Light diffusion materials and preparation method thereof

A light-diffusing, light-transmitting material technology, applied in the field of materials and chemistry, can solve problems such as light transmittance decline, and achieve high light transmittance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

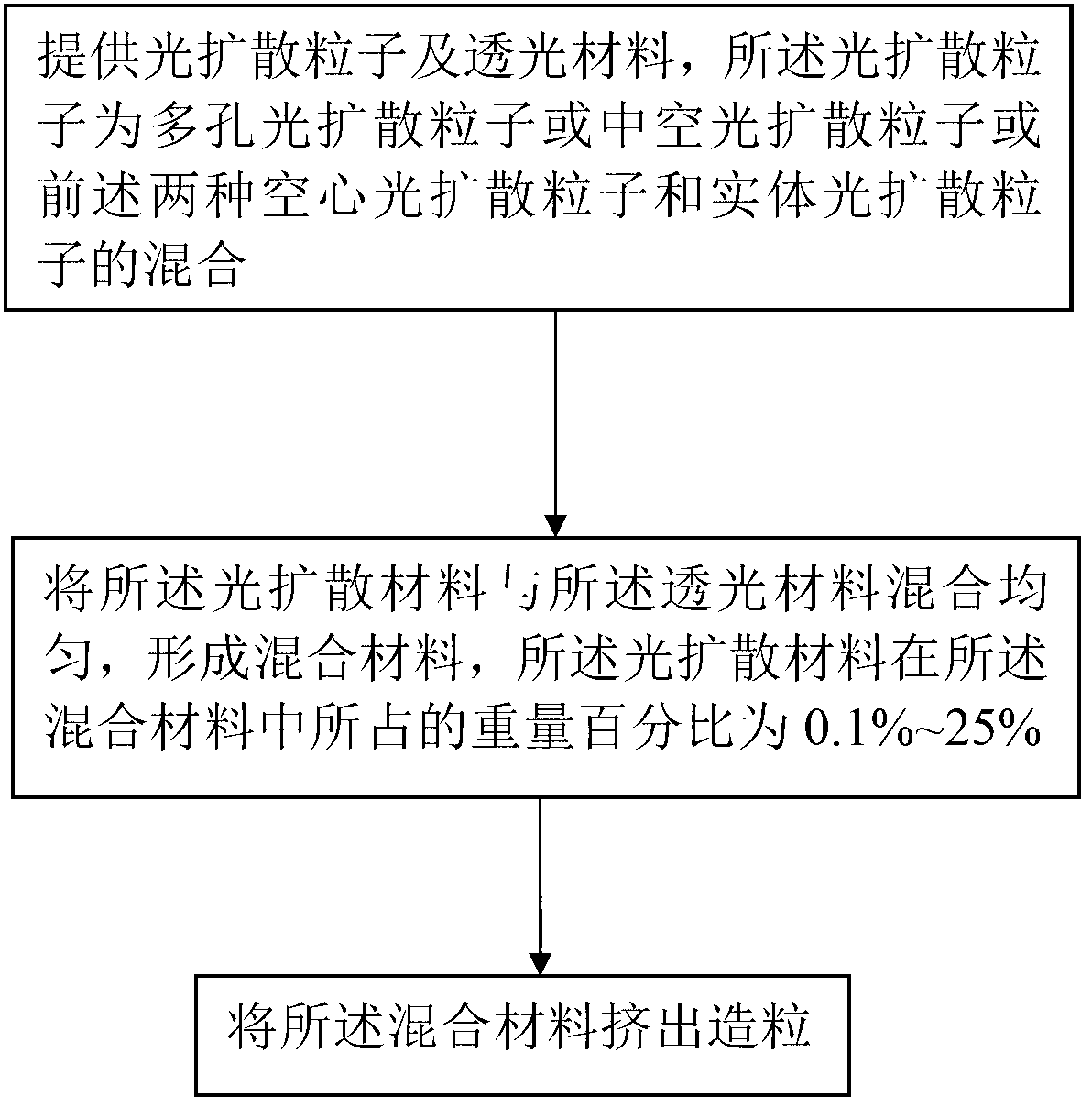

[0019] The present invention also provides a method for preparing the light-diffusing material, comprising the steps of:

[0020] Step 1: Provide light-diffusing particles and light-transmitting materials. The light-diffusing particles are porous light-diffusing particles or hollow light-diffusing particles or a mixture of the aforementioned two kinds of hollow light-diffusing particles and solid light-diffusing particles.

[0021] Step 2: uniformly mix the light-diffusing material and the light-transmitting material to form a mixed material, and the weight percentage of the light-diffusing material in the mixed material is 0.1%-25%.

[0022] The third step: extruding the mixed material into granules.

[0023] The preparation method of the light-diffusing material also includes uniformly mixing the light-diffusing material with auxiliary agents before performing the second step, and the auxiliary agents include fluorescent whitening agents, anti-ultraviolet auxiliary agents, ...

Embodiment 1

[0030] 0.5 parts by mass of the porous light-diffusing particles are weighed, and the porous light-diffusing particles are porous organic silicon microspheres. And weigh 99.5 parts by mass of the light-transmitting material, which is polycarbonate. Stir the above two materials evenly, and put them into a melt extruder for blending and granulation. The temperature range of extrusion granulation is 180℃~300℃. The porous light-diffusing particles are uniformly dispersed in the polycarbonate substrate, and the particle diameter ranges from 0.3 to 5 μm.

[0031] When the light-diffusing polycarbonate material has a haze of 97%, the light transmittance reaches 86%.

Embodiment 2

[0033] 20 parts by mass of the porous light-diffusing particles are weighed, and the porous light-diffusing particles are porous organic silicon microspheres. And weigh 80 parts by mass of the light-transmitting material, the said light-transmitting material is polycarbonate, stir the above two materials evenly, and put them into the melt extruder for blending and granulation. The temperature range of extrusion granulation is 180℃~300℃. The porous light-diffusing particles are evenly dispersed in the polycarbonate substrate, and the particle diameter ranges from 0.3 to 5 μm.

[0034] When the light-diffusing polycarbonate material has a haze of 99%, the light transmittance reaches 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com