Method for applying CAD (computer-aided design) drawing to precision finger-type milling cutter for involute gears

An application method, involute technology, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In conjunction with the accompanying drawings, the present invention is further described in detail through the embodiments.

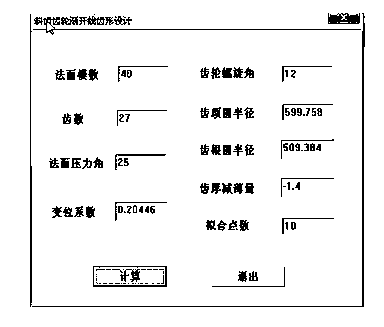

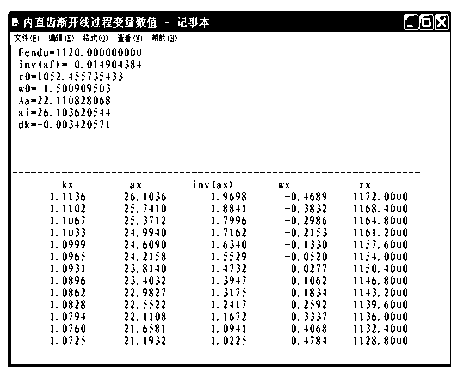

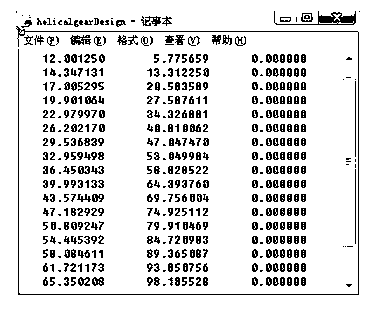

[0045] The CAD drawing application method of the involute gear fine finger milling cutter described in this embodiment is to construct a tool CAD system based on the UG platform for the actual production requirements of the involute gear fine finger milling cutter. By inputting the finger milling cutter Various 3D parameters of various 3D parameters are generated to generate 3D solid models. Through the analysis and summary of 3D parametric technology, the 3D model and 2D CAD graphics of involute gear fine finger milling cutter are realized by using parametric technology and UG secondary development technology. Automatic generation and automatic labeling of dimensions. The involute gear precision finger milling cutter includes straight teeth and helical teeth.

[0046] The process of generating the finger milling cutter is: input the parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com