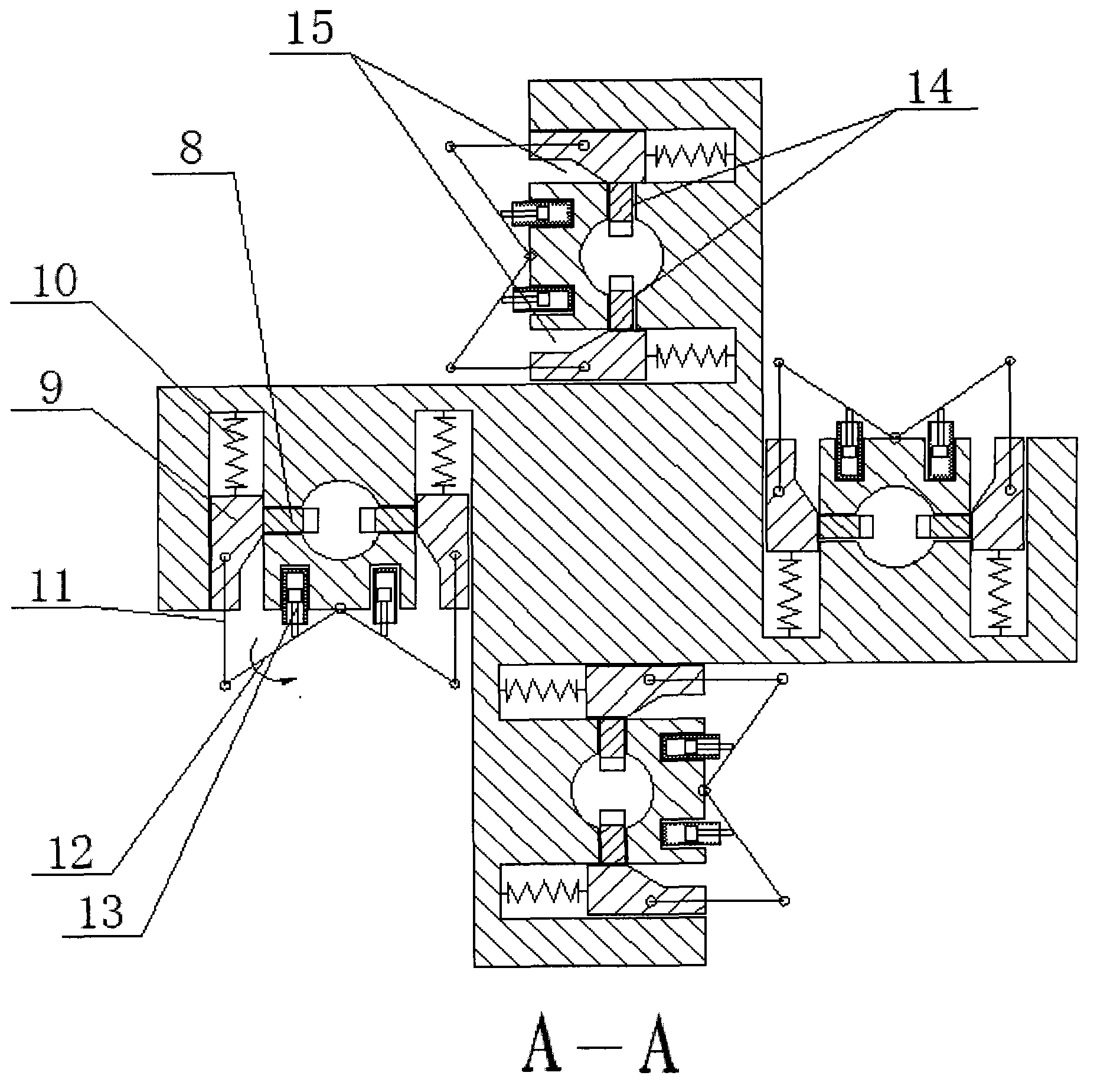

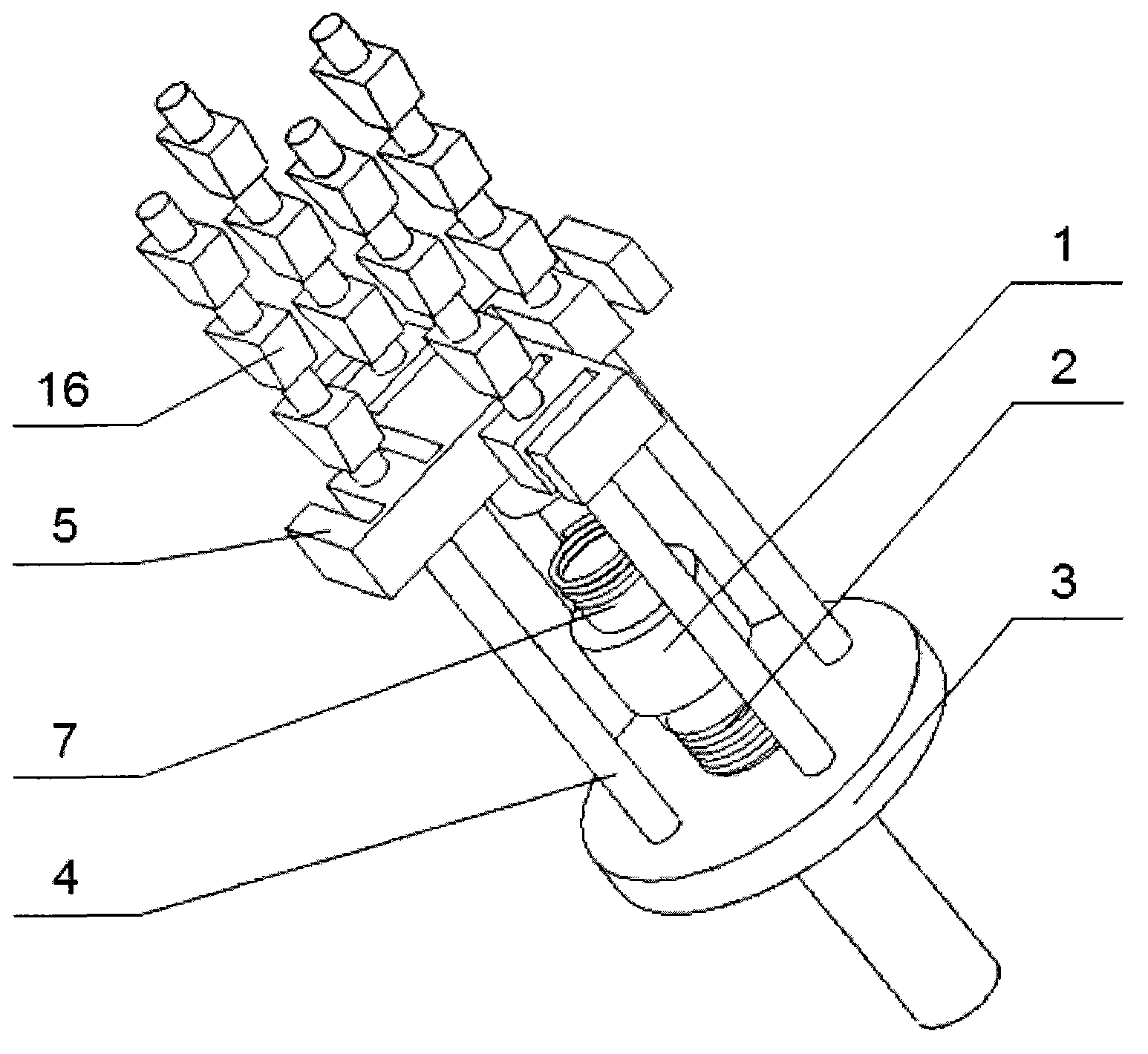

[0024] Such as figure 1 and image 3 As shown, the anti-pull impact pile driver of the present invention includes an impact hammer 1, a tension and pressure box 3, four pull rods 4, a pile cap 5, four sets of pull rod clamping mechanisms and a set of external power source (not shown) out). Among them, the impact hammer 1 is located above the tension and compression box 3, and both the impact hammer 1 and the tension and compression box 3 are provided with a coaxial central hole for the prefabricated pile 7 to freely pass through, and the external power source is connected with the impact hammer 1 to drive the impact. The hammer performs the impact. The pile cap 5 is located above the impact hammer 1, and four sets of pull rod clamping mechanisms are evenly distributed inside the pile cap 5, and each set of pull rod cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap