Tunnel arch foot circumferential high pressure jet strengthening method and construction equipment

A technology of high-pressure jetting and construction equipment, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as water blocking, soil retention and sand consolidation, and achieve the effect of reducing reinforcement costs, ensuring integrity, and a good water-proof and sand-fixing curtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

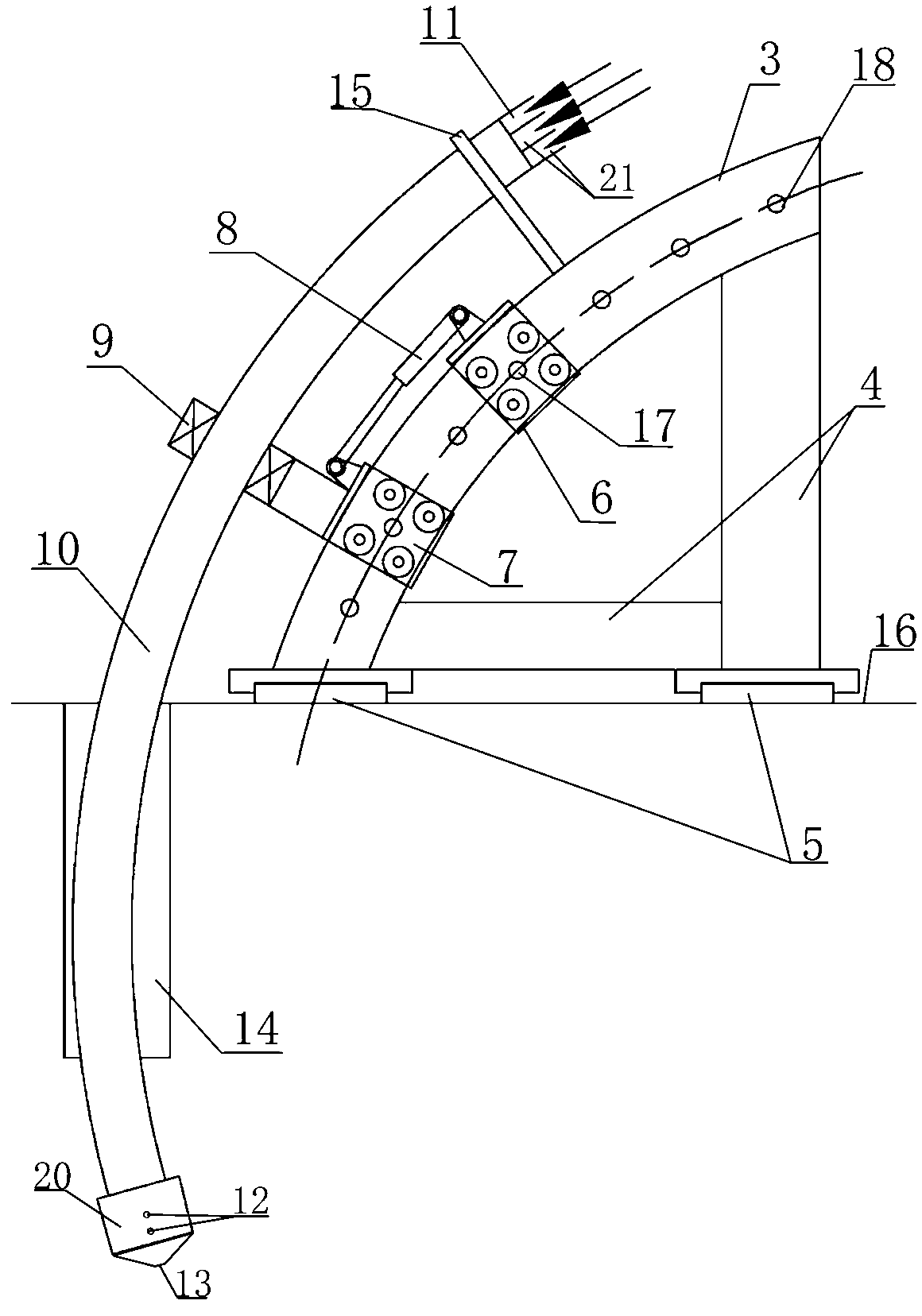

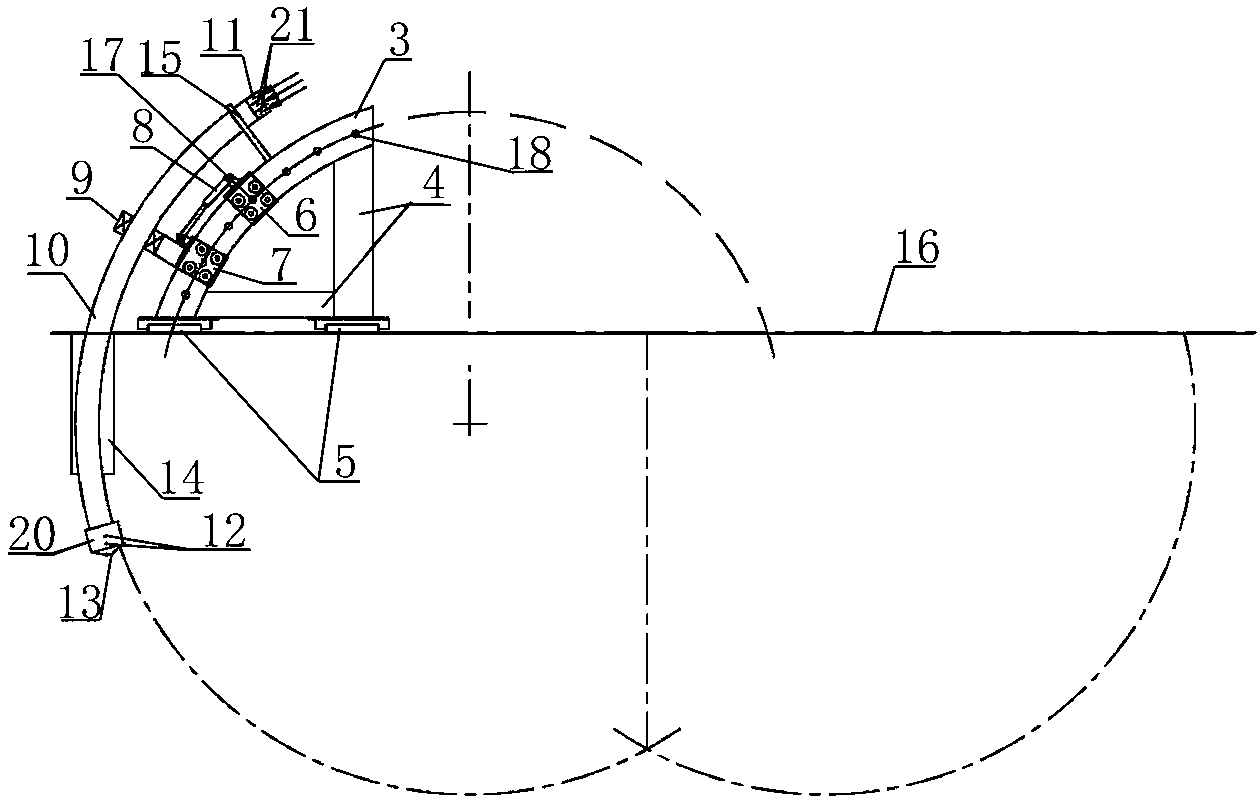

