Scram button switch

A button and switch technology, applied in the direction of contact operating parts, etc., can solve the problems of complex structure and many accessories of emergency stop switch, and achieve the effect of simple structure and few accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

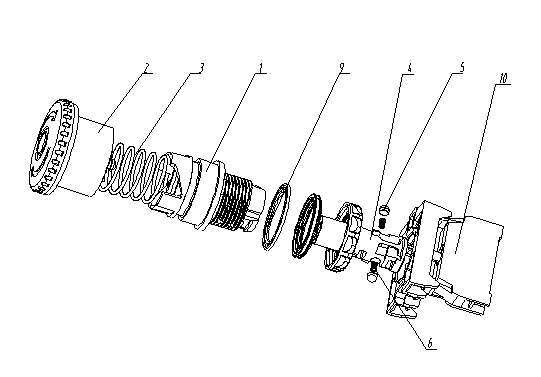

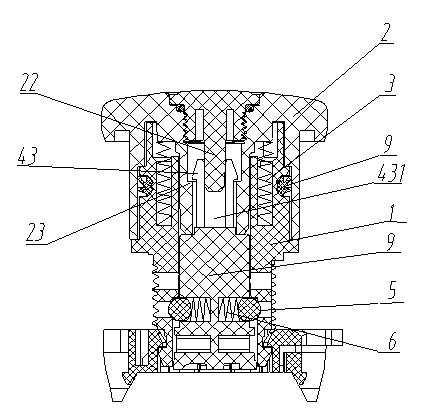

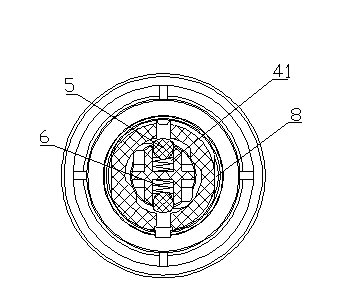

[0037] Such as figure 1 , figure 2 , image 3 , Figure 8 , Figure 9 Shown is the emergency stop button switch of the present invention, which includes a housing 1, a button 2, an operating member 4 and a locking device, wherein the operating member 4 is slidably arranged inside the housing 1, and the operating member One end of 4 is connected to the button 2, and a return spring 3 is arranged between the button 2 and the housing 1; the other end of the operating part 4 controls the contact or non-contact of the dynamic and static contacts in the base 10 to realize The circuit is switched on and off; the locking device is arranged between the operating member 4 and the housing 1, the locking device includes a slot 7 formed on the housing 1, and is arranged on the operating member 4 The locking piece 5 and the elastic piece 6 in the transverse groove 41; the locking piece 5 is a strip-shaped part, one end of which is a working end, and the working end is suitable for bein...

Embodiment 2

[0046] This embodiment is a preferred form of the above embodiment, the locking member 5 is a cylinder with both ends of an arc surface structure, one end surface is a hemispherical surface, and the other end surface is an arc surface with a radius of curvature greater than the radius of the hemispherical surface , when the hemispherical side is matched with the slot 7, the cylinder is in point contact with the edge of the slot 7, and when the arc side is matched with the slot 7, the cylinder and the slot The upper end surface of the card slot 7 is in contact.

[0047] When the emergency stop button switch is set to pull type, as image 3 As shown, the arc surface end of the hemispherical surface of the locking member 5 is the working end, and the other end of the locking member 5 is connected to the elastic member 6. When locking, the hemispherical surface side cooperates with the card groove 7 , the cylinder is in point contact with the edge of the slot 7 .

[0048] When t...

Embodiment 3

[0050] This embodiment is the preferred mode of embodiment 1, such as Figure 5 and Figure 6 As shown, the locking member 5 is a circular frustum with both ends of the arc surface structure. In contact, when the arc surface on the side with a larger cross section fits with the locking groove 7 , the frustum of the cone contacts the upper end surface of the locking groove 7 . The radius of curvature of the arc surface on the side with the smaller cross section is smaller than the radius of curvature of the arc surface on the side with the larger cross section.

[0051] When the emergency stop button switch is set to pull type, as Figure 5 As shown, the arc surface end on the side with a small cross-sectional area of the locking member 5 is the working end, and the arc surface on the side with a large cross-section of the locking member 5 is connected to the elastic member 6. When locking, the locking The arc surface end on one side with a small cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com