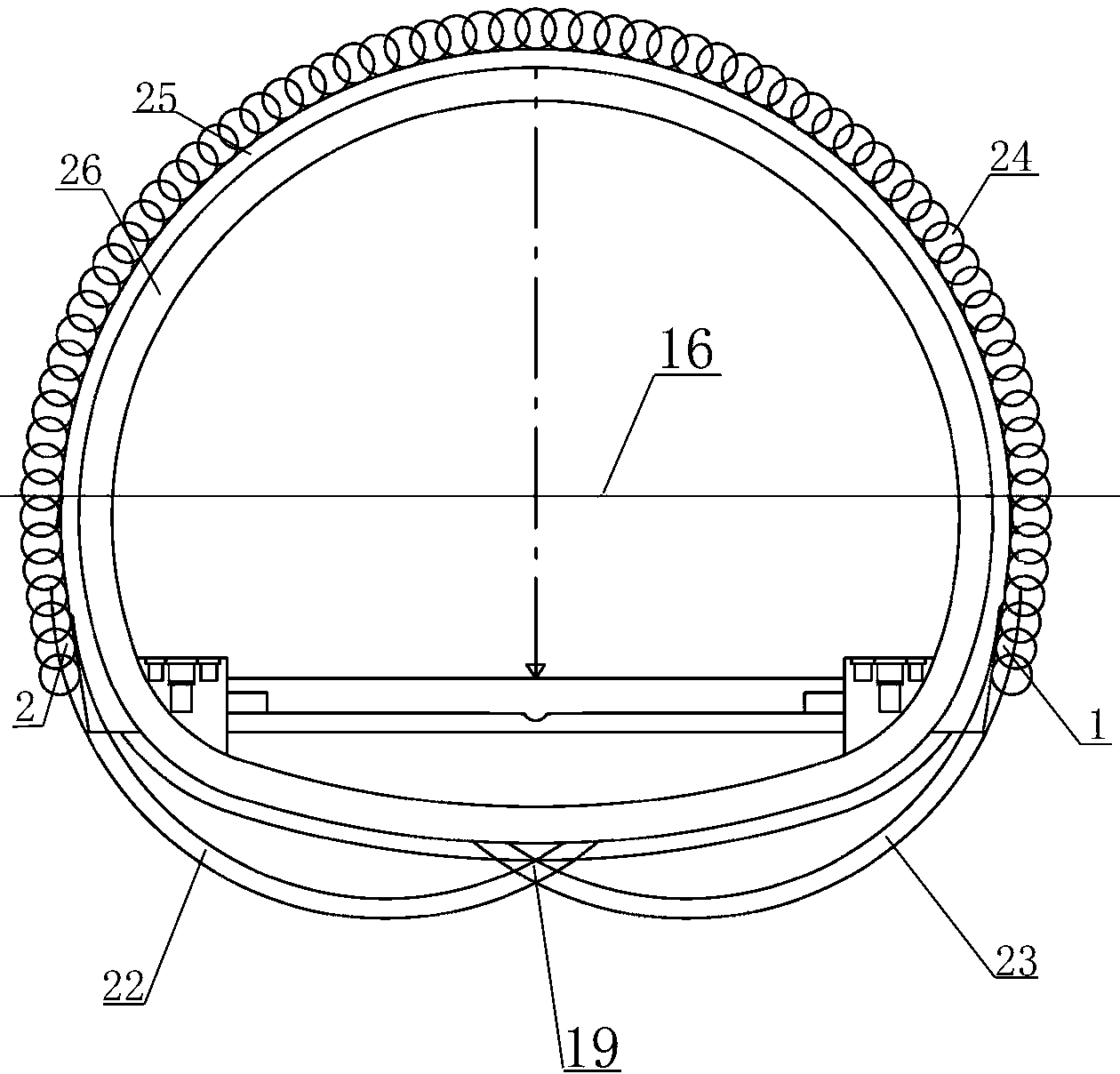

[0037] Examples see figure 2 with image 3 As shown, among them, figure 2 The dotted line in represents the trajectory of the curved drill pipe in the construction equipment. A high-pressure injection reinforcement method for tunnel arch foot ring, the steps are as follows:

[0038]Step 1: Take the excavated upper step or middle step as the construction step surface 16, use a hole opener to symmetrically tunnel axis on both sides of the construction step surface 16, and drill two rows of arc-shaped drill pipes 10 into the ground according to the design requirements 14;

[0039] Step 2, fix the rack guide rail 5 on the left side of the construction step surface 16 according to the installation size, fix the rack 4 with the fixed carriage 6 and the movable carriage 7 on the rack guide rail 5, and complete the first The arc-shaped drill pipe 10, the nozzle 20, the high-pressure water pipe 11, and the high-pressure cement slurry pipe 21 are connected, and then the clamper 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com